Mike - Since the LFS is not suitable for our application on the NDW-23A are you still certain that the TS-300 is the wrong way to go?

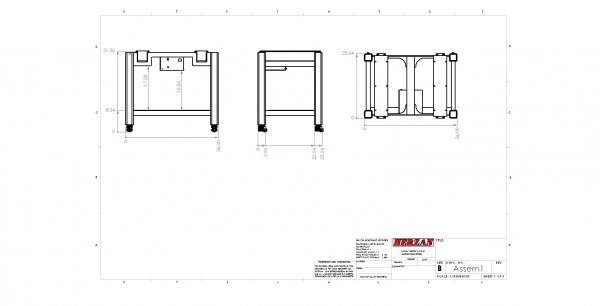

I still am considering the TS-300 because the stand for it can match my other stands and I could buy the TS-300 in the future and just drop it in if I wanted to experiment in the future wih active isolation.

Why is active leveling of no use to us with the AS turntable?

the TS-300 starts at $5k+ more than the NDW-23A lists for, and you still need a table......so depending on that table that could be quite a bit more. the NDW-23A is ready to go as is.

manual leveling is quite easy. ask Tim for the YouTube link for the AVI leveling. piece of cake. and ask Tim about what advantage active leveling offers.

the only advantage would be you could get a standard table then add the TS-300 later.