Stellavox SM8 Service by Jean Michel

- Thread starter Amir

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OK,

The "Mickey Mouse Ears" ABR is as good of a "solution" as you could expect considering the company's financial and developmental resources.

If you look at the total number of SP/AMI/TD machines produced over its roughly 20 year life, multiply by the prices they actually got for their products and divide by 20, you won't get a very large number. Then look at their overhead; this wasn't a large business by any means.

I'm amazed at the precision / construction / build quality of their machines. Ingenious take on constant tape tension. All of which with simplest, practical "solutions". Believe they only had one machinist. Quality of the individual mechanical parts is simply amazing.

The ABR "works". Forget anything about a tight wind. Re wind / rewind the tape on your home machine after using - but for location work the Sp can do the job.

The Sp's used mostly 5/6 pin DIN (European standard) connectors - 7's had "twist lock" securing; 8's went to a "screw-in" barrel. All are still available but you have to do some looking - I can supply some Mouser numbers for the "screw in" types. Microphone inputs were originally DIN, but they went to "standard" 3-pin XLR's later on. All the SP machines (except for very few four channel) were designed/built for 2 channels. When sold for mono use, they used internal "jumpers" as necessary. Unfortunately they had a few different methods of doing this and you have to figure out which method for a particular machine if trying to convert a mono machine to stereo.

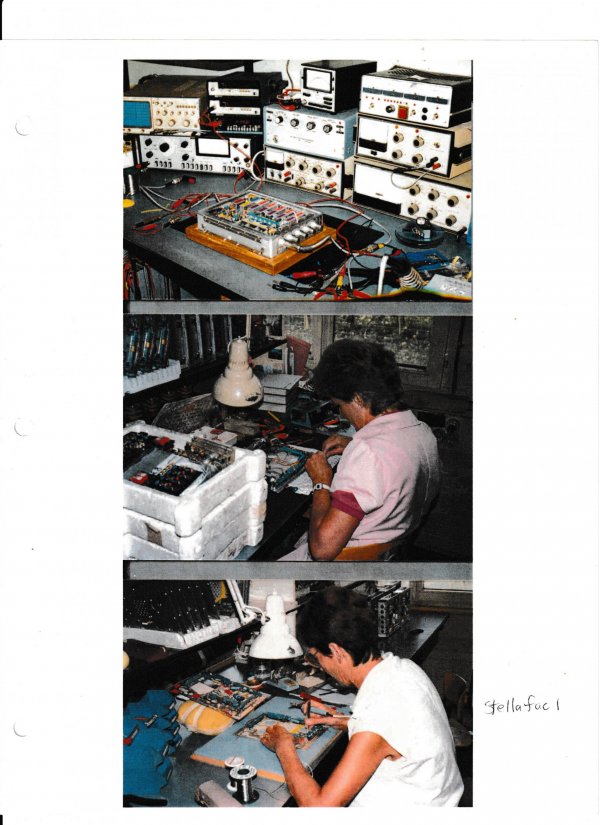

Because I have a bit of time, I''m "finally" doing a COMPLETE rebuild of a parts machine I got in trade. For any repair, I start by getting the transport going - down to bearing replacement if necessary. Determine this by holding/spinning the particular part next to my ear and LISTENING - motor also. Finished transport runs so quiet during play/record that you have to get your ear up to a few inches from the machine to hear anything mechanical. Doing a COMPLETE re-capping, which I've never done before, as getting to some of the caps is nearly impossible. See attached photo. Some caps are BETWEEN adjacent PC connectors. It's a 7 but since I have a "final" butterfly headblock, I'm going to make an "M" out of it. Upping the bias frequency will be the biggest challenge as there are no "M" bias assemblies left, and will have to "repurpose" a standard (SIZ) plug-in.

Most OEM parts are still available from Switzerland. Some NEW plug-in modules - at least the most -needed amplifiers are now available. Certain OEM machined parts are gone, but these don't break - if you're lucky.

Enough -bored you to death - Bye!

The "Mickey Mouse Ears" ABR is as good of a "solution" as you could expect considering the company's financial and developmental resources.

If you look at the total number of SP/AMI/TD machines produced over its roughly 20 year life, multiply by the prices they actually got for their products and divide by 20, you won't get a very large number. Then look at their overhead; this wasn't a large business by any means.

I'm amazed at the precision / construction / build quality of their machines. Ingenious take on constant tape tension. All of which with simplest, practical "solutions". Believe they only had one machinist. Quality of the individual mechanical parts is simply amazing.

The ABR "works". Forget anything about a tight wind. Re wind / rewind the tape on your home machine after using - but for location work the Sp can do the job.

The Sp's used mostly 5/6 pin DIN (European standard) connectors - 7's had "twist lock" securing; 8's went to a "screw-in" barrel. All are still available but you have to do some looking - I can supply some Mouser numbers for the "screw in" types. Microphone inputs were originally DIN, but they went to "standard" 3-pin XLR's later on. All the SP machines (except for very few four channel) were designed/built for 2 channels. When sold for mono use, they used internal "jumpers" as necessary. Unfortunately they had a few different methods of doing this and you have to figure out which method for a particular machine if trying to convert a mono machine to stereo.

Because I have a bit of time, I''m "finally" doing a COMPLETE rebuild of a parts machine I got in trade. For any repair, I start by getting the transport going - down to bearing replacement if necessary. Determine this by holding/spinning the particular part next to my ear and LISTENING - motor also. Finished transport runs so quiet during play/record that you have to get your ear up to a few inches from the machine to hear anything mechanical. Doing a COMPLETE re-capping, which I've never done before, as getting to some of the caps is nearly impossible. See attached photo. Some caps are BETWEEN adjacent PC connectors. It's a 7 but since I have a "final" butterfly headblock, I'm going to make an "M" out of it. Upping the bias frequency will be the biggest challenge as there are no "M" bias assemblies left, and will have to "repurpose" a standard (SIZ) plug-in.

Most OEM parts are still available from Switzerland. Some NEW plug-in modules - at least the most -needed amplifiers are now available. Certain OEM machined parts are gone, but these don't break - if you're lucky.

Enough -bored you to death - Bye!

Attachments

Last edited:

Here is the video of the tiny SP7 using 12" reels. As you can see, it manages just fine in Play mode. The bearing noise in the video was before Charles did his magic to it.

As you might know, some people used the Lyrec Fred as the large reel driver for Nagra's. Fred is an interesting machine and should work fine in that application - I have not tried that myself. Maybe someday I will try it.

Charles is right - the Stellavox is a work of art, and this is how I see mine. It is also amazing to watch it do 30ips.

As you might know, some people used the Lyrec Fred as the large reel driver for Nagra's. Fred is an interesting machine and should work fine in that application - I have not tried that myself. Maybe someday I will try it.

Charles is right - the Stellavox is a work of art, and this is how I see mine. It is also amazing to watch it do 30ips.

Thank you Charles for information , I really enjoyed , please do not stop.

Thank you Victor for fantastic video, I love it.

I shared it here :

instagram.com

instagram.com

Thank you Victor for fantastic video, I love it.

I shared it here :

Login • Instagram

Welcome back to Instagram. Sign in to check out what your friends, family & interests have been capturing & sharing around the world.

instagram.com

instagram.com

Foxbat,

From Schllin's Stellavox book, page 131, there were two versions of the AMC counter. The original AMC with a left-hand drive, and the AMC D with a right hand drive. Apparently the left-hand drive "occasionally slowed down the tape.

And "at 15ips tape speed the meter reading corresponded to the exact number of seconds the tape was running".

From Schllin's Stellavox book, page 131, there were two versions of the AMC counter. The original AMC with a left-hand drive, and the AMC D with a right hand drive. Apparently the left-hand drive "occasionally slowed down the tape.

And "at 15ips tape speed the meter reading corresponded to the exact number of seconds the tape was running".

Thank you Charles, I knew I could count on you!  Is the counter only usable with the ABR's, or it also works with 5" reels? Also, does it fit under the cover?

Is the counter only usable with the ABR's, or it also works with 5" reels? Also, does it fit under the cover?

I am debating with myself whether to give my SP7 this $500 fashion accessory. it looks like the answers to both questions is a NO.

it looks like the answers to both questions is a NO.

I am debating with myself whether to give my SP7 this $500 fashion accessory.

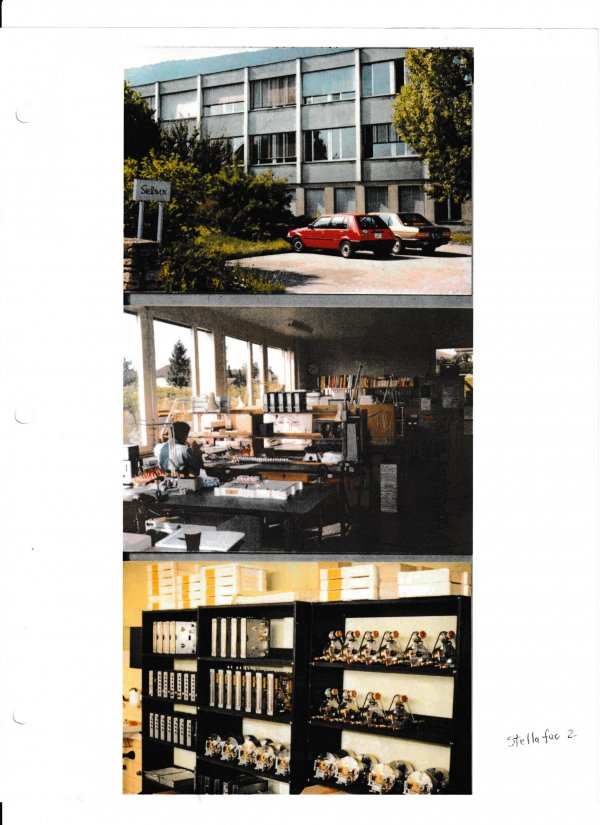

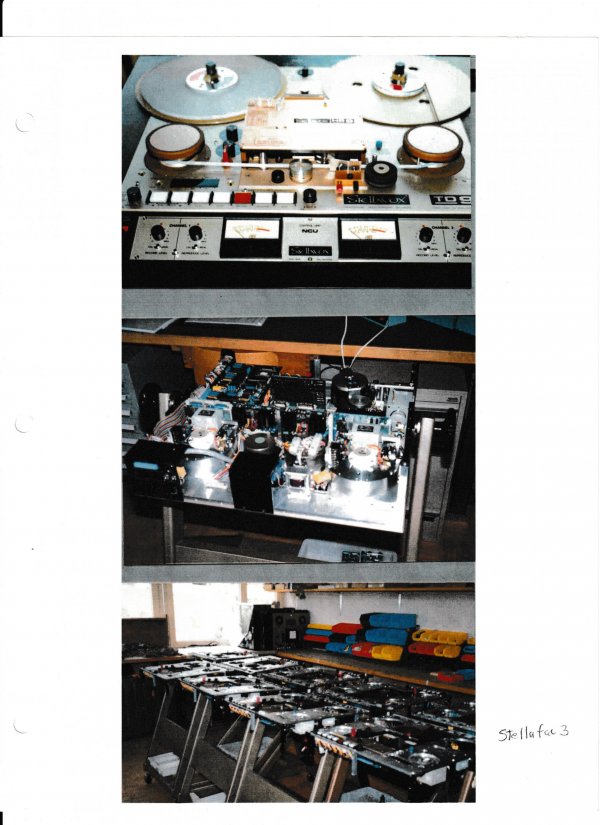

Here are some pictures of the Stellavox facility taken in the mid 1990's by Jim Stempke of Studio-Sonics (West of Chicago). At the time he was importing Stellas; took a trip to the factory to see how they were made and spent a few days watching them being built while picking up "tip" along the way. Got these from Jim when I bought his Stella spare parts and documentation. Sorry for the reduced quality - lost the original scans. BTW, Jim still services Studers.

ENJOY - and "eat your heart out"

ENJOY - and "eat your heart out"

Attachments

Last edited:

Hello friends,

I have a SP7. It is still not 100% ready: I am waiting for some cables. I have some questions:

1. Is the SP7 on par with the SP8 regarding sound quality?

2. Has anyone used them (SP8 or SP7) for audio mastering?

3. Does a Stellamaster headblock make a significant sonic difference? Has anybody compared it with the standard heads?

4. How do I connect XLR mics to my SP-7? Are there any adapter recommendations?

5. Which tape types are appropriate? Is there a type where we can say the machine is most likely calibrated to that type, as we can say for Nagra 4.2 and PER368?

6. Is Mr. Simonet still in business? I wrote to him, but I am still waiting for an answer.

Thanks!

I have a SP7. It is still not 100% ready: I am waiting for some cables. I have some questions:

1. Is the SP7 on par with the SP8 regarding sound quality?

2. Has anyone used them (SP8 or SP7) for audio mastering?

3. Does a Stellamaster headblock make a significant sonic difference? Has anybody compared it with the standard heads?

4. How do I connect XLR mics to my SP-7? Are there any adapter recommendations?

5. Which tape types are appropriate? Is there a type where we can say the machine is most likely calibrated to that type, as we can say for Nagra 4.2 and PER368?

6. Is Mr. Simonet still in business? I wrote to him, but I am still waiting for an answer.

Thanks!

Last edited:

Arseny.

Regarding "better sound between the 7/8: a few things. Stella changed heads over the course of production. Original 7's used Bogen PB and Record heads. Always used Wolke erase. Somewhere along the line they switched to Nortronics heads - first for PB and then record. Maybe a sourcing issue. Toward the end they may have gone to AM Belgium as I have a bought a set of Butterfly (Stellamaster?) heads from them that are NOT either Bog nor Nor. I happen to like the Bogen best - very well shielded against motor noise and to me they sound better. SO there is the issue of what heads happen to be on your machine. The 8 fit in two more AA cells and upped the audio voltage from 10 to 13 volts or so - little more headroom. Electronics between the 7 and 8 virtually unchanged.

Kostas did a LOT of recording on the S's. Don't know whom else may have also.

Regarding XLR microphone connections, Stella did put XLR's in place of the DIN mic connectors on SOME machines. Otherwise I usually make up a cable with two XLR connectors on one end and one DIN connector on the other end which can plug into the first deck connector from the front that actually can accept signals from both mikes.

Still working away on my refurbishment project - redoing all the audio cards. SPA/SOA modules really tough to find - apparently new ones are available but $$$. Replacing with IC's running from +/- 15V via a DC/DC converter - to get LOTS of headroom. Playback coming along nicely and sounding fine. Also will eliminate at least two, maybe 3 electrolytic caps per PB channel - same # for each record channel

Spare mechanical parts are becoming unavailable.

Regarding "better sound between the 7/8: a few things. Stella changed heads over the course of production. Original 7's used Bogen PB and Record heads. Always used Wolke erase. Somewhere along the line they switched to Nortronics heads - first for PB and then record. Maybe a sourcing issue. Toward the end they may have gone to AM Belgium as I have a bought a set of Butterfly (Stellamaster?) heads from them that are NOT either Bog nor Nor. I happen to like the Bogen best - very well shielded against motor noise and to me they sound better. SO there is the issue of what heads happen to be on your machine. The 8 fit in two more AA cells and upped the audio voltage from 10 to 13 volts or so - little more headroom. Electronics between the 7 and 8 virtually unchanged.

Kostas did a LOT of recording on the S's. Don't know whom else may have also.

Regarding XLR microphone connections, Stella did put XLR's in place of the DIN mic connectors on SOME machines. Otherwise I usually make up a cable with two XLR connectors on one end and one DIN connector on the other end which can plug into the first deck connector from the front that actually can accept signals from both mikes.

Still working away on my refurbishment project - redoing all the audio cards. SPA/SOA modules really tough to find - apparently new ones are available but $$$. Replacing with IC's running from +/- 15V via a DC/DC converter - to get LOTS of headroom. Playback coming along nicely and sounding fine. Also will eliminate at least two, maybe 3 electrolytic caps per PB channel - same # for each record channel

Spare mechanical parts are becoming unavailable.

Last edited:

Thanks for such an extensive and fast answer.Arseny.

Regarding "better sound between the 7/8: a few things. Stella changed heads over the course of production. Original 7's used Bogen PB and Record heads. Always used Wolke erase. Somewhere along the line they switched to Nortronics heads - first for PB and then record. Maybe a sourcing issue. Toward the end they may have gone to AM Belgium as I have a bought a set of Butterfly (Stellamaster?) heads from them that are NOT either Bog nor Nor. I happen to like the Bogen best - very well shielded against motor noise and to me they sound better. SO there is the issue of what heads happen to be on your machine. The 8 fit in two more AA cells and upped the audio voltage from 10 to 13 volts or so - little more headroom. Electronics between the 7 and 8 virtually unchanged.

Kostas did a LOT of recording on the S's. Don't know whom else may have also.

Regarding XLR microphone connections, Stella did put XLR's in place of the DIN mic connectors on SOME machines. Otherwise I usually make up a cable with two XLR connectors on one end and one DIN connector on the other end which can plug into the first deck connector from the front that actually can accept signals from both mikes.

Still working away on my refurbishment project - redoing all the audio cards. SPA/SOA modules really tough to find - apparently new ones are available but $$$. Replacing with IC's running from +/- 15V via a DC/DC converter - to get LOTS of headroom. Playback coming along nicely and sounding fine.

Spare mechanical parts are becoming unavailable.

My interpretation is that I don't have to worry about the sound quality if I have the original Bogen heads on my SP-7. That's what I don't know. Here's a photo.

I'll check the recordings of Kostas (Kostas Lazarides is a Greek-born American country music songwriter)

I'll create a DIN<->XLR cables. Is there some pinout that I should consider?

Redoing all the audio cards sound interesting! Where are you based?

Is there any tape you would recommend?

Thank you

Stellavox used Photovox heads, at least at one point. From the TAS review of the Metaxas Tourbillon:

www.theabsolutesound.com

“The heads themselves are the same type used in Stellavox’s TD9 machine—Photovox Butterfly units made in Torino, Italy.”

www.theabsolutesound.com

“The heads themselves are the same type used in Stellavox’s TD9 machine—Photovox Butterfly units made in Torino, Italy.”

Kostas Metaxas T-RX Tape Deck

I’m not going to kid you: I am among the mechanically inept—high among them, I would say. If there were a merit (or demerit) badge for hastiness,

Similar threads

- Replies

- 38

- Views

- 8K

- Replies

- 9

- Views

- 5K

- Replies

- 84

- Views

- 15K

- Replies

- 0

- Views

- 3K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |