From my experience, the differences between A80RC and A80RC mkII are:

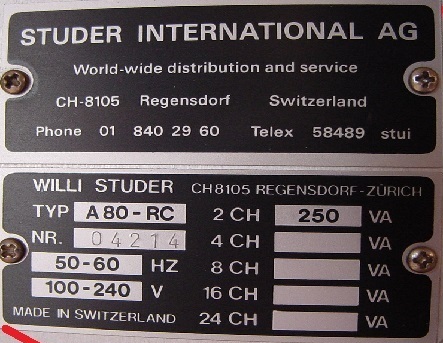

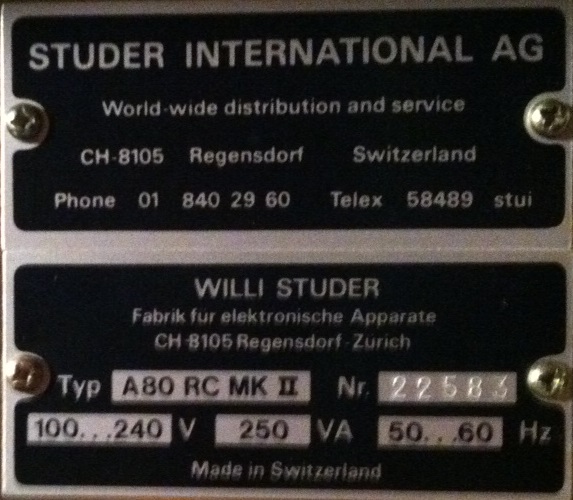

1) Label in the back of the machine with serial number

2) Generally speaking, earlier A80RCs (or MkI as referred by others) have speeds 7.5/15 ips whereas MkIIs have 15/30 ips (but not absolute info since it can be converted to one from the other)

3) There are many transport control and audio card revision differences between the two. If the boards are all original, one can visually identify an old A80 transport cards by adjustment pots with round face metal casing and Mk IIs having square plastic kind. Again the board could have been replace (as found on Spooling Control card in the eBay machine that must have been replaced at one time). In the audio card racks, you can tell first by looking at the Oscillator card. A80RC has only one 1/8" DIN Erase current connection on the faceplate of the Oscillator card and most MkII has additional four yellow LEDs for various status indications (could vary widely with different configurations - stereo/mono, etc). Of course there are major differences in audio cards and audio power supply boards. As I had mentioned elsewhere, there are two different discrete audio "opamp" modules and beefier audio power supply found in Mk II.

4) Another visual indication of a machine's age is coloration of the PushButton legend color. Although it can be easily replaced but as shown in the eBay machine in discussion, the PB assembly seems to be original and shows its serious age with deep yellowed discoloration. Younger PB label has white color. More significant difference in the PB assembly is in its non contact solid-state switch used in Mk II version and old regular contact type used in earlier A80s. Of course the non-contact type will last longer but could fail being an active part.

5) VU meter assemblies for A80 and A80MkII are the same in both physical and electrical design other than the aged VU meters would have the +3dB red section faded into more like pink in color. One can look at the condition of the volume numbers around the monitor amp volume knob...for age.

6) Headblock and heads are another can-of-worms that are meant to be replaced. But remember if the head wear (anything more than ~1/8" in width flat surface, IMO) is too deep (such as the one from eBay), it can't be relapped but must be replaced. If the headblock cover has too many razor cut marks, it generally represents machine that wasn't loved in proper ways.

7) Capstan - brand new capstan or one that was reconditioned have mat finish with same color all through out the shaft. I personally don't think mirror finish from normal use isn't all that bad as long as it pulls the tape properly. The Nagra T's have its entire capstan in mirror finish including tape contact area. On the other hand, if the wear is too deep to be felt when one runs finger nail across, it can't be good.

8) Runtime meter - its main use is to estimate the head use hours (IMO) and can't be the ultimate indicator of the machine's actual age. It can be disconnected, even wired in reverse to get younger as it gets more use (as recommended by Sony for their APR5000 series machines) and could run completely over and reset (more than likely what had happened to eBay machine)

9) other than the 1/2" head shield has no marker, there's no differences visually between 1/4" and 1/2" machines. However, there are electrical differences in both record and repro EQ boards.

In short, visual inspection of a Studer A80 is a small indication of the machine's actual operational condition. One never knows until the machine actually goes through exercise of basic operational tests with tape loaded and running of a cal tape for audio performance test. I personally prefer an old A80 that had been well taken care of in a recording studio than a newer A80mkII that had been neglected in a typical radio station. Checking how many tries it takes to Return to Zero after FF or REW, smooth Stop/Play transitions and FF/REW then going immediately to Play mode without creating tape loops around the capstan are good basic tests for proper tape transport operation. This could be a good subject for another post.

Ki