Is it an AC synchronous motor?I think the Falcon controls the speed by hunting and correcting. The AS2000 has no correction. It relies on the 150 lb platter mass, very low bearing friction, and high quality motor for speed stability. The motor spins at a constant speed based on voltage. It does not need the Folcan for correction.

It is just a different approach to speed stability and it affects the sound.

Natural Sound

- Thread starter PeterA

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it an AC synchronous motor?

As far as I know, the Papst hskz 32 80 440d three phase motor. Peter was mistaken in his answer , the speed is controlled by frequency, not voltage. Voltage is adjusted for best torque with minimal noise.

Turntables with synchronous motors can be extremely speed accurate - the user adjusts the frequency of the controller at start up for desired speed.

Some TechDas turntables do it automatically at start up using the platter tachometer and from there on, the frequency is locked - no more feedback.

Some people prefer using these motors with three phase controllers, other prefer single phase with a de-phasing capacitor.

This is so true Peter, your video sound comes across as very natural and can be watched all the way through unlike some members videos of their digital systems...Al, there is a big difference. Natural sound is demonstrated using simple phone videos over YouTube.

Last edited:

Hunt and seek then

Curiously, some people could say that synchronous motors have an intrinsic hunt and seek mechanism - if they become retarded by load variations they increase current to accelerate and compensate for it.

99.99% of time synchronous motors in turntables are being overdriven, not optimally driven - no one optimises the controller for the specific motor unit and motors have significant. The differences Peter reports on sound quality when tensioning the belt are probably also due to changing the load in the motor.

A direct drive motor can be easily operated without feedback, in synchronous mode. However designers found that operation with proper feedback made them run much smoothly, with less noise - it is why this mode is preferred. Interested people can read about the subject looking for BDLC motors in the diyaudio.com- we find here projects using these brushless motors in both configurations. Again, reading the papers from Grand Prix Audio is also mandatory.

There is no absolute perfection in electro-mechanics, as well as in analog or digital. As expected we can learn a tot about a type of drive reading the technical bulletins of engineers defending alternative approaches. Competition stimulates progress.

Curiously, some people could say that synchronous motors have an intrinsic hunt and seek mechanism - if they become retarded by load variations they increase current to accelerate and compensate for it.

99.99% of time synchronous motors in turntables are being overdriven, not optimally driven - no one optimises the controller for the specific motor unit and motors have significant. The differences Peter reports on sound quality when tensioning the belt are probably also due to changing the load in the motor.

A direct drive motor can be easily operated without feedback, in synchronous mode. However designers found that operation with proper feedback made them run much smoothly, with less noise - it is why this mode is preferred. Interested people can read about the subject looking for BDLC motors in the diyaudio.com- we find here projects using these brushless motors in both configurations. Again, reading the papers from Grand Prix Audio is also mandatory.

There is no absolute perfection in electro-mechanics, as well as in analog or digital. As expected we can learn a tot about a type of drive reading the technical bulletins of engineers defending alternative approaches. Competition stimulates progress.

all the DDs I heard in person had lack of flow stop start issue. Mike’s NVS was an exception to that. It is also clearly audible in Fremer’s videos he posted comparing OMA to AF3p, and another sent to me by an user comparing OMA technics to a Garrard

(...) Mike’s NVS was an exception to that.(...)

Happy you acknowledge this exception. It is the real proof that the problem is implementation or system matching, not the theory.

In this hobby, exceptions can be a Pandora box. Once we open it is not possible to close it.

Happy you acknowledge this exception. It is the real proof that the problem is implementation or system matching, not the theory.

In this hobby, exceptions can be a Pandora box. Once we open it is not possible to close it.

Sure but it will be easier, surer, and as Mike too has done it…eventually replace the DD with a belt and non-DD drive (esoteric has its own magnetic drive).

The exception to the DD does not make it the best table, so what’s the point? Unless DD and TT drives is your sub hobby and you want to conquer that challenge.

As far as I know, the Papst hskz 32 80 440d three phase motor. Peter was mistaken in his answer , the speed is controlled by frequency, not voltage. Voltage is adjusted for best torque with minimal noise.

Turntables with synchronous motors can be extremely speed accurate - the user adjusts the frequency of the controller at start up for desired speed.

Some TechDas turntables do it automatically at start up using the platter tachometer and from there on, the frequency is locked - no more feedback.

Some people prefer using these motors with three phase controllers, other prefer single phase with a de-phasing capacitor.

Thank you. Yes, I was mistaken. It is controlled by frequency which is adjusted manually based on the reading of platter speed. I adjust thread tension and frequency to get the right speed. I try different combinations of the two and choose which sounds best to me. I was trying to explain that the motor runs at a constant speed and that the motor does not adjust speed based on the reading from the RoadRunner tachometer.

Happy you acknowledge this exception. It is the real proof that the problem is implementation or system matching, not the theory.

In this hobby, exceptions can be a Pandora box. Once we open it is not possible to close it.

Are you getting a deal on the OMA K3 prototype is Fremer letting it go?

Sure but it will be easier, surer, and as Mike too has done it…eventually replace the DD with a belt and non-DD drive (esoteric has its own magnetic drive).

And probably will change again someday ... I doesn't change my point.

We should remember that we know very little about the "magnetic synchronization" system and the control system of the Grandioso T1.

The exception to the DD does not make it the best table, so what’s the point? Unless DD and TT drives is your sub hobby and you want to conquer that challenge.

As I have written in another post there is not a single "best" , just our preference. This is not relevant to my comment.

Esoteric, of course, is a rim-drive idler, with magnetic drive. not a DD. it also allows for adding a clock for additional added flow....Sure but it will be easier, surer, and as Mike too has done it…eventually replace the DD with a belt and non-DD drive (esoteric has its own magnetic drive).

that NVS was a much later build than my first one, and a different algorithm for the motor. a noticeable improvement. so it's execution, not dogma, that is the limiting factor. but DD does require more of it to get past motor design limitations. my Rockport Sirius III DD with the eddy current motor had flow squared.The exception to the DD does not make it the best table, so what’s the point? Unless DD and TT drives is your sub hobby and you want to conquer that challenge.

As I have written in another post there is not a single "best" , just our preference.

By definition "best" is what Bonzo prefers.

Not quite true Bill Carlin from Phoenix Engineering built a 3 phase controller for a specific BDLC motor that can receive feedback from the Roadrunner. It is licensed to SOTA turntables and sold as a set. https://sotaturntables.com/product-category/eclipse-series/Curiously, some people could say that synchronous motors have an intrinsic hunt and seek mechanism - if they become retarded by load variations they increase current to accelerate and compensate for it.

99.99% of time synchronous motors in turntables are being overdriven, not optimally driven - no one optimises the controller for the specific motor unit and motors have significant. The differences Peter reports on sound quality when tensioning the belt are probably also due to changing the load in the motor.

A direct drive motor can be easily operated without feedback, in synchronous mode. However designers found that operation with proper feedback made them run much smoothly, with less noise - it is why this mode is preferred. Interested people can read about the subject looking for BDLC motors in the diyaudio.com- we find here projects using these brushless motors in both configurations. Again, reading the papers from Grand Prix Audio is also mandatory.

There is no absolute perfection in electro-mechanics, as well as in analog or digital. As expected we can learn a tot about a type of drive reading the technical bulletins of engineers defending alternative approaches. Competition stimulates progress.

He also designed a 3 phase controller specifically for the Papst motor used in "The Absolute Nothing" turntable, a lot of time and measurements partly with the turntable running, was used to build this controller.

Not quite true Bill Carlin from Phoenix Engineering built a 3 phase controller for a specific BDLC motor that can receive feedback from the Roadrunner. It is licensed to SOTA turntables and sold as a set. https://sotaturntables.com/product-category/eclipse-series/

He also designed a 3 phase controller specifically for the Papst motor used in "The Absolute Nothing" turntable, a lot of time and measurements partly with the turntable running, was used to build this controller.

Yes. Bill also designed the controller specifically for that same Papst motor used in my AS2000.

Not quite true Bill Carlin from Phoenix Engineering built a 3 phase controller for a specific BDLC motor that can receive feedback from the Roadrunner. It is licensed to SOTA turntables and sold as a set. https://sotaturntables.com/product-category/eclipse-series/

He also designed a 3 phase controller specifically for the Papst motor used in "The Absolute Nothing" turntable, a lot of time and measurements partly with the turntable running, was used to build this controller.

If you had read my posts more carefully and knew what is exactly this specific BDLC motor you would see I addressed this case in a general way. Many BDLC motors can be used with a 3 Phase AC Sinewave generator. It is an old audiodiy.com project. BTW, BDLC is a general acronym for a type of motor - fortunately my vacuum cleaner has one.

And the excellent controller / motor system developed Bill Carlin from Phoenix Engineering for the The Absolute Nothing" surely is included in the remaining .01% I referred. Or should I have written 99.9999%? BTW, this system was sold by Bill Carlin before "The Absolute Nothing" - 3 Phase AC Sinewave generators are not rocket science.

Here you can see how people from the Lencoheaven forum take it seriously :

https://www.lencoheaven.net/forum/index.php?topic=19557.0

Edit: Sorry, I forgot you only use your ears ...

Last edited:

Don’t these have brushes? I think they run straight off 24V DC. A BLDC needs to have some kind of commutation, like a sine wave, to work. Also, while some of these are slotless, they still have Iron in the stator and therefore aome torque ripple.is probably the most used motor at the moment, is in many turntables e.g. kronos,continiuum etc. They make motors for direct drive too

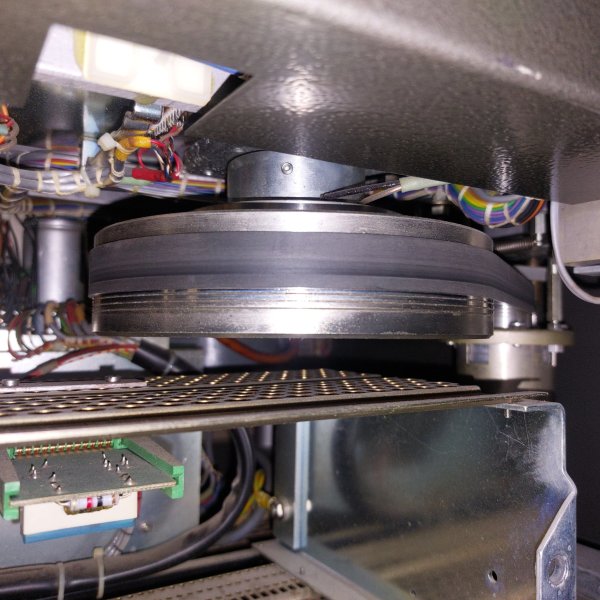

View attachment 143462

delivers 2400 pulses per rotation of the axis with encoder.

All these AC synchronous motors will have plenty of torque ripple that can only be smoothed by a belt but not eliminated.

The only motors with inherently almost no torque ripple are pancake coreless motors that are either brush or brushless. All the great Japanese (and German Dual) motors were of this type. Brinkmann now uses the same…even for their Nalance belt drive.

Yes, you should definitely not have written " no one optimises the controller for the specific motor unit " and i corrected you professor !If you had read my posts more carefully and knew what is exactly this specific BDLC motor you would see I addressed this case in a general way. Many BDLC motors can be used with a 3 Phase AC Sinewave generator. It is an old audiodiy.com project. BTW, BDLC is a general acronym for a type of motor - fortunately my vacuum cleaner has one.

And the excellent controller / motor system developed Bill Carlin from Phoenix Engineering for the The Absolute Nothing" surely is included in the remaining .01% I referred. Or should I have written 99.9999%? BTW, this system was sold by Bill Carlin before "The Absolute Nothing" - 3 Phase AC Sinewave generators are not rocket science.

Here you can see how people from the Lencoheaven forum take it seriously :

https://www.lencoheaven.net/forum/index.php?topic=19557.0

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 12

- Views

- 2K

- Replies

- 2

- Views

- 520

- Replies

- 49

- Views

- 5K

- Replies

- 10

- Views

- 825

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |