Thank you for your detailed explanation of the physics involved in this context.

While your analysis is informative, I respectfully hold a different perspective on the stability of one tower tonearm vs. two tower that hold the tonearm (at list in theoretical manner)

You mention that increasing the number of points of contact may not improve stability, but this oversimplifies the issue. In practice, a higher number of points of contact can distribute forces more evenly and reduce the risk of vibrations or resonances that can adversely affect sound quality.

I believe that stability in this context is influenced by various factors beyond just leverage, including resonance damping, tracking accuracy, and how well multiple points of contact interact with the cartridge and the record.

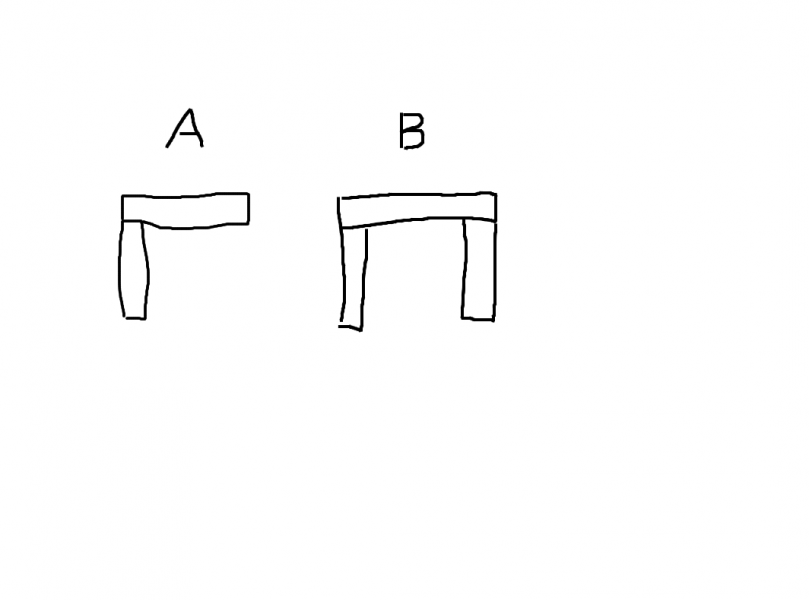

If we have two arms, A and B, with the same weight, and assuming both are well-constructed, wouldn't one of them theoretically exhibit greater stability and be less susceptible to the influence of gravity or resonance compared to the other?

No I think I understand your point.

you are stating that the cross beam being supported at either end is more stable than a cantilever design.

So to clarify in reality a cantilever is an overturning moment in affect. We achieve mechanical advantage over this moment quite easily, by increasing structure at holding down column. For there to be a pulling out force at the holding down assembly the forces needed to do so are incredible, even using the cantilever structure as a lever.

If we were expecting to distribute high loading on the arm then yes a ‘goal post’ configuration maybe a better solution, but that would be based on any spacial engineering constraints and geometry.

As the loading to cantilever advantage in most linear tracking arms that utilise a cantilever design is such a high ratio, unless the user is doing something abnormal to the operation of the arm, in normal operating conditions the performance or stability is not affected.

I however cannot speak to other manufacturers, I can only say that VYGER ratio is in the order of 1000s with zero deflection across the entire structure.

I do accept your point that supporting a load at both ends surely is the most stable way if the criteria is a high loading situation, typical to a universal beam used to support the removal of a wall in the home, this is again simple engineering with the loading triangle, but with a linear arm, the ratio even if the wand and bushing assembly is at the furthest point from the cantilever is so small that the threshold for deflection is nowhere close to being met, the structure remains very rigid.

So it then really moves onto what you feel is comfortable for you, regardless of the science, if you would prefer a system that was picked up at both ends, then you have options.

Regards

B