Kuzma SAFIR 9

- Thread starter Marcus

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A £20,000 arm with a cardboard template. That is rather ludicrous - why not add £200 and give a decent jig?The Safir's template is quite problematic, the cardboard paper tends to be uneven and difficult to read. What templates do you use? The original tonearm geometry is Baerwald, has anyone tried Loefgren or maybe even SAT?

Both devices are malfunctioning as their pins in the gauge can't be placed exactly over the SAFIR's pivot point.Any of the pivot to spindle measuring devices. I use Smart Tractor , Feickert will work as well.

Both will give you mounting hole location and cartridge alignment curve choices ( Smart tractor)

I have the SmarTracker and have no trouble getting the pin to sit/hit exactly on the indent of the Safirs pivot point either using on a Stabi R or the CSPORT TAT1M2.Both devices are malfunctioning as their pins in the gauge can't be placed exactly over the SAFIR's pivot point.

What do you mean by malfunctioning ? I use the older version of the Feickert, with a LP size protractor and a separate measuring arm, with no problem at all!Both devices are malfunctioning as their pins in the gauge can't be placed exactly over the SAFIR's pivot point.

Can you post a photo of the problem?

As soon as the arm assembly rests on the arm tower the pivot point is masked. The horizontal pivot point mark ontop of the assembly is moving with the position of the arm. So you can't use this to determine the correct pivot point.What do you mean by malfunctioning ? I use the older version of the Feickert, with a LP size protractor and a separate measuring arm, with no problem at all!

Can you post a photo of the problem?

You could use the Wally Tractor Universal V2.01 which comes with a spindle to tonearm pivot point rule !As soon as the arm assembly rests on the arm tower the pivot point is masked. The horizontal pivot point mark ontop of the assembly is moving with the position of the arm. So you can't use this to determine the correct pivot point.

It's a great tool (like all of the Wally Tools)

WallyTractor Universal v2.2 | WallyTools

Cartridge alignment doesn't get more accurate or universally applicable than it does when you use a WallyTractor Universal. Start from Certainty! Includes laser etched pivot to spindle ruler, spindle jig and 10x magnifying loupe. For more info click HERE

www.wallyanalog.com

www.wallyanalog.com

Oh, I think I know what you mean now! I just check it on my Safir, and this is the situation. If you use the cueing lever to cue up the arm, then the dimple will be a very tiny bit off the normal position, since the armtube / centre block will be tilted up slightly. So, if you move the the arm from the outside towards the centre with the cueing lever up, you will see some very slight movement of the dimple / marking, which I estimate to be way less than 1mm.As soon as the arm assembly rests on the arm tower the pivot point is masked. The horizontal pivot point mark ontop of the assembly is moving with the position of the arm. So you can't use this to determine the correct pivot point.

However, if you lower the cueing lever, so the arm is in the normal playing position (armtube parallel to platter) , then the dimple / marking would not move with the position of the arm.

Thank you for pointing this out, I have never thought of that !

Last edited:

Oh, I think I know what you mean now! I just check it on my Safir, and this is the situation. If you use the cueing lever to cue up the arm, then the dimple will be a very tiny bit off the normal position, since the armtube / centre block will be tilted up slightly. So, if you move the the arm from the outside towards the centre with the cueing lever up, you will see some very slight movement of the dimple / marking, which I estimate to be way less than 1mm.

However, if you lower the cueing lever, so the arm is in the normal playing position (armtube parallel to platter) , then the dimple / marking would not move with the position of the arm.

If the arm is in the arm rest (cueing down) is the dimple off by the small amount you describe because the center block is tilted up?

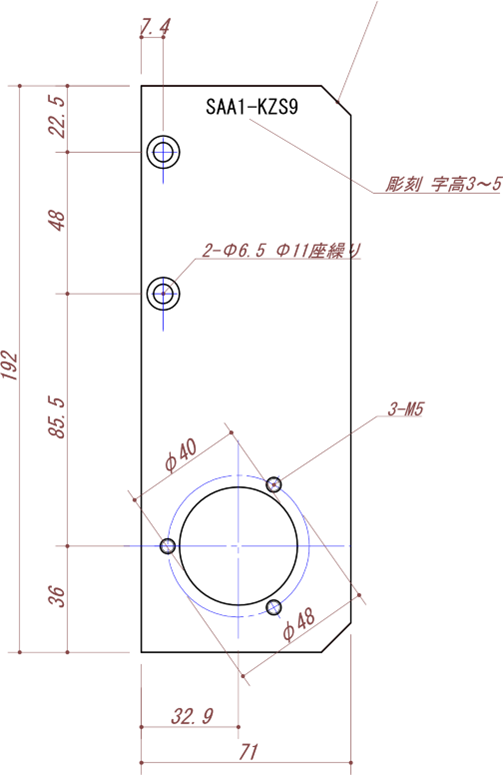

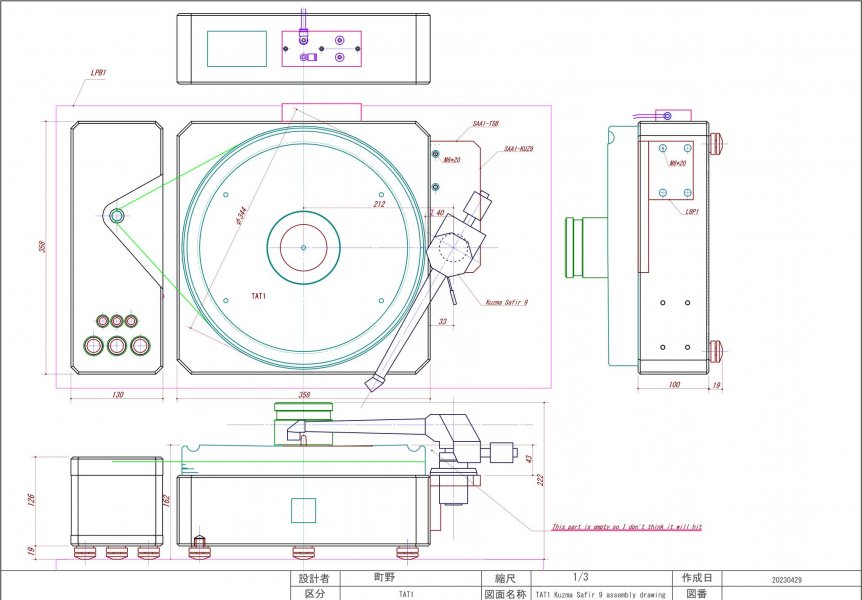

I don't have one to look at, but thinking out loud ... Looking at the diagram with measurements from the Kuzma site, it shows the arm in its rest and the top appears parallel to the arm mounting plate. see attached Kuzma pdf.

edit: if the cueing is up, methinks the arm is slightly higher and could be tilted back. When I do this on my 11" 4P with the Uni-PRO I keep the arm in its rest.

Attachments

Last edited:

Hi Tima, I have to check on the Safir tomorrow. However, with the 4Point11, the top of the armtube assembly is open, so you can check the horizontal pivot point directly on the top of bearing housing. Also, this marking on top of the bearing housing should not move with the arm’s position, as it is independent from the vertical movement, correct?

Thank you, the Wally Tractor is the perfect tool I'm looking for! Setting the correct mounting distance is plain, so its pivot to spindle ruler is not necessary. Important is that an 9 inch arc is provided to dial in the effective lenght!You could use the Wally Tractor Universal V2.01 which comes with a spindle to tonearm pivot point rule !

It's a great tool (like all of the Wally Tools)

WallyTractor Universal v2.2 | WallyTools

Cartridge alignment doesn't get more accurate or universally applicable than it does when you use a WallyTractor Universal. Start from Certainty! Includes laser etched pivot to spindle ruler, spindle jig and 10x magnifying loupe. For more info click HEREwww.wallyanalog.com

Sorry, a bit off topic (I will be posting such information and more on a specific Wally Tools thread), but I think it is very important to add especially if you have an expensive TT, Tonearm and Cartridge (in order to get the best out of them);Thank you, the Wally Tractor is the perfect tool I'm looking for! Setting the correct mounting distance is plain, so its pivot to spindle ruler is not necessary. Important is that an 9 inch arc is provided to dial in the effective lenght!

If you can also buy (or loan) the other Wally Tools i.e. in particular the 'WallyReference' and the 'WallySkater' / 'WallySkater Pro' (WallySkater Pro is excellent) you will be able to get your tonearm perfectly parallel to the platter (as a starting point for your cartridge's VTA and SRA etc.) and also see if your tonearm has additional unwanted horizontal forces (that will be added above the tonearm's anti-skate force) that are inherent to the design of the tonearm or tonearm wiring etc. that you didn't know about.

I now have all of the Wally Tools now (including the WallyScope for checking the static and dynamic SRA and VTA with the online Wally Tools Calculator and checking the condition of my stylus) and it has transformed in a big positive way what I am now hearing from my vinyl collection (not including checking any Zenith Error for my cartridge yet with a Wally Tool (and correcting it with the 'WallyZenith' tool that is available to buy) as awaiting for Wally Tools to bring out the tool for checking any zenith error hopefully by the end of this year). However, when I finally get (been waiting well over 8 weeks now for the AnalogMagik UK Dealer to obtain and send to me) the V2 upgrade for my V1 of AnalogMagik, I could check for any zenith error with AnalogMagik (although not sure how accurate this would be) and then correct it (if it needs correcting) with the 'WallyZenith' tool.

J.R. Bolsclair from Wally Tools has also been a major influence with my results from using the Wally Tools both from his great and very helpful YouTube videos and video blogs etc. to his own personal input via emails (which he always answers within 24 hours of me sending a question to him). Therefore I have found that Wally Tools customer service has also been great.

Sorry it is 'J.R. Boisclair' not 'Bolsclair.' Sorry J.R. (if you come across my WBF post above) !Sorry, a bit off topic (I will be posting such information and more on a specific Wally Tools thread), but I think it is very important to add especially if you have an expensive TT, Tonearm and Cartridge (in order to get the best out of them);

If you can also buy (or loan) the other Wally Tools i.e. in particular the 'WallyReference' and the 'WallySkater' / 'WallySkater Pro' (WallySkater Pro is excellent) you will be able to get your tonearm perfectly parallel to the platter (as a starting point for your cartridge's VTA and SRA etc.) and also see if your tonearm has additional unwanted horizontal forces (that will be added above the tonearm's anti-skate force) that are inherent to the design of the tonearm or tonearm wiring etc. that you didn't know about.

I now have all of the Wally Tools now (including the WallyScope for checking the static and dynamic SRA and VTA with the online Wally Tools Calculator and checking the condition of my stylus) and it has transformed in a big positive way what I am now hearing from my vinyl collection (not including checking any Zenith Error for my cartridge yet with a Wally Tool (and correcting it with the 'WallyZenith' tool that is available to buy) as awaiting for Wally Tools to bring out the tool for checking any zenith error hopefully by the end of this year). However, when I finally get (been waiting well over 8 weeks now for the AnalogMagik UK Dealer to obtain and send to me) the V2 upgrade for my V1 of AnalogMagik, I could check for any zenith error with AnalogMagik (although not sure how accurate this would be) and then correct it (if it needs correcting) with the 'WallyZenith' tool.

J.R. Bolsclair from Wally Tools has also been a major influence with my results from using the Wally Tools both from his great and very helpful YouTube videos and video blogs etc. to his own personal input via emails (which he always answers within 24 hours of me sending a question to him). Therefore I have found that Wally Tools customer service has also been great.

Hi Tima, I have to check on the Safir tomorrow. However, with the 4Point11, the top of the armtube assembly is open, so you can check the horizontal pivot point directly on the top of bearing housing. Also, this marking on top of the bearing housing should not move with the arm’s position, as it is independent from the vertical movement, correct?

Thanks kong, I'm curious about the Safir.

Wrt the 11" 4P, yes, the dimple at the top of the horizontal bearing sleeve is available for access. Older 4Ps have a spot or target there for locating a P2S spike, but no actual dimple. Yes, you have it right, that dimple/spot does not move relative to the arm's movement, although the entire bearing assembly (tower plus vertical bearing cups) rotates with the arm.

There are pictures and a diagram in my write-up:

Kuzma 4Point tonearm4Point Bejeweled – A Guided Tour of an Improved Kuzma Tonearm - Positive Feedback

Kuzma 4Point tonearm review

If using the ACOUSTICAL SYSTEMS - SMARTractor Alignment Tool here's a great YouTube video of how to use it when measuring the P2S distance.

Hi Tima, I have checked, when the Safir is in the arm rest, the armtube actually tilted up very slightly !If the arm is in the arm rest (cueing down) is the dimple off by the small amount you describe because the center block is tilted up?

I don't have one to look at, but thinking out loud ... Looking at the diagram with measurements from the Kuzma site, it shows the arm in its rest and the top appears parallel to the arm mounting plate. see attached Kuzma pdf.

edit: if the cueing is up, methinks the arm is slightly higher and could be tilted back. When I do this on my 11" 4P with the Uni-PRO I keep the arm in its rest.

Yes … There is a faint whiff of Gents Urinal Soap Dispenser about the design imho , however … it is all about the audio fidelity that matters most after allI visited a good friend of mine yesterday, to witness the "openbox" & setting up of his new Kuzma Safir 9 tonearm.

The turntable is Transrotor Tourbillon and the cartridge is a humble Eisteddfod Audio MC Blue cartridge.

The arm-tube is made of sapphire but IMO it's rather ugly, looking like a whitish wax candle.

View attachment 101441

Despite that the look was unattractive, the sonic performance was a big surprise.

Similar threads

- Replies

- 1

- Views

- 1K

- Replies

- 8

- Views

- 1K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |