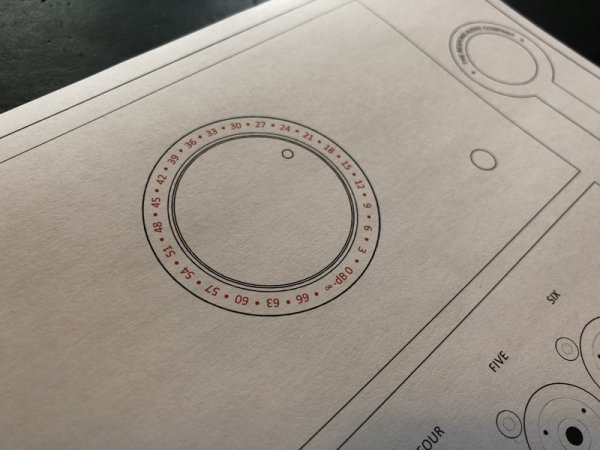

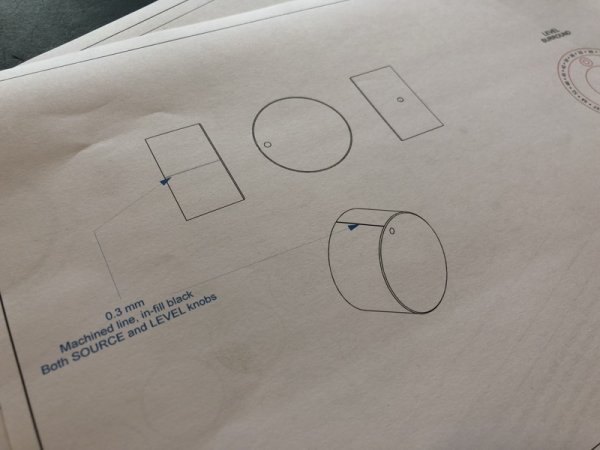

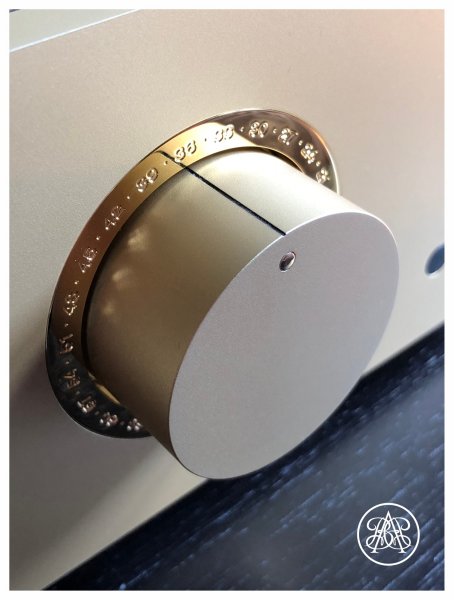

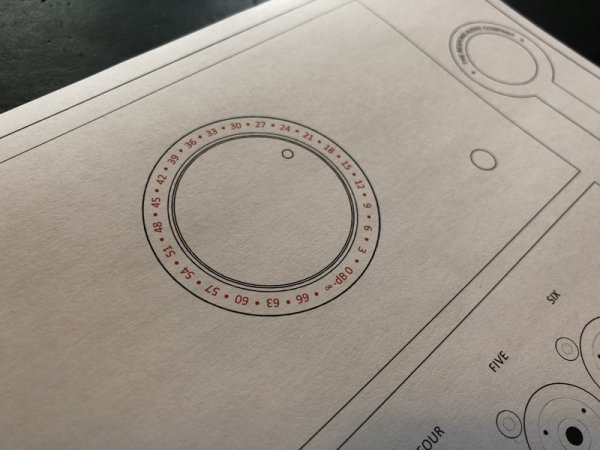

Our products are all made to order and to the customer's specification. Sometimes customers have very specific requests and recently a gentleman wished to have dB markings around his LEVEL control. In addition, he asked that thin lines be machined along the edge of the knob and then infilled so that he could easily identify the exact setting.

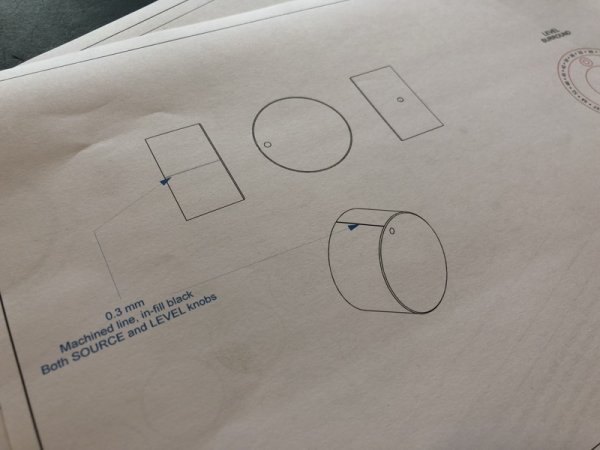

The first stage in every pre-amplifier we make is to send detailed drawings of the design to the customer so they can check and approve each stage...

The first stage in every pre-amplifier we make is to send detailed drawings of the design to the customer so they can check and approve each stage...