On the subject of tweaks!

- Thread starter ddk

- Start date

-

- Tags

- daiza panzerholtz tweaks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

You have a good ear. Earlier today I had a power outage right when I was going to make the non CC video. It is very possible that the volume is not matched exactly. The volume level was set at 9:10 as this tape is very "hot"The f

The first video seems brighter and has more dynamics. The soundstage seems clearer. Sound is more coherence and even in all regions.

It seems both video is playing at different volumes but the difference is distinguished.

Maybe the phone is lying to us.

I tend to agree after becoming familiar with both videos. But as expressed by a few of us that like to make videos available,the whole SQ is not faithfully captured. But one thing, you cannot fake clarity and a lack of stress. Not many post very involved classical music for a reason...but that's just my personal opinion. Thanks Hieukm

It's tough; after listening few times to passages to get familiar with I do hear differences.

Here so far (because I'm not done yet...I'll have to plug my laptop to my main sound system):

The second video comes up as more exciting but, on busy passages it also seems more congested than the first video which perhaps less exciting appears less congested.

This is a quick first impression and I'm not sure about levels matching as you guys mentioned some to that effect (outtage).

I'll have to get back on that...the laptop speakers is not the best indicator for this particular test here...IMO; it requires a better setting and listening.

* I can't believe that I'm listening to audio power cables...this is like . . . an audio tweak (tweet) impeachment.

Here so far (because I'm not done yet...I'll have to plug my laptop to my main sound system):

The second video comes up as more exciting but, on busy passages it also seems more congested than the first video which perhaps less exciting appears less congested.

This is a quick first impression and I'm not sure about levels matching as you guys mentioned some to that effect (outtage).

I'll have to get back on that...the laptop speakers is not the best indicator for this particular test here...IMO; it requires a better setting and listening.

* I can't believe that I'm listening to audio power cables...this is like . . . an audio tweak (tweet) impeachment.

For copyright reasons I moved the two test videos to private.

I think a fair amount of listeners that I respect favor the CC cord. For me it was a enlightening test.

I think a fair amount of listeners that I respect favor the CC cord. For me it was a enlightening test.

The music is subject to copyright law and not published. So the video is now private. The videos were a experiment for me and I shared it for a time.How you do that?

* Roger, what did you do?

Oh I see, the music ...

Can you redo the test but this time with Led Zeppelin? ...Something everyone use on YouTube.

Can you redo the test but this time with Led Zeppelin? ...Something everyone use on YouTube.

Bob,Oh I see, the music ...

Can you redo the test but this time with Led Zeppelin? ...Something everyone use on YouTube.

I have the CD only. Stairway to heaven should be fine. Tomorrow probably

Let me see if I can find my Sarah Vaughn 2 track since the CC is setup on my RTRBob,

I have the CD only. Stairway to heaven should be fine. Tomorrow probably

Yeah because it's a bummer that you took the time to setup, record, and posted the two audio test videos only to render them obsolete due to music copyright.

I wanted to analyse them further...it's fun and that's what's it's all about ... the search to audio musical fulfillment ... the apotheosis of nirvana bliss/wisdom.

I wanted to analyse them further...it's fun and that's what's it's all about ... the search to audio musical fulfillment ... the apotheosis of nirvana bliss/wisdom.

I'm reposting a copy of this thread here because I feel it has a lot of relevance here, more so than the original thread. Also none of the points I brought up were ever discussed or replied to.

Hi Emile,

I’m on the record here with my views on the Stable Table and it’s use under turntables. I agree with your assessment of the aluminum plate and understand that by placing the panzerholz on top and bottom of the unit you accomplish two things, deal with the aluminum plate and dull the reaction of the Stable Table from external influences, basically dealing with a non-existent problem that this tech introduced by sticking it where it doesn’t belong. Let’s be clear, Stable Table is a piece of cold tech and has nothing to do with musical instruments and their function. I appreciate your approach to solve a puzzle but I don’t see how your charts of materials translate to their interaction with a turntable sitting on top of a reactive instrument with continuous random resonance. From what you correctly stated and my knowledge it’s obvious that Stable Table was more of a Stable Nightmare. In this scenario my approach would be to eliminate the source of the problem and you decided to keep the problem and go through a lot of trouble trying to lessen negative effects of a component that you can’t change it without reversing it’s function.

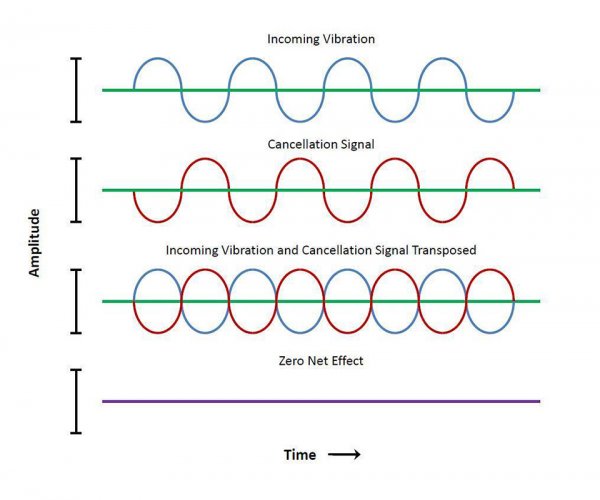

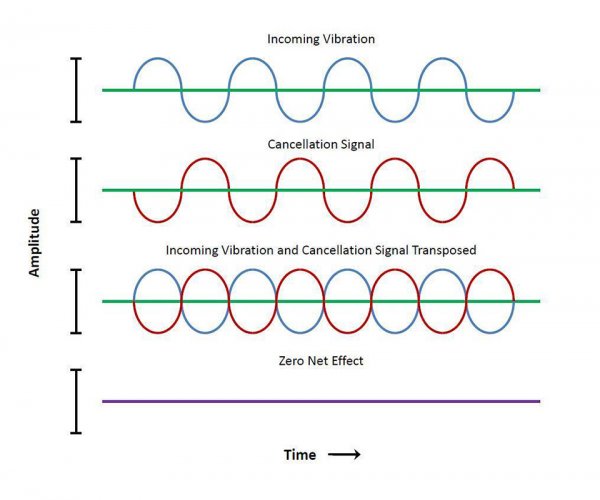

Stable Table is a scientific instrument initially designed for a very specific purpose and in context of a motionless instrument. A turntable isn’t a digital box, it’s a living, moving musical instrument all about resonance and vibration, direct opposite in nature of what the Stable Table was designed to deal with. Aside from CD players with digital your primary concern is math and computation, resonance and tuning are secondary. Turntable systems are mechanical objects, it’s all about resonance and vibration. The motor is running, the platter is spinning, the bearing rumbling while a tiny stylus connected to fragile cantilever is working hard to create a perfect signal. Every tuning and detuning decision we make with a turntable has to do with controlling the resonance because the mechanism presenting the grooves to the stylus has a profound affect on the outcome. Then we have to preserve the unhindered continuous flow of those miniscule resonances to the conversion point to electric signal which still needs to be kept intact and alive until handoff to the next link in the chain. The vinyl playback system is voiced by controlling resonance, it’s our language and the way we communicate with the listener then you come and stick an effective resonance killer attacking the heart of the system with death as it’s mission as portrayed with the final flat line in the representation below. What have you changed with a couple pieces of plywood and some footers? Call it tuning or whatever else you want, the machine is still a sound killer. I’m a simple guy I don’t understand the rational of sticking one of these units under a turntable and ruining your sound. Daiza is another sample of the same irrationality, out of all the materials you could have chosen for this purpose you pick the well known sound killer to play with. What do you think has changed in nature of panzerholz by cutting grooves and sticking foam up it’s cracks? You even gave the madness a name. Yes you can call it voicing, tuning or whatever else you want, I disagree with your bottom line based on what I hear. Daiza definitely isn’t neutral and has the same sonic impact as panzerholz with the same dampening properties stripping the music off everything that matters.

The below diagram is from Herzan’s site, note the final goal depicted by the purple flatline of death and the last thing you want under a turntable is all the counteractive vibration created by the platform's actuators!

david

Hi David, thank you for your reply. We are not looking for alternative materials, but I am interested in your experiences. Let me take the opportunity to explain why. Most of what I'm about to write is known to you, so do not consider this to be directly addressed to you, it may however be interesting to others.

We started using panzerholz about 2.5 years ago to solve address an issue we found when we started modifying the Table Stable active platforms. The issue was these active platforms "isolate" up to 200Hz, in order to do that the feedback circuit measures up to 2000Hz to account for harmonics, as a 200Hz resonance will have harmonics at 400Hz, 600Hz, 800Hz etc. They are fitted with an aluminium top platter sandwiched to a steel frame which causes no issues below 2000Hz. However Aluminium is very resonant above 2000Hz. It's resonance spectrum does not complement any type of musical instrument behaviour so we consider this an undesirable trait.

For painting a complete picture, material resonant behaviour is what makes musical instruments function. In stringed instrument, like a Violin or a guitar, the sound radiation source is mainly a top plate, in pianos it's a soundboard. The strings excite the natural resonances of the top plate/soundboard which are usually made out of wood. The wood provides a dual function, amplification, as it will amplify at its resonance frequencies, and damping, as it will damp some the high frequency resonance of the strings. Spruce is most often used as a soundboard material as it has low density and low internal friction (damping). Maple has higher density and higher internal friction, usually only used to construct the casing. Engineered woods can have even higher density and internal friction. Interestingly one of the applications of Panzerholz is to serve as the frame on which soundboards can be mounted in grand pianos.

View attachment 58937

So we tried a lot of materials, a whole range of wood types, the highest damping woods however came with strong resonance modes in the midrange, both upsetting the Table Stable feedback circuitry and obviously colouring the sound. Bamboo plywood was the best compromise between low midrange colouration and damping aluminium resonance as far as natural wood goes. Composite Bamboo did a bit better, but still not well enough. Then we tried a whole range of high damping composite materials, stones and artificial stones with varying results and finally ended up trying Panzerholz which did the best job by far. We ended up with replacing the stock 6mm aluminium top cover with a 10mm one and sandwiching it with 10mm Panzerholz.

Later on we discovered placing the Table Stable on top of a 40mm board of Panzerholz and adding another on top improved performance even more. Then we got enquiries from customers who wanted to try Panzerholz boards stand alone, so we shipped a bunch out, received feedback claiming good potential, incredible bass, significant increases in clarity but a bit of a "hard quality" to the upper midrange/lower highs, some upper midrange smearing and we should do something with it. So we did, we discovered there where some small modes in the range centered around 3K, we moved those to over 20K by machining all sorts of patterns into the Panzerholz, ended up with the current design as it has no repeatable distances across the board, think diffusion without repeating distances for a sound room. This took care of the upper midrange modes and the associated smearing. Then we had to address the hard quality to the upper midrange/lower highs.This had us baffled for a long time until a conversation with Table Stable introduced the concept of micro oscillations to us. Everything oscillates. Even 2 surfaces, bolted rigidly together, are subject to micro oscillations between them. This is for example what can loosen bolts over time. Even large masses are subject to this. You can move very heavy objects with minimal force if the surface beneath it vibrates. Another example, Tiny Multi Layer Ceramic Capacitors can vibrate significantly when exposed to AC voltages, they can even break off the PCB over time, as they actually cause PCBs to slightly warp under the vibrations they emit. Guess why nobody likes to use those in Hi-Fi.

View attachment 58938

The upper midrange/lower highs harshness was the whole board, with appliance on top, literally bouncing on the floor. An easy way out is using compliant footers, like rubber. But these have a side effect. They create a spring-mass system, the frequency response of this is the lower range passes through, up till the resonance frequency of the system where it amplifies (!), after which it starts damping. The amount of damping defines the amplitude of the resonance peak. This is NOT a neutral Frequency response:

View attachment 58939

If the compliant medium (rubber) is stiff, this can be way up the frequency range, up into the midrange for example. So we came up with the not rigidly mounted footer system damped by foam. Micro oscillations are damped and it has no resonance peak.

Now I've been writing the foams affect the high frequency damping. That is actually a gross oversimplification, if you remove any of those, you start introducing a degree of micro oscillations. That sounds wrong, but it isn't really, as it is just a way of voicing. Ultimately voicing is all about managing resonances. You introduce them in all kinds of flavours, like seasoning in cooking, a bit of spruce here, a little bit of maple there, maybe add a touch of copper, or maybe your dish needs a hint of silver?

Bottom line, the Daiza is virtually neutral. But do you want it to be neutral? Or do you want to use it to add some flavour?

Hi Emile,

I’m on the record here with my views on the Stable Table and it’s use under turntables. I agree with your assessment of the aluminum plate and understand that by placing the panzerholz on top and bottom of the unit you accomplish two things, deal with the aluminum plate and dull the reaction of the Stable Table from external influences, basically dealing with a non-existent problem that this tech introduced by sticking it where it doesn’t belong. Let’s be clear, Stable Table is a piece of cold tech and has nothing to do with musical instruments and their function. I appreciate your approach to solve a puzzle but I don’t see how your charts of materials translate to their interaction with a turntable sitting on top of a reactive instrument with continuous random resonance. From what you correctly stated and my knowledge it’s obvious that Stable Table was more of a Stable Nightmare. In this scenario my approach would be to eliminate the source of the problem and you decided to keep the problem and go through a lot of trouble trying to lessen negative effects of a component that you can’t change it without reversing it’s function.

Stable Table is a scientific instrument initially designed for a very specific purpose and in context of a motionless instrument. A turntable isn’t a digital box, it’s a living, moving musical instrument all about resonance and vibration, direct opposite in nature of what the Stable Table was designed to deal with. Aside from CD players with digital your primary concern is math and computation, resonance and tuning are secondary. Turntable systems are mechanical objects, it’s all about resonance and vibration. The motor is running, the platter is spinning, the bearing rumbling while a tiny stylus connected to fragile cantilever is working hard to create a perfect signal. Every tuning and detuning decision we make with a turntable has to do with controlling the resonance because the mechanism presenting the grooves to the stylus has a profound affect on the outcome. Then we have to preserve the unhindered continuous flow of those miniscule resonances to the conversion point to electric signal which still needs to be kept intact and alive until handoff to the next link in the chain. The vinyl playback system is voiced by controlling resonance, it’s our language and the way we communicate with the listener then you come and stick an effective resonance killer attacking the heart of the system with death as it’s mission as portrayed with the final flat line in the representation below. What have you changed with a couple pieces of plywood and some footers? Call it tuning or whatever else you want, the machine is still a sound killer. I’m a simple guy I don’t understand the rational of sticking one of these units under a turntable and ruining your sound. Daiza is another sample of the same irrationality, out of all the materials you could have chosen for this purpose you pick the well known sound killer to play with. What do you think has changed in nature of panzerholz by cutting grooves and sticking foam up it’s cracks? You even gave the madness a name. Yes you can call it voicing, tuning or whatever else you want, I disagree with your bottom line based on what I hear. Daiza definitely isn’t neutral and has the same sonic impact as panzerholz with the same dampening properties stripping the music off everything that matters.

The below diagram is from Herzan’s site, note the final goal depicted by the purple flatline of death and the last thing you want under a turntable is all the counteractive vibration created by the platform's actuators!

david

David I wanted to ask you this included in my previous post, but was cut off by a customer walking in. Just to be clear, I love tweaking and voicing, and from time to time I introduce colouration in my system on purpose. Its very easy to do, although I prefer to introduce it into my room acoustics rather then my equipment. For example from time to time I tune the materials used on the first reflection points on the sidewalls with various flavours of wood. I have included frequency response measurements of various types of wood below. This is the material response from being subjected to a frequency sweep from 100 to 10.000Hz from a speaker mounted at a 2" distance from the board.

Sp1 and Sp2 are 2 variants of Sitka Spruce, He is Hemlock, Map is Maple, Mah is Mahogany, Mat is Matoa, Acryl is Acrylic Resin.

View attachment 58940

Now this is all obvious, when hit by soundwaves the reflection will either not change, be amplified, or damped causing the sound Frequency Response to be modified.

Now suppose we use it as a material for a tonearm or a cartridge, or even turntable material, it would be very feasible it will modulate the cartridge operation by translating its vibration into an electrical signal . Would you agree to that?

Next, how do you propose it does this when used as a platform underneath, say a preamplifier made out of a metal chassis with circuit boards? How does it modulate the sound? And why would you prefer to use Maple or another hardwood for that with very obvious resonance modes? (colouration)? Is this, in your opinion, a way to add natural material resonance to the sound? Or are you doing it to introduce a degree of isolation by means of a deliberate surface to surface impedance mismatch for which there are obvious better choices?

I see two parts here Emile, first one has to do with materials, 2nd how and why. My response below is also related to your previous post.

1- The different random wood measurements you posted give no indication of application or how they convert to sound aside from some possible resonance peculiarity which is meaningless without context. One needs to take into account volume, shape, application and installation for measurements to have any meaning and if one’s methodology is only scientific and theoretical then you need to build a 3 dimensional mathematical model supporting the theory. Fortunately for all the best people making cartridges, tonearms, turntables and other such items are also artists with working experience of materials. A lot of the design work is done intuitively and emotionally and the final product as well engineered as it might be is still a self expression of the artist. Close to your location is Mr. van den Hul, he’s the complete package scientist and artist and I doubt you’re going to find anyone as knowledgeable and intuitive as him. Ask him about his process, use of materials and the various woods he uses in his designs, I very much doubt that he’s going to show you measurements.

2- I don’t build and sell wood platforms to change the sonic balance of equipment so I should ask you that same question, “how do you propose it does this when used under equipment with metal chassis and circuit boards? How does it modulate the sound?”

Please explain why when you transfer a digital file from one box to another over a 10cm connector the reproduced sound is affected and even drastically at times will change again using a different set of connectors and conductor yet when you open the transferred files they’re identical to the original. Explain the differences we hear with powercords and schuko. I’m not trying to catch you Emile just pointing out that in audio there’s a lot that we can’t explain or measure but we’re aware of their acoustic presence and connection to our psyche. To successfully navigate this unmeasurable one needs knowledge, experience and intuition. With panzerholz and your Daiza we know their physical properties but at the same time the way this material strips music of everything is difficult to explain, but we hear it.

No wood or other materials to tune equipment, there's Shun Mook for that. The only place I like to use wood is when dealing with a particular room node and depending on the environment and the frequency I decide the type of wood and design of the diffusor. What happened in Anthony’s install is unusual and I used a few pieces of wood as you suggested to introduce a degree of isolation but I have to be careful because there can be too much of a good thing.

david

I’m on the record here with my views on the Stable Table and it’s use under turntables.

david

Hi David,

I'm completely aware of your aversion to this technology. Yet there are several threads, I'm counting 8 in the "Vibration Control Forum", discussing the ins and outs of this, including applications for usage with turntables. So I'm not going to discuss this again.

“how do you propose it does this when used under equipment with metal chassis and circuit boards? How does it modulate the sound?”

It doesn't, that is the point I'm trying to make. You are claiming it "kills" the sound, so I'm interested in how you think it can do that.

What it does do, measurably, and you can even confirm this by a simple "knock" test, is reduce the time a metal chassis rings after being exited. It also decreases transformer hum, reduces capacitor microphonic distortion and lowers XO phase noise sensitivity to vibration. It's effect on tubes is interesting to investigate, but I have not done that yet. I'd say we would not disagree on a very direct impact on various parts of a vinyl playback system.

Atmasphere does not seem to think chassis damping would negatively impact performance according to the post quoted below. However I'm completely open to suggestions, and time permitting, even willing to investigate.

Spirit,

Just found this from the legendary Atmasphere himself when someone was asking about SRA:

"

atmasphere

6,951 posts

12-22-2010 4:11pm

It is impossible to mechanically over-damp audio equipment (I am not talking about electrical damping).

If you are of the opinion that this is not the case, then its likely that you are used to dealing with synergistic effects which is usually not a good way to set up a system.

Now it is possible to put so much damping product on a tube that you can damage the tube by overheating it, but this is an issue of heat rather than damping.

Let's say you are compensating for a brightness by using dull equipment elsewhere. The result may be an even tonality, but one that is lacking transparency and detail. You are much better off if the equipment stands on its own merits and lacks coloration on its own.

This is why a good stand for amplifiers or for the front end of the system is a good idea- the less vibration you have, the greater the ease that the gear can realize its musical potential."

2- I don’t build and sell wood platforms to change the sonic balance of equipment so I should ask you that same question, “how do you propose it does this when used under equipment with metal chassis and circuit boards? How does it modulate the sound?”

It doesn't, that is the point I'm trying to make. You are claiming it "kills" the sound, so I'm interested in how you think it can do that.

What it does do, measurably, and you can even confirm this by a simple "knock" test, is reduce the time a metal chassis rings after being exited. It also decreases transformer hum, reduces capacitor microphonic distortion and lowers XO phase noise sensitivity to vibration.

I don't understand. The antonym of 'modulate' is 'leave alone.' If the device leaves the sound alone, why use it?

Taiko, you describe physical changes to the operartion of electronics. If I understand him, David is describing the sonic impact - what we hear - as a result of the device's use.

I was under the impression the Daiza's purpose or goal was to alter the sound, regardless of how it works.

Is the debate about whether the physical changes occur or whether that alteration is for the better or the worse?

Hi Tima,

Every object is subject to resonance modes. Damping capacity or energy dissipation ability of a material affects the vibration amplitude and vibration time of resonance frequencies. Take a tuning fork as an example, the material and shape define its resonance frequency, damping affects amplitude and ring time. Now attach a piece of rubber or panzerholz to the tuning fork, the resonance frequency, resonance amplitude and ring time will change.

Now rubber or panzerholz are going to have a different effect when placed underneath a component. They both have good damping abilities but, a compliant material like rubber coupled to a mass creates a mass spring system. A mass spring system has its own resonance, when its resonance frequency is exited, it will start amplifying that frequency and starts ringing. Every material has a degree of compliance, whether its rubber, steel or panzerholz. The latter 2 are too stiff to introduce this effect to a significant enough degree.

The goal of the Daiza is not to alter the sound, it is to provide a minimal resonant surface on which to place your component. Resonance modes in Panzerholz are damped to a degree which is not available in other materials, it will hardly resonate, and it will hardly ring.

How this is all very interesting but there is more to it then just that. We have to consider how vibrational energy travels or couples from 1 object to the other. This is a highly complex model. If interested read here for an explanation of Acoustic Impedance:

https://en.wikipedia.org/wiki/Acoustic_impedance

One of the actors here is velocity of sound which is different in different materials, if we simplify the model you could assume the larger the mismatch, the harder it is for vibrations to travel from 1 material to the other. The impedance mismatch between steel and rubber is very large, the mismatch between steel and panzerholz is even larger.

So there are quite a few variables in play, it's a very complex model, the variables of which can produce a very different outcome for any types of objects coupled together. So we audiophiles tend to just wing it, try something, and listen if we like its effect or not.

There is no doubt physical changes occur. The debate is indeed in how it affects the sound. Where I see positive attributes in using panzerholz in high end audio applications for its rather unique properties, David has seemingly taken the stance it's a spawn of hell.

Every object is subject to resonance modes. Damping capacity or energy dissipation ability of a material affects the vibration amplitude and vibration time of resonance frequencies. Take a tuning fork as an example, the material and shape define its resonance frequency, damping affects amplitude and ring time. Now attach a piece of rubber or panzerholz to the tuning fork, the resonance frequency, resonance amplitude and ring time will change.

Now rubber or panzerholz are going to have a different effect when placed underneath a component. They both have good damping abilities but, a compliant material like rubber coupled to a mass creates a mass spring system. A mass spring system has its own resonance, when its resonance frequency is exited, it will start amplifying that frequency and starts ringing. Every material has a degree of compliance, whether its rubber, steel or panzerholz. The latter 2 are too stiff to introduce this effect to a significant enough degree.

The goal of the Daiza is not to alter the sound, it is to provide a minimal resonant surface on which to place your component. Resonance modes in Panzerholz are damped to a degree which is not available in other materials, it will hardly resonate, and it will hardly ring.

How this is all very interesting but there is more to it then just that. We have to consider how vibrational energy travels or couples from 1 object to the other. This is a highly complex model. If interested read here for an explanation of Acoustic Impedance:

https://en.wikipedia.org/wiki/Acoustic_impedance

One of the actors here is velocity of sound which is different in different materials, if we simplify the model you could assume the larger the mismatch, the harder it is for vibrations to travel from 1 material to the other. The impedance mismatch between steel and rubber is very large, the mismatch between steel and panzerholz is even larger.

So there are quite a few variables in play, it's a very complex model, the variables of which can produce a very different outcome for any types of objects coupled together. So we audiophiles tend to just wing it, try something, and listen if we like its effect or not.

There is no doubt physical changes occur. The debate is indeed in how it affects the sound. Where I see positive attributes in using panzerholz in high end audio applications for its rather unique properties, David has seemingly taken the stance it's a spawn of hell.

I sold two complete systems this weekend because of the sound in my systems, with all components/sources on Diazas.

To each his own.

I and my MANY visitors LOVE the sound of that my systems produce with Diazas installed. I have not had ONE person discuss that maybe the sound was this or that. Everyone just says it sounds amazing to the point that they pull out their wallets.

To each his own.

I and my MANY visitors LOVE the sound of that my systems produce with Diazas installed. I have not had ONE person discuss that maybe the sound was this or that. Everyone just says it sounds amazing to the point that they pull out their wallets.

Hi David,

I'm completely aware of your aversion to this technology. Yet there are several threads, I'm counting 8 in the "Vibration Control Forum", discussing the ins and outs of this, including applications for usage with turntables. So I'm not going to discuss this again.

Hi Emile,

I don’t have an aversion to the tech, I explained why it has a negative affect on turntables. None of the threads mentioned address what I wrote above rather they’re mostly about the love of tweaking. As part of one recent threads recent experience with another turntable and Stable Table by the same person was disastrous.

It doesn't, that is the point I'm trying to make. You are claiming it "kills" the sound, so I'm interested in how you think it can do that.

What it does do, measurably, and you can even confirm this by a simple "knock" test, is reduce the time a metal chassis rings after being exited. It also decreases transformer hum, reduces capacitor microphonic distortion and lowers XO phase noise sensitivity to vibration. It's effect on tubes is interesting to investigate, but I have not done that yet. I'd say we would not disagree on a very direct impact on various parts of a vinyl playback system.

Atmasphere does not seem to think chassis damping would negatively impact performance according to the post quoted below. However I'm completely open to suggestions, and time permitting, even willing to investigate.[/QUOTE]

You’re going on a tangent here, “It kills the sound” simply means it ruins the sound quality of the system as heard even in various you tube videos, the effect is much greater in real life. It seems that our argument isn’t that this platform has an affect or not but rather the affect it has on sound quality. I haven’t measured what you’re implying above and or to what extent or how evenly vibration is reduced or even if that’s something that’s even desired. What I do know is the piece of equipment was designed, voiced and left the factory based on measurements without a “tuning tweak” as you described it. The parameters you mention that are altered by this platform where taken into account while voicing the product so why attack it in this manner?

If I’m not mistaken Ralph’s thread was in context of SRA platforms and according to the designer dampening has all kinds of affect on sound quality of equipment. SRA customizes their platforms to individual electronics. I own their products as do many of my clients what I hear from their platforms and racks are completely different from a slab of panzerholz and without any of the sound destroying qualities. Not all dampening technology is the same and I doubt that Ralph meant anything goes nor do I think many, if any designer worth his title wants his products tuned by panzerholz to this extent.

david

(...) Please explain why when you transfer a digital file from one box to another over a 10cm connector the reproduced sound is affected and even drastically at times will change again using a different set of connectors and conductor yet when you open the transferred files they’re identical to the original.

(...)

Just to point that Emile explained it so well in previous posts in WBF about the Extreme that he persuaded me to buy it. In fact, he never tried to bypass my tricky questions and has given rational technical explanations on all my "bits are bits" questions.

Similar threads

- Replies

- 1

- Views

- 483

- Replies

- 1

- Views

- 138

- Locked

- Replies

- 463

- Views

- 21K

- Replies

- 0

- Views

- 233

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |