Final post in my response to your thoughts...As requested by @J.R. Boisclair I copied my post down here from AM thread.

Even though there may be problems like test record quality, interface etc, I still believe that AM software is best for cartridge setup process. I consider visual methods like using a zenith protractor/tool, eyeballing are far more primitive compared to AM. There are too many variables, more precisely too many assumptions.

For example when you align zenith using a zenith tool you think that you’re all set as long as you’ve sent your cartridge before to Wally and you know it’s zenith error. But there are multi assumptions in this solution. Lets say your cartridge has 2.2 degrees zenith error reported by Wally.

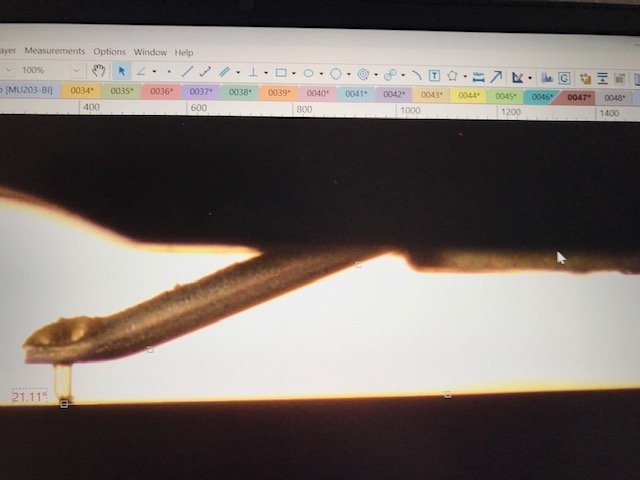

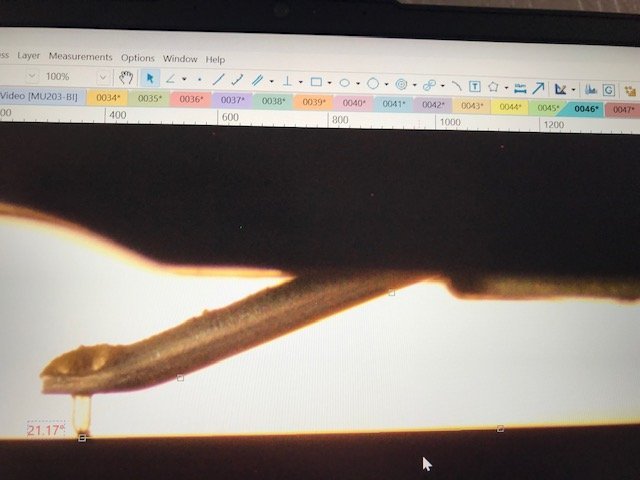

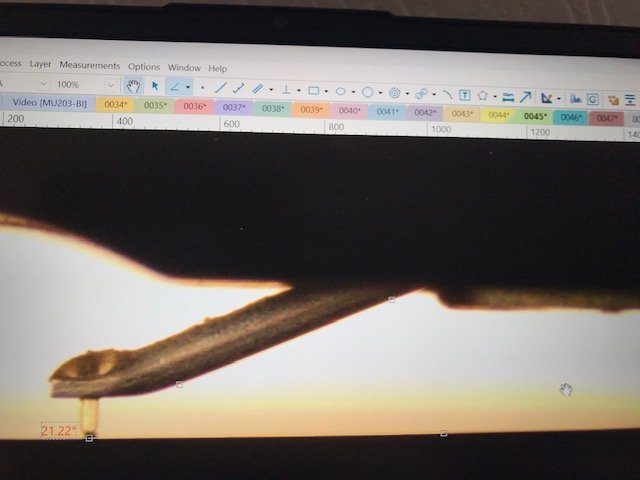

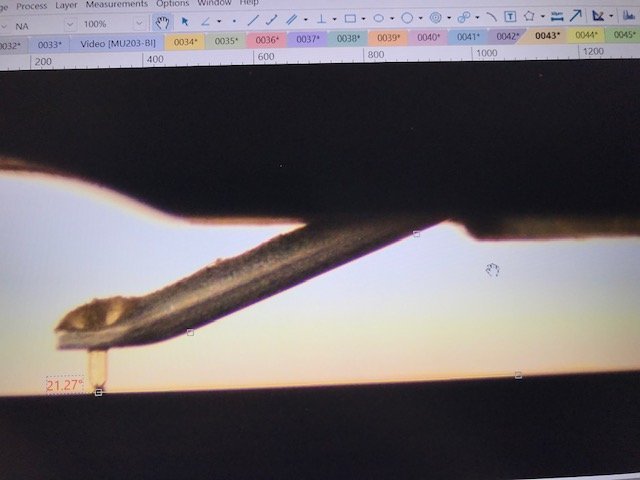

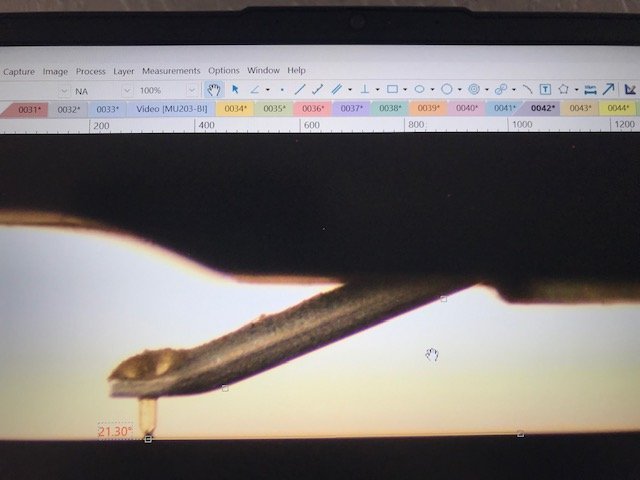

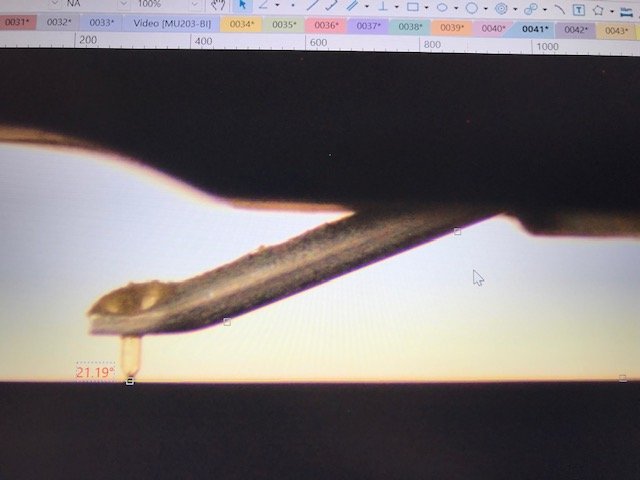

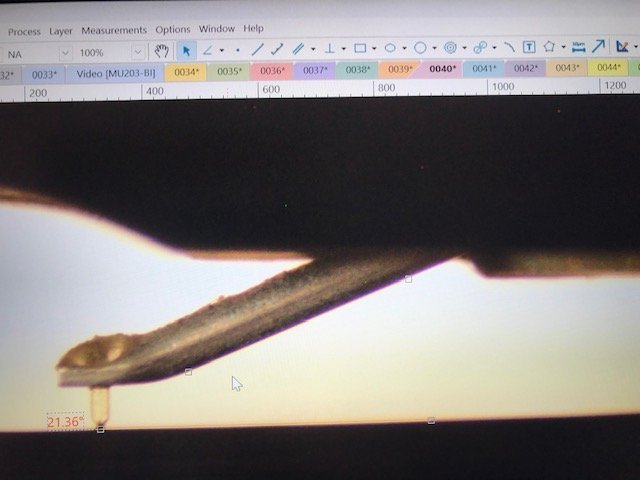

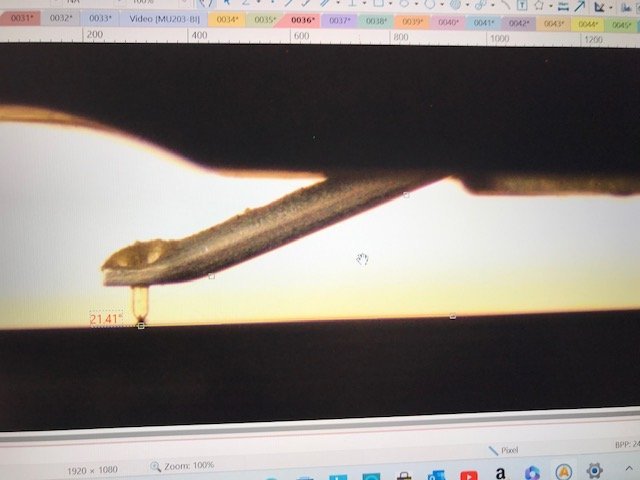

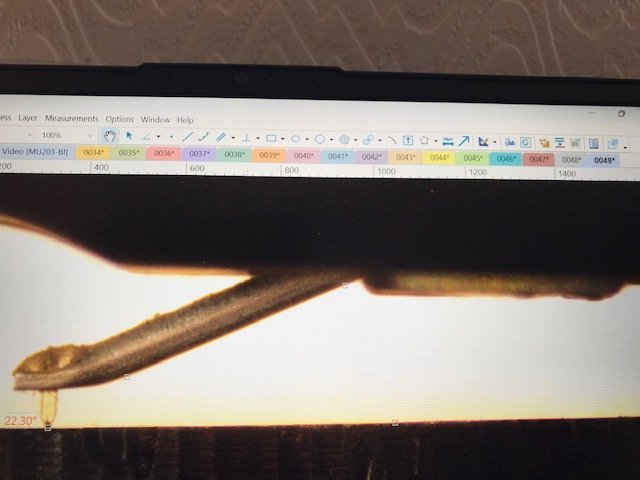

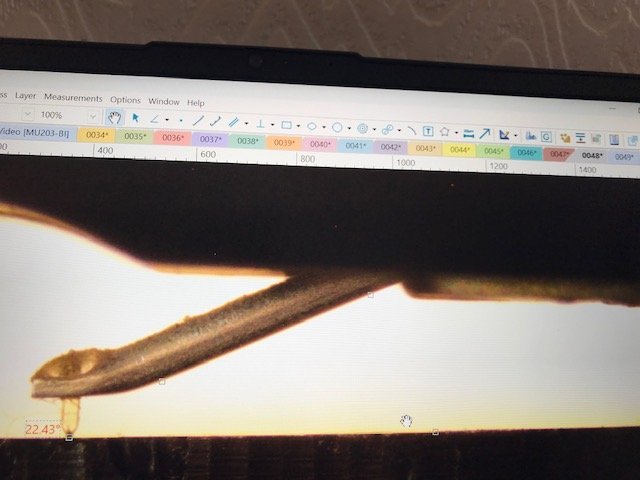

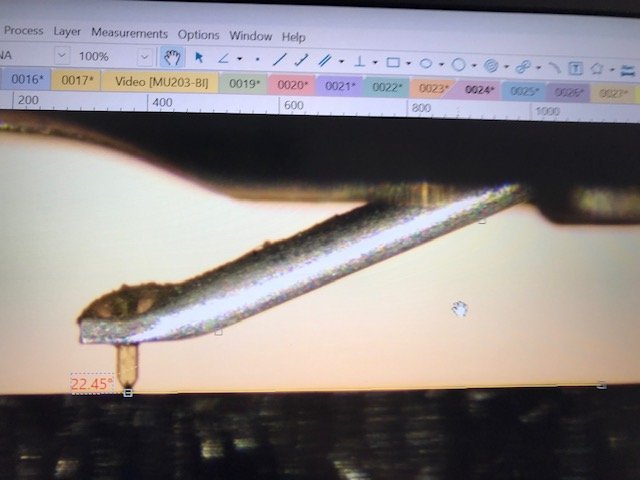

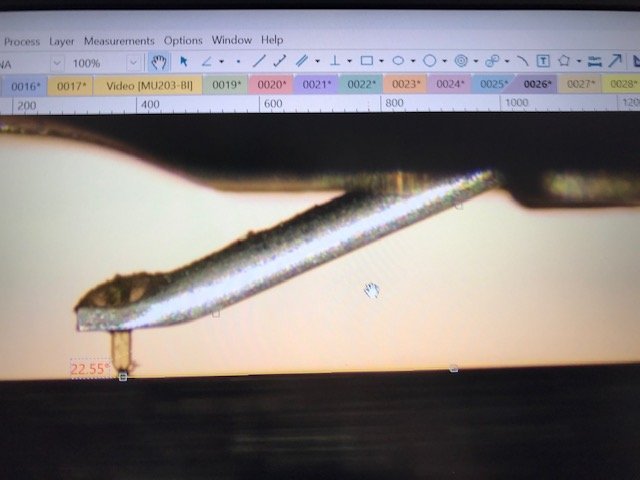

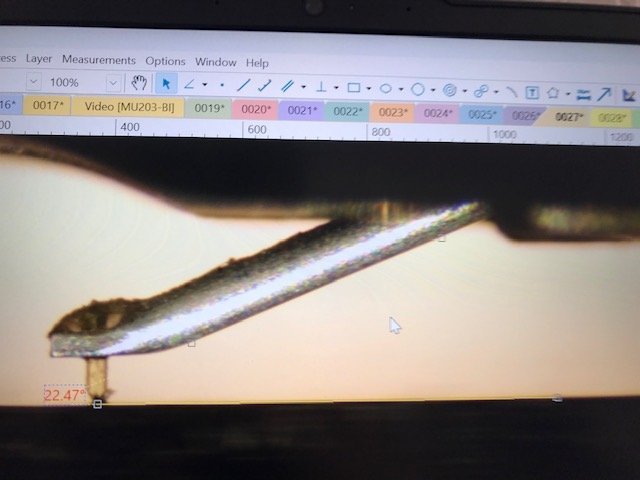

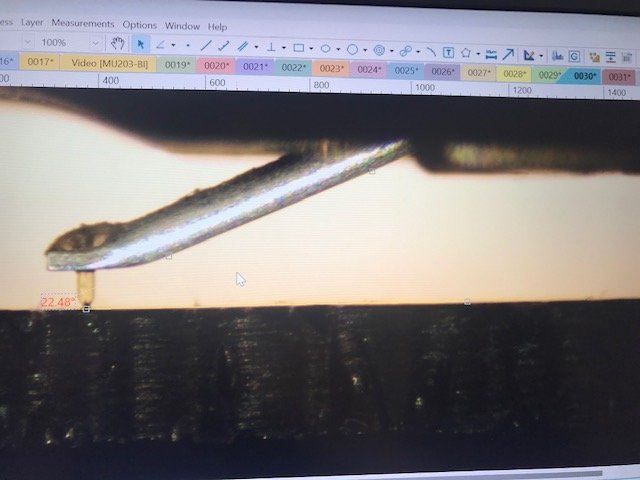

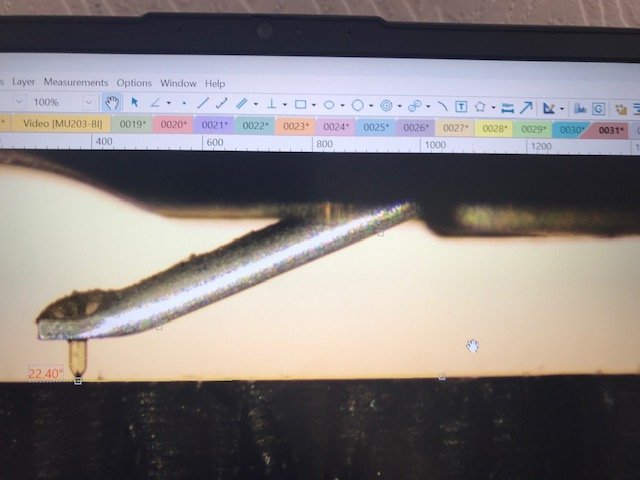

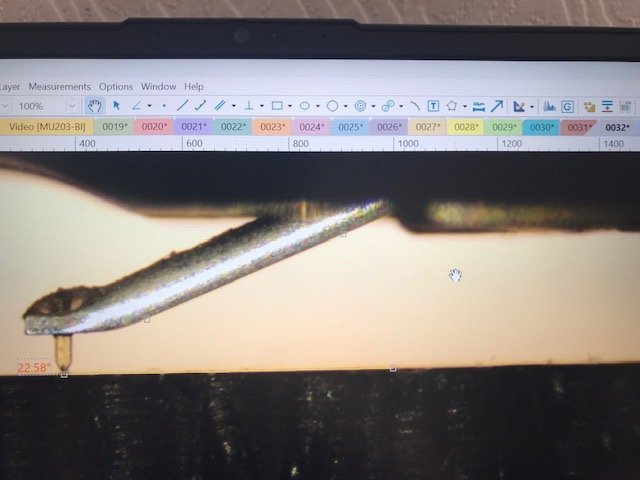

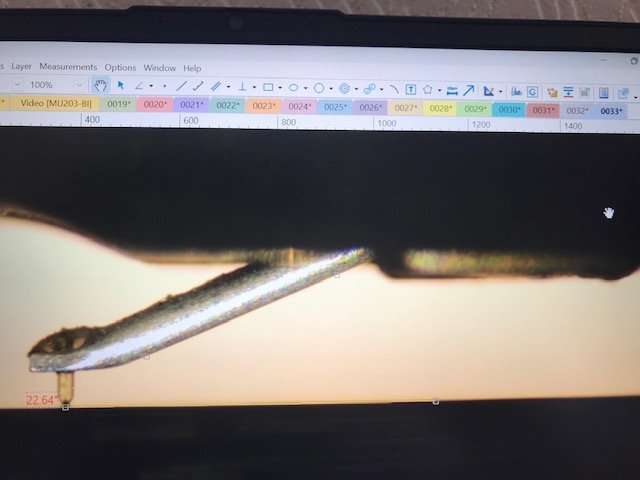

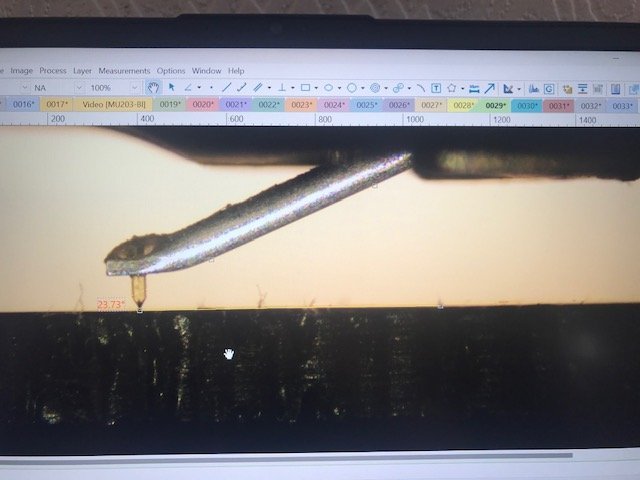

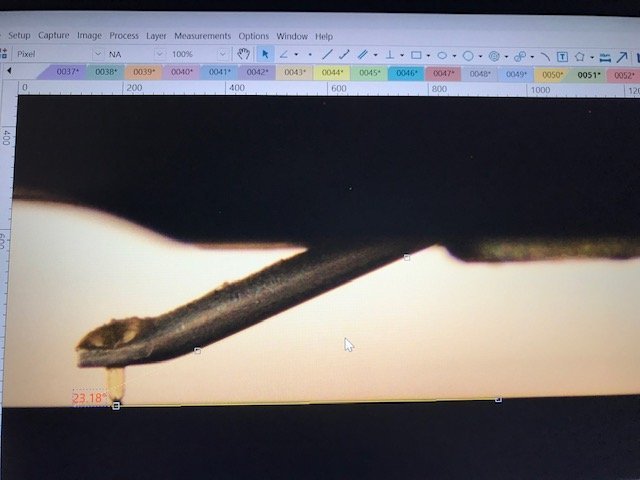

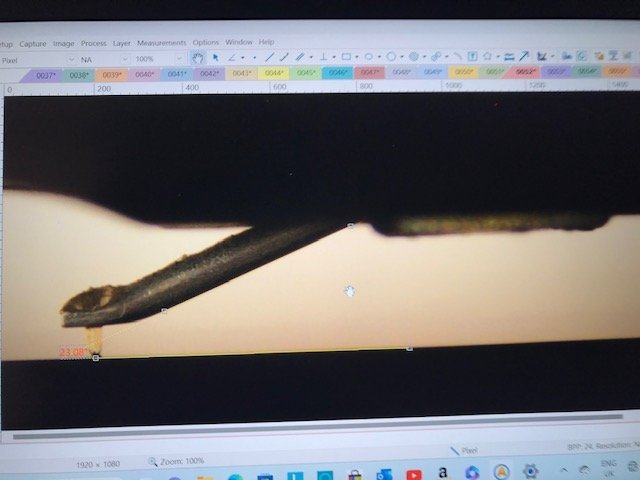

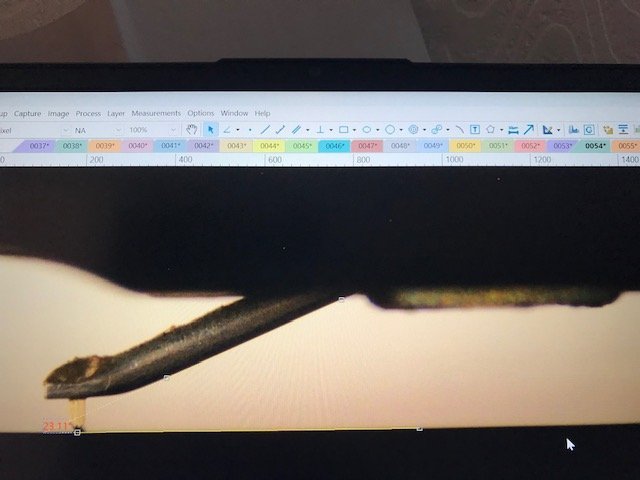

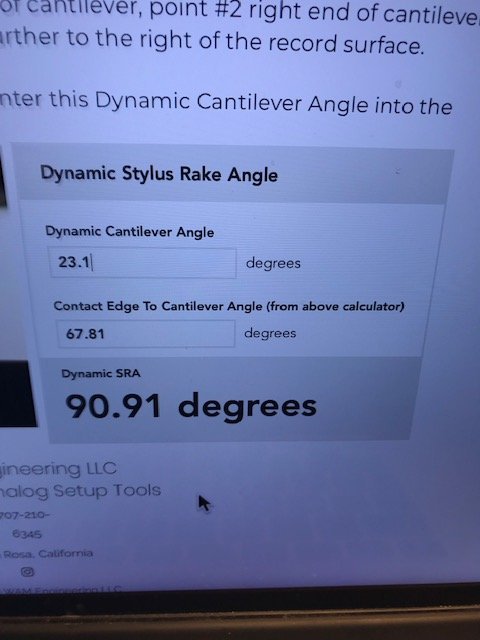

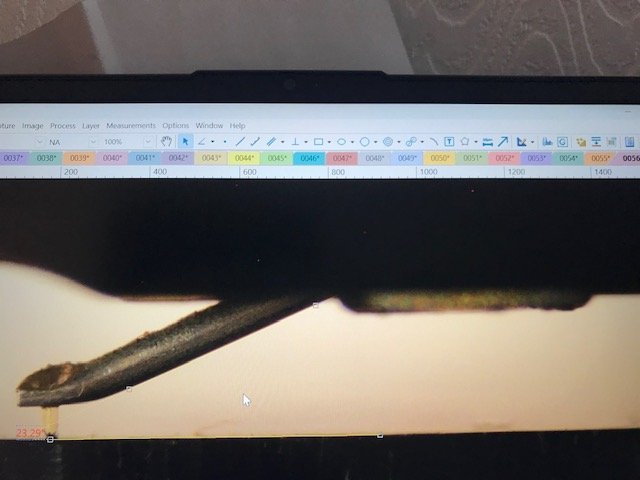

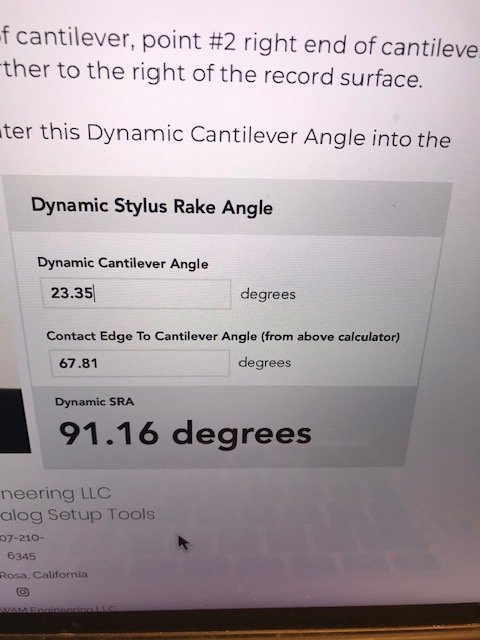

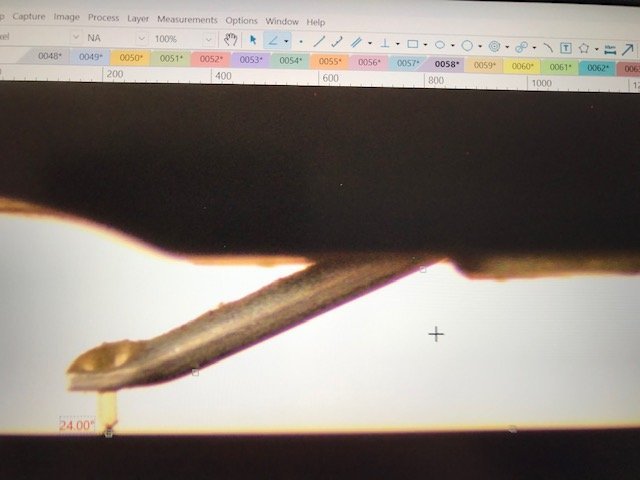

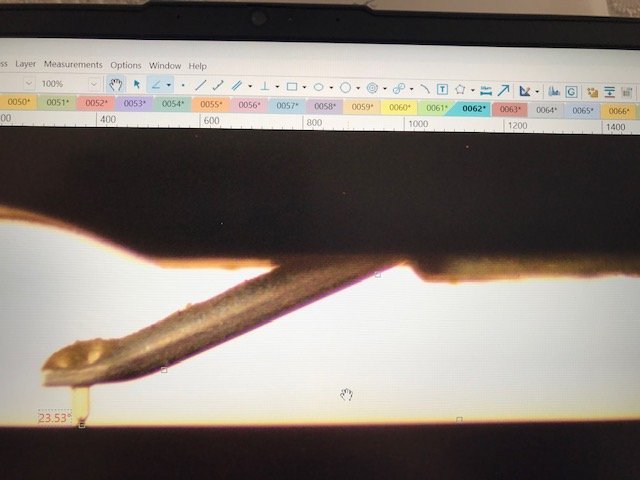

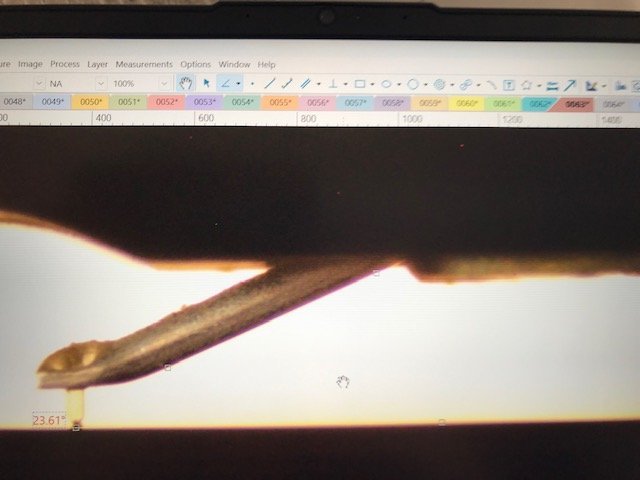

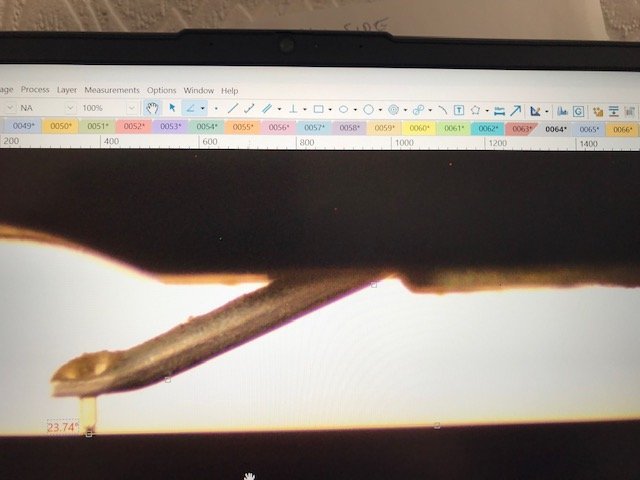

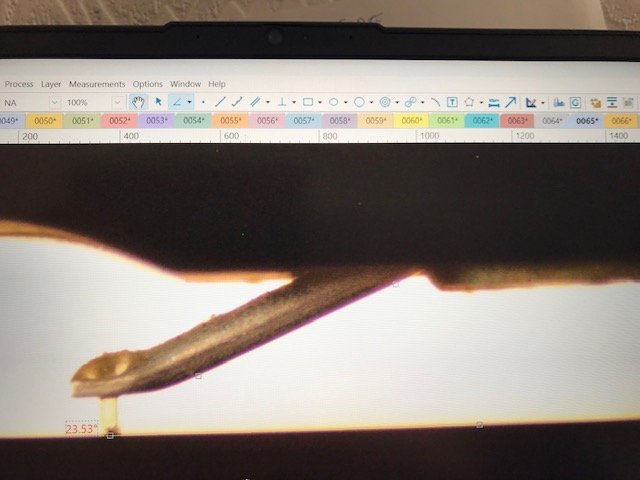

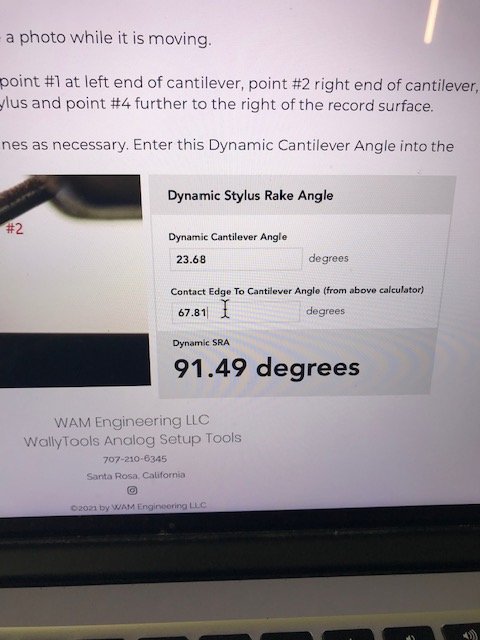

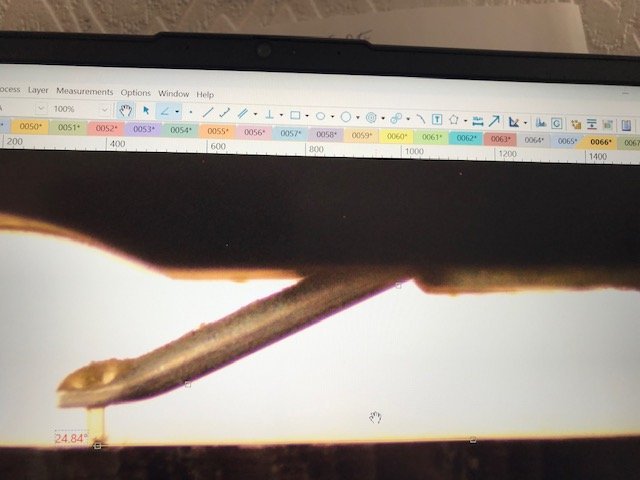

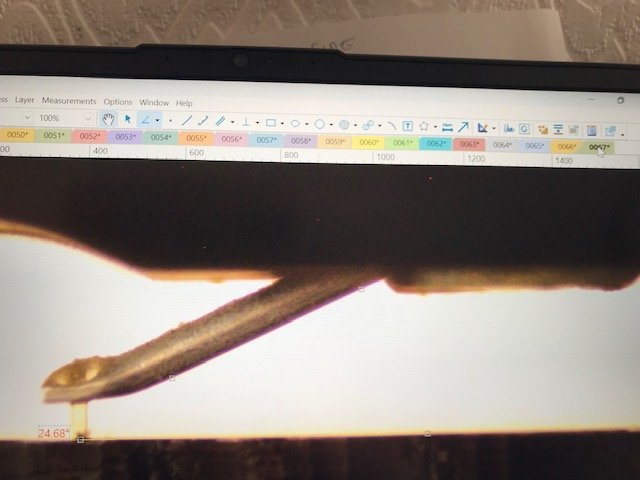

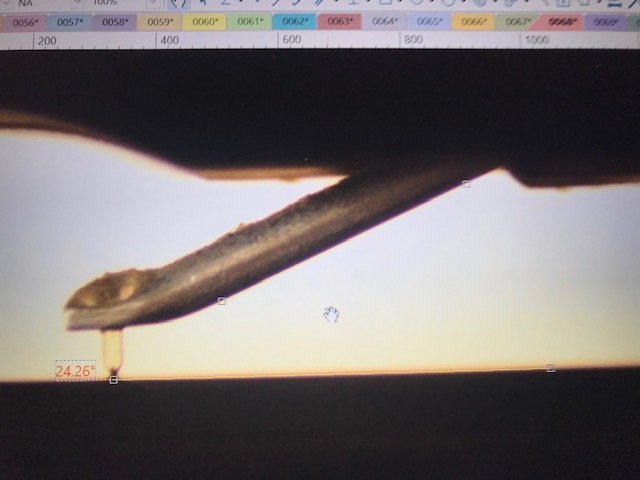

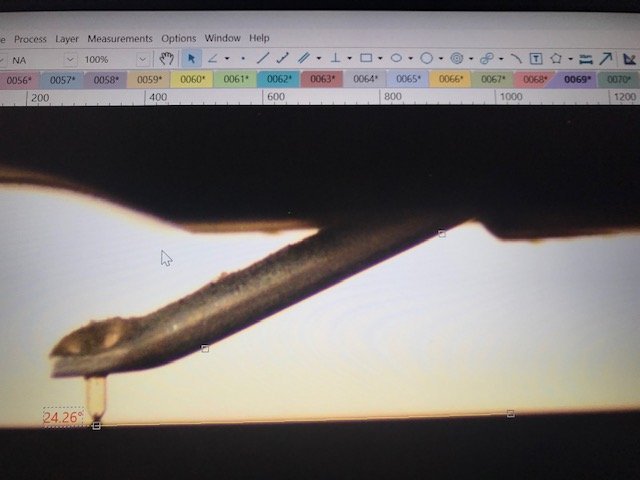

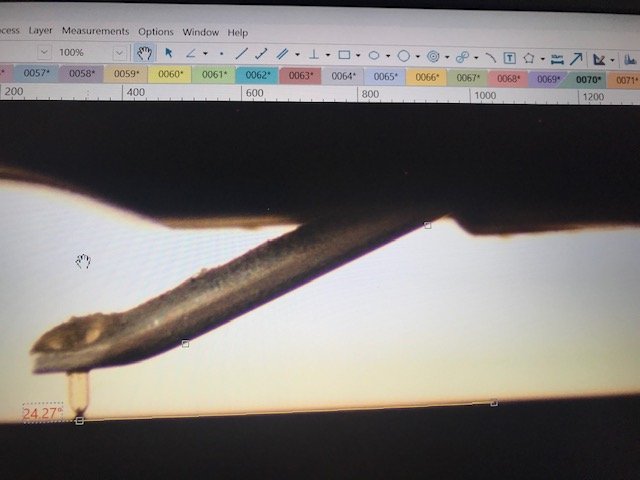

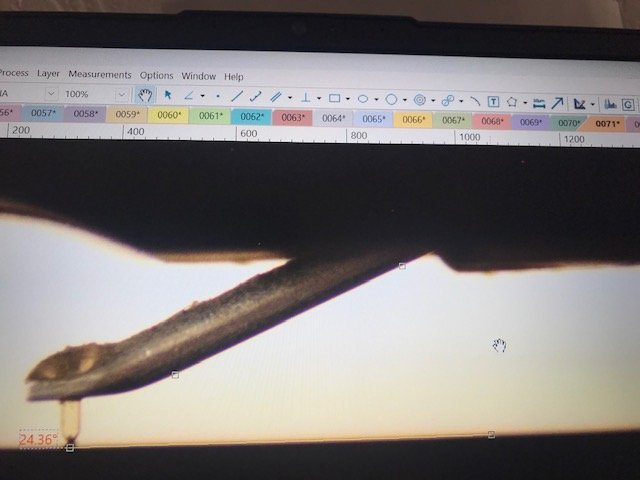

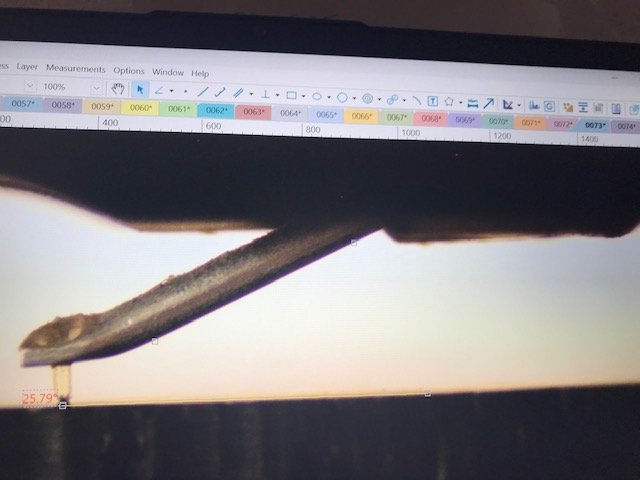

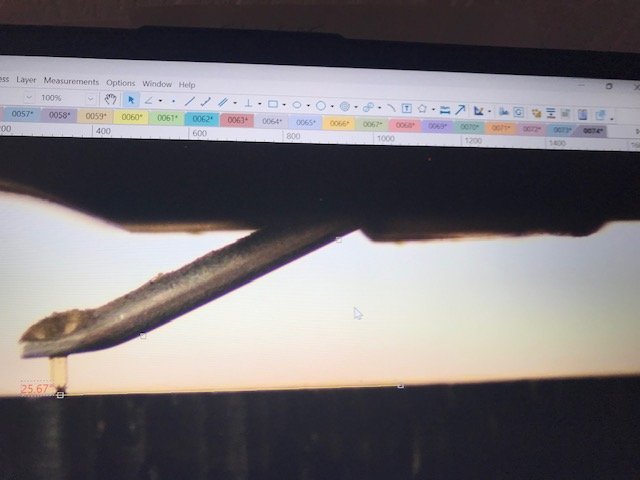

- First assumption is trusting that it’s measured precisely. Considering difficulties of measurements with microscope I wouldn't take it granted.

- When you try to correct it using zenith tool you need to align cantilever to 2 degree line which is very hard to do visually. No matter what people say it’s incredibly hard to align cantilever parallel to a line on a mirror surface. Thinking that you aligned cantilever exactly parallel to respective line is second assumption. Additionally you can not align 2.2 degrees as far as I know. Not a great deal but you have to choose 2 or 2.5 lines.

- Cantilever angle (zenith) changes according to anti-skating. If you use Wally skater you set anti-skating according to VTF. When you play a record depending on the stiffness of suspension (soft or hard) the cantilever may skew more or less so cantilever may not be parallel to the lines you set before. Expecting cantilever's skew to match anti-skating you set earlier is another assumption.

- One side of suspension can be softer which is very common even if suspension is in great condition. In that case cantilever's skew angle will be effected by soft side when playing a record. Again zenith will be different than visually set. More assumptions.

If everything is perfect those assumptions are ok but nothing is perfect. That's why arc protractors are great cause it gets rid of assumptions by showing the actual arc that should be drawn by stylus. It is simple, no assumptions. Other protractors like smartractor or Feickert rely on assumptions such as; you can perfectly land one end of protractor over the pivot point and perfect overhang will be set when you align stylus to land over the dot.

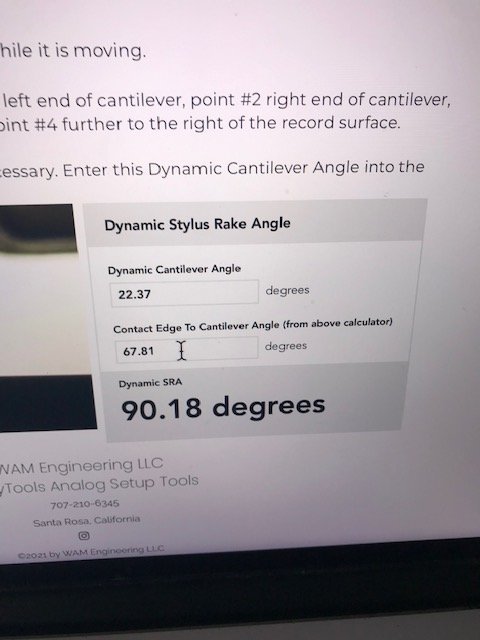

When you rely on static alignment procedures for a dynamic system based on pre conceptions like Wally solutions (except arc protractor), multi assumptions are inevitable. In this zenith example; when you accept overhang, VTA/SRA and azimuth are set perfectly in advance there are still problems with zenith which will arise when the record is played. On the other hand when you use AM with a test record you align it dynamically and all factors (VTA, azimuth, ati skating etc) are at play. You only need to know where to look and to learn what the numbers are telling. I set zenith using AM V1 test record and check with AP test record. Track locations are different and cut at different places but both lead you to same zenith alignment. Even with AM V2 test record at hand being low in quality, it still gives same zenith results with V1. That’s why I said “far fetched“ for Wally’s multi assumption zenith solution. Those are my humble opinions.

I agree with your point about “beam” protractors versus arc protractors but you can also add the problem of stacked tolerance error that beam protractors are subject to.?

Here is the biggest issue I have with measuring electronically for a mechanical transcription system (a.k.a., turntable): test records themselves.

It is obvious that recording engineers can have a misaligned cutterhead, misaligned cutting stylus, misaligned sled or even an asymmetric cutting stylus (we see plenty of those!). However, they are equally likely to err clockwise versus counterclockwise against their targets. Further, we KNOW those targets or their target ranges (“ranges” in the case of cutting stylus rake angle and vertical modulation angle). The whole WAM Engineering effort is aimed at getting our playback stylus and cantilever to hit those targets. If we have a test record to use as our fiducial to hit optimal targets we are implicitly trusting the recording engineer of that test record to have NAILED all of their targets and to have used a perfectly symmetrical cutting stylus. More variables!

So how do test records do in this regard?

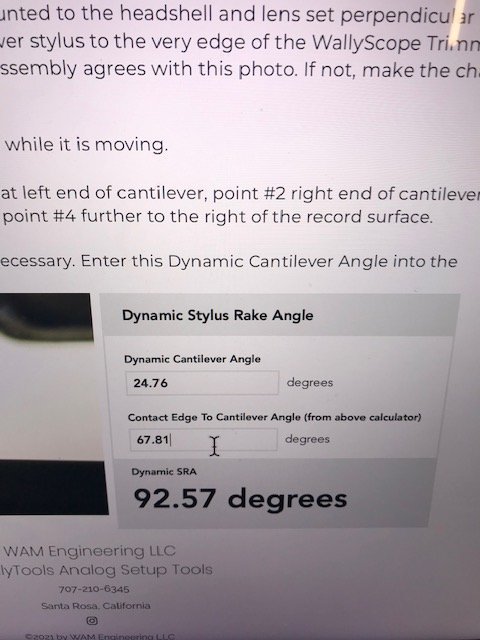

We have a growing stack of laboratory test records (now about 11” high) that we use for our tests but we leaned pretty quickly that the test records have errors of their own and we would need a way to measure those errors so we could net them out of our results so we could better run a worthwhile set of experiments. Since I could write a great deal on this subject I’ll limit it to CUTTING ZENITH ERROR and cut to the bottom line.

We have optically and electronically measured square and sine wave grooves in the vaunted DIN, NAB, CBS Labs, Denon, JVC, and more and found cutting zenith errors of as much as 4.25 degrees.

?So, if you are going to trust any given test record as your fiducial as true and accurate with regards to its fidelity to the engineer’s alignment goals, how do you know they have been attained? What procedures are written in the liner notes to assure you the engineers have taken all possible measures to do so and that they KNOW their own margin of error?

More variables. You also have to wonder about the algorithmic variables from software. We struggle with that frequently as we have seen that as we computationally filter and average data we can get variable results. We can even “force” the data to tell is what we want to see. Dangerous!

In our opinion, the proper way to make a test record is to communicate HOW we confirmed everything was dialed in perfectly so that you could trust the engineer and his work. The engineer should share his margin of error to demonstrate that all variables were properly managed.

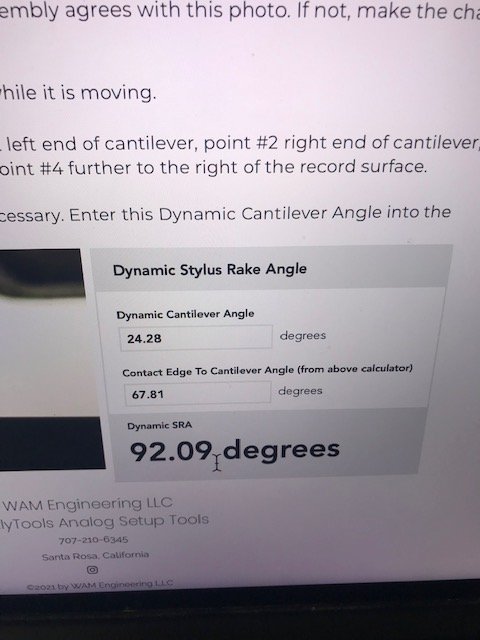

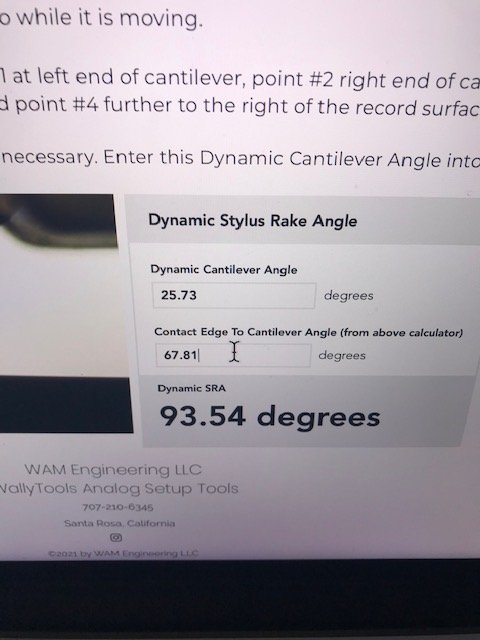

By the way, it is not possible to use the same track to optimize for SRA and VTA. SRA is most sensitive to horizontal modulations and VTA is sensitive to vertical modulations. They are both important for different reasons and though they cannot be adjusted independently, there is a balance to be struck. The research on this balance has never been done, much less published, as far as I can tell. In fact, though a great deal of work has been done on ideal VTA, next to nothing has been done on SRA. Generally speaking, cartridge manufacturers have WAY too high VTA (scientists and research engineers have been complaining about this since papers published in the early 60’s) so the lower, the better - particularly for some brands of cartridges. I think there has been a collective amnesia or willful ignorance amongst cartridge designers to fully understand the cost of a high VTA. The manufacturers enjoy benefits for kicking it high up. Audiophiles don’t. ?

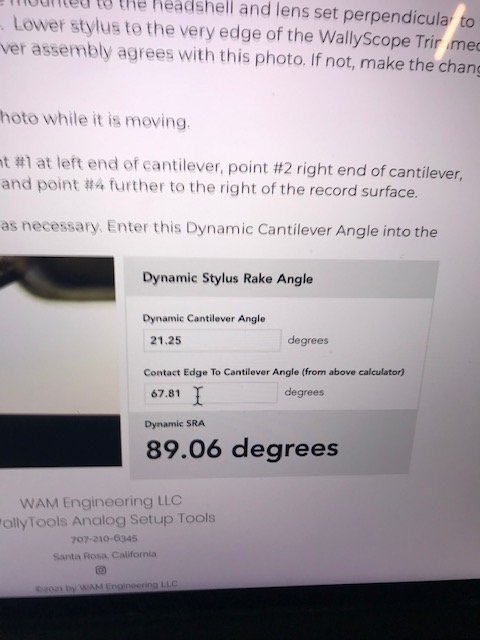

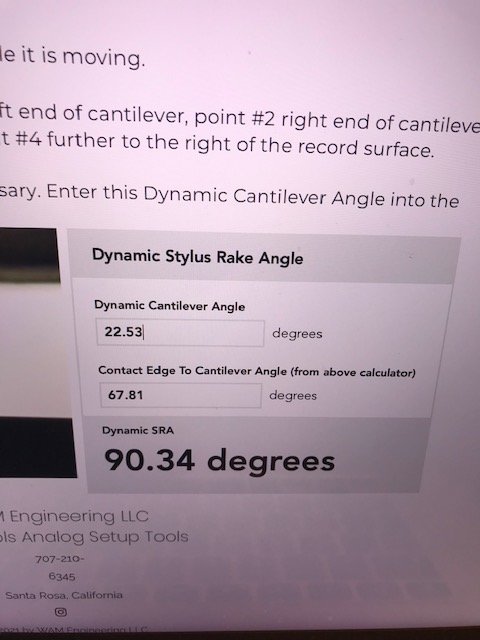

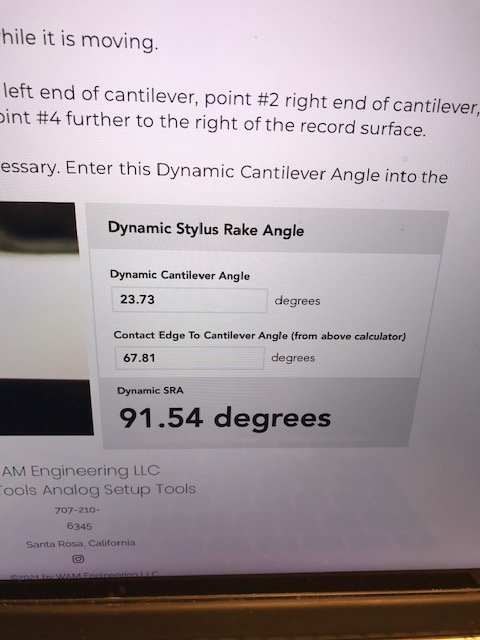

So, I hope I have made it clear that the WAM Engineering system takes into account DYNAMIC play for its alignment procedures and the variables which exist are known, measured and controlled for. One cannot say that about use of a test record as a basis for cartridge/ tonearm optimization for which the variables are not known or shared which allows us to infer that they are not controlled for.

If I did not address any of your points, please let me know. I certainly appreciate that you think deeply on these topics. Whether we agree with each other isn’t important. People like us push standards upwards and that benefits many.