Lampizator Valve / Tube Rolling Review Thread

- Thread starter Zero000

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi everybody, some things to consider when tube rolling.

1. Never trust internet opinions, because every circuit is different and every operating point is different, hence there is no defined specific tube sound and disappointment can be lurking on the horizon. By far the best way to save huge money losses is to borrow before buying. Trying in YOUR SYSTEM not in your friend's system.

2. Listen to your equipment manufacturer advices. We for example have 40 different tube types to try and when we choose one - it is because it sounds best. Anybody as a hobbyist, privately - cant try so many tubes and what do you do with the "not selected" ones afterwards ?

3. used tubes of DHT type should be forbidden from shipping. Their cathode is a thin tungsten or other metal string, which gets VERY fragile with hours of usage. So a tube may be 50 years old, of which 20 years it was used, their guts are more fragile than faberge egg. So if you get this 1000$ tube and it crackles - the seller will say SORRY - it was perfect when I shipped it. New tubes can be shipped safely, but not old.

4. "Brands" do not guarantee any consistency. Similar tubes have been made by any plant for many different brands, also companies helped each other and made for each other complementary portfolio positions, for example Haarlan plant made the legendary ECC182 for Valvo, Philips, Siemens, Mullard, Amperex and probably some other as well. There is no such thing as a Philips sounding better than valvo. Also easch plant buys materials from many sources, and one metal is not the same as another metal, so especially across the plants and across the time - tubes hugely varied.

5. The so called getters are not getters, they are getter generators. What people refer to as getters - do not play any role, do not play any music, do not influence the sound, dont have any influence on anything whatsoever. It may however make some sens if a different tube tybe has a different shape of "getter" that may indicate overall assembly difference and it may mean a diferent sound. Thats how we can interpret saying like: the 6SN7 with D shape getter sounds better than the one with O getter. For the record: a getter is the silver shiny mirror stuff on the glass - a deposit of ions.

6. If you have say a Lampizator DAC and you buy a super precious set of DHT tubes, what you do is called sometimes "tube training" or "regeneration". You wanna gently bring to life a tube that maybe spend 30 years doing nothing. To collect all unwanted gasses and put them on the getters and not enjoy fireworks - you first do heating session without power applied to anode. You do this: first, remove the rectifier tube from the amp or DAC to "remove" high voltage component of the anode supply. This way the music tubes will be fed with heater only. Then set the DAC heater switch to the lowest current available (the furthest from 300B which is always the highest). (I mean even if it is actually a 300B use the lowest "wrong" setting). Instert the newly acquired unknown condition tubes. Keep them warm for 24 hrs. After that, if there is a "correct" setting for the new tubes thats not the one you used - we call it nominal - use that another 24 hrs. After the total of 48 hrs insert the rectifier tube (while DAC is ON) and let it warm up. Very slowly the new tubes will be given anode high voltage and will start conducting the current.

7. Remember, the current is flowing in the tube from bottom - up. From Cathode to anode - the whole magic of tube operation happens IN THE CATHODE , the electron generation and emission to the space around the wire, which in this case is the filiament - the tiny glowing string. That is your tube! Magic happens! The whole black box inside is just anode - almost unimportant. It only collects the electrons and sends them to the ground. So it doesnt matter if the tube has black anode, grey anode, shiny anode etc - the CATHODE is far far more important. But we practically can't see it, so nobody discusses it.

8. You can easily measure many tube and circuit parameters using only the simplest voltmeter from Home Depot. Having said that, every audiophile worth his salt MUST have a real meter. It only cost 50-80 Euro and it will last a lifetime. For example UNI-T UT70B is an example of an excellent high end but cheap meter. So once you have any meter, you can gently pull the tube up by 1 cm or 1/4 inch and gain access to the pins and there are MANY things you can measure: bias current, bias voltage, grid voltage, heater current, heater voltage, anode voltage, signal gain, cathode voltage, incoming signal strength, outgoing signal level, even to some degree - the output impedance. Just a meter and 10 minutes of work to do all that. No tools required.

9. You can swap rectifier tubes while listening - there is no pop, no click, and no damage to the tube, no damage to the equipment. Just use a glove.

10. it is ok to touch the tubes with your hand (when it is cold !) , no need to be paranoid about a finger prints. Dirty tubes can go to a dishwasher once a year. No - not the washing machine and don't try to spin them dry.

11. The life expectancy of the tube given in hours is in fact 10 to 20 x bigger than declared on the document. Usually it is a ridiculously low 2000 hrs. They give this value for working under ABSOLUTELY MAXIMUM, worst conditions. : maximum current, maximum voltage, maximum power, maximum temperature, any worst case scenario, add to it a safety design marhgin - 25% civil engineering headroom or 100% military headroom, They assume "Sue me if you want" conditions. Using the same strict conditions, a passenger car would be guaranteed for a week.

In practical life in a DAC, all tubes should last a lifetime. 2000 Hrs is a sick joke.

And lastly - the world has accumulated the supply of tubes that can keep our industry going for another 600-800 years even without new production.

1. Never trust internet opinions, because every circuit is different and every operating point is different, hence there is no defined specific tube sound and disappointment can be lurking on the horizon. By far the best way to save huge money losses is to borrow before buying. Trying in YOUR SYSTEM not in your friend's system.

2. Listen to your equipment manufacturer advices. We for example have 40 different tube types to try and when we choose one - it is because it sounds best. Anybody as a hobbyist, privately - cant try so many tubes and what do you do with the "not selected" ones afterwards ?

3. used tubes of DHT type should be forbidden from shipping. Their cathode is a thin tungsten or other metal string, which gets VERY fragile with hours of usage. So a tube may be 50 years old, of which 20 years it was used, their guts are more fragile than faberge egg. So if you get this 1000$ tube and it crackles - the seller will say SORRY - it was perfect when I shipped it. New tubes can be shipped safely, but not old.

4. "Brands" do not guarantee any consistency. Similar tubes have been made by any plant for many different brands, also companies helped each other and made for each other complementary portfolio positions, for example Haarlan plant made the legendary ECC182 for Valvo, Philips, Siemens, Mullard, Amperex and probably some other as well. There is no such thing as a Philips sounding better than valvo. Also easch plant buys materials from many sources, and one metal is not the same as another metal, so especially across the plants and across the time - tubes hugely varied.

5. The so called getters are not getters, they are getter generators. What people refer to as getters - do not play any role, do not play any music, do not influence the sound, dont have any influence on anything whatsoever. It may however make some sens if a different tube tybe has a different shape of "getter" that may indicate overall assembly difference and it may mean a diferent sound. Thats how we can interpret saying like: the 6SN7 with D shape getter sounds better than the one with O getter. For the record: a getter is the silver shiny mirror stuff on the glass - a deposit of ions.

6. If you have say a Lampizator DAC and you buy a super precious set of DHT tubes, what you do is called sometimes "tube training" or "regeneration". You wanna gently bring to life a tube that maybe spend 30 years doing nothing. To collect all unwanted gasses and put them on the getters and not enjoy fireworks - you first do heating session without power applied to anode. You do this: first, remove the rectifier tube from the amp or DAC to "remove" high voltage component of the anode supply. This way the music tubes will be fed with heater only. Then set the DAC heater switch to the lowest current available (the furthest from 300B which is always the highest). (I mean even if it is actually a 300B use the lowest "wrong" setting). Instert the newly acquired unknown condition tubes. Keep them warm for 24 hrs. After that, if there is a "correct" setting for the new tubes thats not the one you used - we call it nominal - use that another 24 hrs. After the total of 48 hrs insert the rectifier tube (while DAC is ON) and let it warm up. Very slowly the new tubes will be given anode high voltage and will start conducting the current.

7. Remember, the current is flowing in the tube from bottom - up. From Cathode to anode - the whole magic of tube operation happens IN THE CATHODE , the electron generation and emission to the space around the wire, which in this case is the filiament - the tiny glowing string. That is your tube! Magic happens! The whole black box inside is just anode - almost unimportant. It only collects the electrons and sends them to the ground. So it doesnt matter if the tube has black anode, grey anode, shiny anode etc - the CATHODE is far far more important. But we practically can't see it, so nobody discusses it.

8. You can easily measure many tube and circuit parameters using only the simplest voltmeter from Home Depot. Having said that, every audiophile worth his salt MUST have a real meter. It only cost 50-80 Euro and it will last a lifetime. For example UNI-T UT70B is an example of an excellent high end but cheap meter. So once you have any meter, you can gently pull the tube up by 1 cm or 1/4 inch and gain access to the pins and there are MANY things you can measure: bias current, bias voltage, grid voltage, heater current, heater voltage, anode voltage, signal gain, cathode voltage, incoming signal strength, outgoing signal level, even to some degree - the output impedance. Just a meter and 10 minutes of work to do all that. No tools required.

9. You can swap rectifier tubes while listening - there is no pop, no click, and no damage to the tube, no damage to the equipment. Just use a glove.

10. it is ok to touch the tubes with your hand (when it is cold !) , no need to be paranoid about a finger prints. Dirty tubes can go to a dishwasher once a year. No - not the washing machine and don't try to spin them dry.

11. The life expectancy of the tube given in hours is in fact 10 to 20 x bigger than declared on the document. Usually it is a ridiculously low 2000 hrs. They give this value for working under ABSOLUTELY MAXIMUM, worst conditions. : maximum current, maximum voltage, maximum power, maximum temperature, any worst case scenario, add to it a safety design marhgin - 25% civil engineering headroom or 100% military headroom, They assume "Sue me if you want" conditions. Using the same strict conditions, a passenger car would be guaranteed for a week.

In practical life in a DAC, all tubes should last a lifetime. 2000 Hrs is a sick joke.

And lastly - the world has accumulated the supply of tubes that can keep our industry going for another 600-800 years even without new production.

Last edited:

This one caught my eye...

9. You can swap rectifier tubes while listening - there is no pop, no click, and no damage to the tube, no damage to the equipment. Just use a glow.

I fully trust Lukasz but I still think I would be nervous to do this. Maybe I need to see a video of someone doing it!

9. You can swap rectifier tubes while listening - there is no pop, no click, and no damage to the tube, no damage to the equipment. Just use a glow.

I fully trust Lukasz but I still think I would be nervous to do this. Maybe I need to see a video of someone doing it!

Many does that and I’ve seen also other tube gear manufacturers doing exactly the same...with no issues...This one caught my eye...

9. You can swap rectifier tubes while listening - there is no pop, no click, and no damage to the tube, no damage to the equipment. Just use a glow.

I fully trust Lukasz but I still think I would be nervous to do this. Maybe I need to see a video of someone doing it!

Myself, i rather turn it off despite being present xyz times while nothing bad happened..

Many does that and I’ve seen also other tube gear manufacturers doing exactly the same...with no issues...

Myself, i rather turn it off despite being present xyz times while nothing bad happened..

Does the DAC continue to work without the rectifier or is there a pause in the data stream?

Actually it works normally for like 10/15sec and than gradually sound fades out..Do the DAC continue to work without the rectifier or is there a pause in the data stream?

BTW I have bought a few tens of NOS valves from all over the world dating from 1910 onwards. I haven't ever had a problem apart from a 1940s Amperex 211 which the sender claimed worked before he sent it.

He refunded me.

I certainly have never done what Lucasz has described. Sure no harm in being careful but there is harm in being paranoid. Don't let it put you off too much is what I am saying.

He refunded me.

I certainly have never done what Lucasz has described. Sure no harm in being careful but there is harm in being paranoid. Don't let it put you off too much is what I am saying.

Last edited:

Thinking more about this.

I have found failure rates higher in new production valves to be perfectly honest and quite frank about it. Without any shadow of a doubt.

Just saying.

But that doesn't mean the failure was due to shipping. I think that was Lukasz's point.

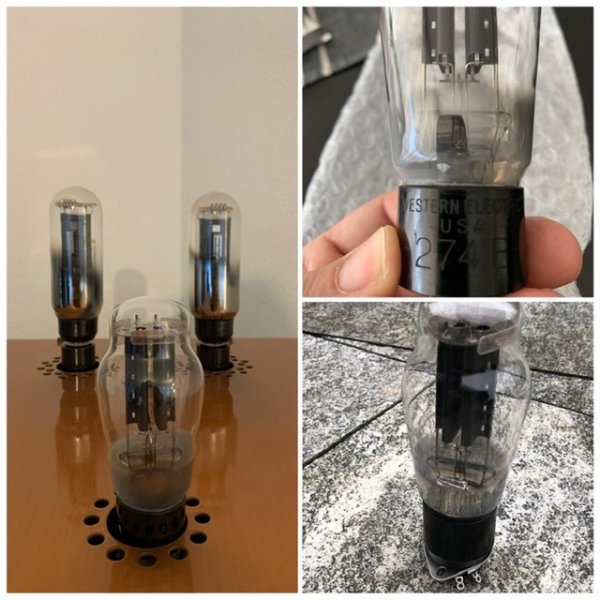

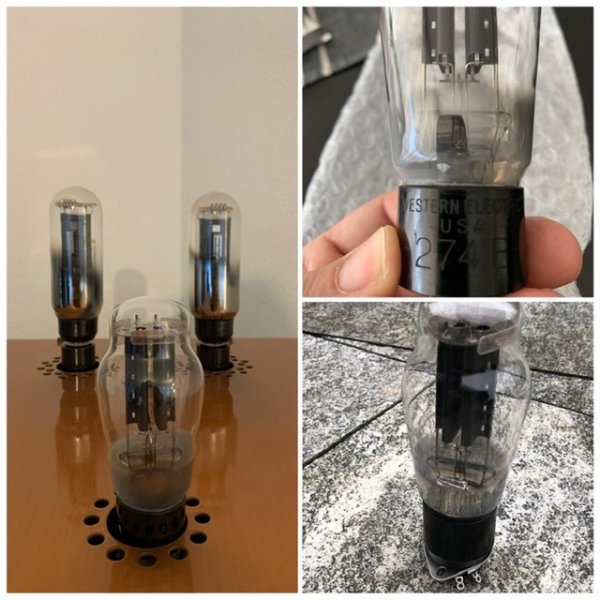

So what you do sitting at home for weeks and you get bored? Well having great friends who can provide some collector item tubes, you play with them. Few days ago i got engraved base WE274b and today i plugged it in instead of ACME to join RD27AS and things got even better - more resolution, even tighter LF, vocals are amazing, music is just filling the living room and overshadowing screaming of the kids  . totally love it....or I’m halucinating...no not really...phenomenal combo which i won’t use daily as this WE is just to preciouss...my preciousssssssss...i hate this f. virus btw

. totally love it....or I’m halucinating...no not really...phenomenal combo which i won’t use daily as this WE is just to preciouss...my preciousssssssss...i hate this f. virus btw

But that doesn't mean the failure was due to shipping. I think that was Lukasz's point.

No he said old tubes shouldn't be shipped as the filaments become fragile.

I haven't found that to be the case in decades. New valves fail because they just don't make them like they used to.

I had a few of JJ EL84s fail on me out of 12 bought brand new. Had to by four more. And 12 Golden Dragon EL84s - 10 died within 3 months.

The phenomenal sounding Tesla KT88 new production now EAT - three failed from a quad within months. All older Teslas of all sorts have been fine and I have had many.

A TJ 2A3 expired before it's time.

Look at the woes people have had with ELROG before the change of ownership.

I had to send back my RK300Bs due to a production flaw.

Etcetera, etcetera, etcetera.

The truth is they just don't make them like they used to.

no idea yet if ad1n has more gain than ad1 or 4883.Thanks for this info. I need a little bit of clarification? Are you suggesting the AD1n will have more gain @ 2 amp than the AD1 @ 1 amp?

@User211 You have only tried the AD1n, right? Or was it the AD1? Have you compared it, gain-wise, to any 300B?

NOS recti trio to play with: WE274b, WE422A, Marconi U52 (Das boot)..

View attachment 63536

Great stuff. Way to stick it to a pandemic!

Didn't know Westinghouse made a 422A. Is it the same as the Western Electric, just rebranded? I've seen them for sale but thought they were different.

NOS recti trio to play with: WE274b, WE422A, Marconi U52 (Das boot)..

View attachment 63536

You've got a great collection massing up Goran.

You've got a great collection massing up Goran.

Have a chance to get a U52. Very interested in this one

Got KR242's on the way too Goran, thanks to your help with all the reviews !

Similar threads

- Replies

- 5

- Views

- 676

- Replies

- 16

- Views

- 2K

- Replies

- 10

- Views

- 2K

- Replies

- 10

- Views

- 2K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |