I acknowledge completely that there is no objectively "best" vibration isolation table top. What works well under one turntable in one system in one room may not work well in another situation. Every combination of turntable, room and preference is different.

There is no way to divine in advance, based on theory, what will actually sound best in one's system.

It would be great if I could have three or four different table tops of different materials and properties and weights to compare A versus B versus C in situ but that is not practical.

So I am narrowing the choices down to three different options by one company which will fabricate a custom table top.

This company specializes in steel and lead and every combination thereof. I am considering:

1) 3/8 steel (it can be cold rolled or hot rolled -- is one better than the other for vibration damping?) on the top and on the bottom with 1" of pure lead (sealed in urethane) and laminated together and then machined laboratory-grade flat as a complete sandwich (340 pounds)

2) Solid steel, 1" or 1.5" thick

3) A sandwich of multiple layers of 1/4" or 3/8" steel or lead or both in any combination

Are there any vibration engineering experts here who could tell me the theoretical pros and cons of each of these designs?

hey Ron,

Fascinating project! I find with really great technical advisors, this can be money very well spent. No marketing budget, allocation of significant overhead...just money spent on materials labor and margin for a specific project. And if the advisor makes his money doing larger commercial projects, then there can be often a lot less 'margin' padded in because it is audiophile. (kinda like the cost of flowers for a party...vs flowers for a wedding or a baby shower. Somehow the flowers for the latter always seem to cost 3x.)

One area i would look at is HRS and Von Schweikert...both use multiple layers of DIFFERENT materials in order to create isolation/vibration 'free' walls, structures. I do like HRS a lot, and i think Bergmann used to sell their top TT with an HRS designed table? Aluminum, granite, steel and elastomer material combined in layers.

In my own personal experiments with no manufacturing capabilities, i have found that steel/granite alone are not for me. I like some level of elastomer with it...but I like the steel/aluminum with elastomer...plus a LOT of sheer, dead weight.

As a result, i use a fair amount of HRS...and I also have combined all of my Stillpoints Ultra 5 with an HRS Nimbus Coupler (elastomer encased in aluminum) on top, and all of my Artesania dampers (some form of elastomer-like surface with steel) with a TON of sheer weight (200lbs) in the form of solid brass or steel on top. Interestingly, since both of these 'homemade combinations', I have noted that both companies have started selling properly manufactured versions that seem similar: Artesania now sells a damping plate in Asia with what appears to be 10kg of dead weight on top, and HRS now sells an aluminum cylinder with spike...that has an elastomer on top.

I am no techie, but just some food for thought as you design your custom table.

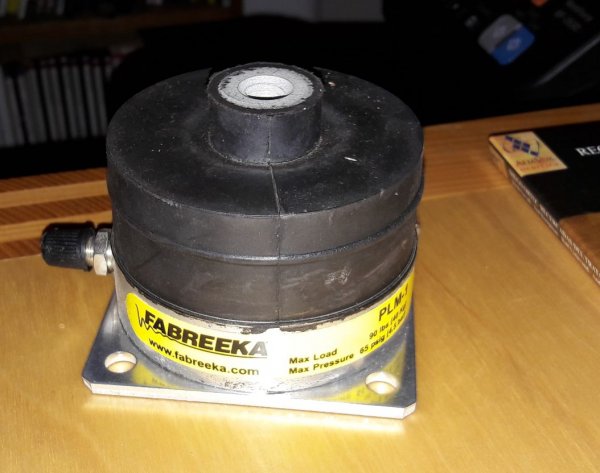

![20170101_082623[1].jpg 20170101_082623[1].jpg](https://www.whatsbestforum.com/data/attachments/22/22913-214c642305207bb3e7eea4056232a3c3.jpg)

![20170101_082637[1].jpg 20170101_082637[1].jpg](https://www.whatsbestforum.com/data/attachments/22/22914-589e60afbcfd8b3273f7c84d9f8daf8a.jpg)