Savvas, if the noisy/vibrating motor is effectively decoupled from the arm/platter combination it will only affect the sound if you can hear it from your listening position. The Studer A 80 motor im using, is because of its shear size and friction of solid sintered bronze bearings on large steel shaft somewhat of a noise-maker, and vibrations are at certain frequencies like the putter of a Dodge Viper idlingThe ‘no character’ and ‘no sound ‘ are expressions that have been abused since long time ago

I wonder how, a ‘no character Tonearm ‘ remains with ‘no character’, if for example the tt motor is producing resonances and noise which is audible from over 2 meters away, or how a Tonearm with built-in stepper motors, industrial wires‘ management system , etc has ‘no sound‘ and ‘no character‘

This discussion in my opinion underlines the importance of measurements in manufacturing. Measurements are fundamental for the final product which is the listening.

I am not saying that bad measurements necessarily mean bad sound, but certainly they are translated into a colored sound, which can be pleasant for many. Elevated mechanical noise or resonances can negatively affect some frequencies and color pleasantly some others.

In any case the sound experience is subjective but at least with objective measurements in place , the listener will know how much colored is the sound he is getting; and will not live in an illusion of ‘no character’ or ‘no sound’

Pivoting Linear-Tracking Tonearms

- Thread starter Ron Resnick

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my friend let’s stay within OP discussion, I will PM youSavvas, if the noisy/vibrating motor is effectively decoupled from the arm/platter combination it will only affect the sound if you can hear it from your listening position. The Studer A 80 motor im using, is because of its shear size and friction of solid sintered bronze bearings on large steel shaft somewhat of a noise-maker, and vibrations are at certain frequencies like the putter of a Dodge Viper idlingBut the sound is phenomenal ! And vibrations and noise can not be heard at my listening position, or with needle in the groove with ear close to the speakers. Only one time where i had inadvertently let the phono cable touch the test motor housing did it translate into noise from the speakers.

I think the concept of "no sound from a tonearm" does not advance our intellectual or analytical understanding of the matter.

Let's say I am at audioquattr's house and we are comparing the SME 3012R to the Reed 5T. Both tonearms are mounted on a single Air Force 3 Premium. On each tonearm is mounted a vdH Master Signature cartridge.

From the 3012R combination we hear deeper and more dynamic low frequency information. Kickdrums are more dynamic, more powerful and higher in resolution.

From the 5T combination we hear a more feathery airiness on vocals, and high frequencies somehow seem more delicate. The 5T does not reproduce low frequency power or weight the way the 3012R does.

How does the concept of "no sound" apply to these subject comparative listening impressions? Subjectively, the cartridge/tonearm combinations sound a little bit different.

Is the 3012R creating more bass impact, thus violating the "no sound" criteria?

Is the ethereal airiness of the 5T the result of the 5T adding something to the sound or subtracting something from the sound? How does "no sound" apply to this impression?

These rhetorical questions suggest to me that the concept of "no sound" doesn't help us understand tonearms. In much the same way that words are useful mainly or only to the extent they help us to distinguish certain things from other things, how can we describe the different sonic impressions we have from different tonearms If we start with the axiom that tonearms should have "no sound"?

I have the Thales and the 3012R.

On the TW Acustik AC-3 the Thales is the better sounding tonearm in my system. It's more dynamic, faster and overall just seems to be more pure sounding across the entire record.

The 3012-R has a nice laid back sound, is maybe a little more open sounding on top but bass control is not as good. That said, the 3012-R is very good and sounds a lot better than my Graham Phantom.

Last edited:

Hi Ron - i have the 5A with a Miyajima Destiny and Crystal Absolute Dream tonearm cable - i think you would like it as it ticks all my boxes and sounds great. Cant answer your other questions.

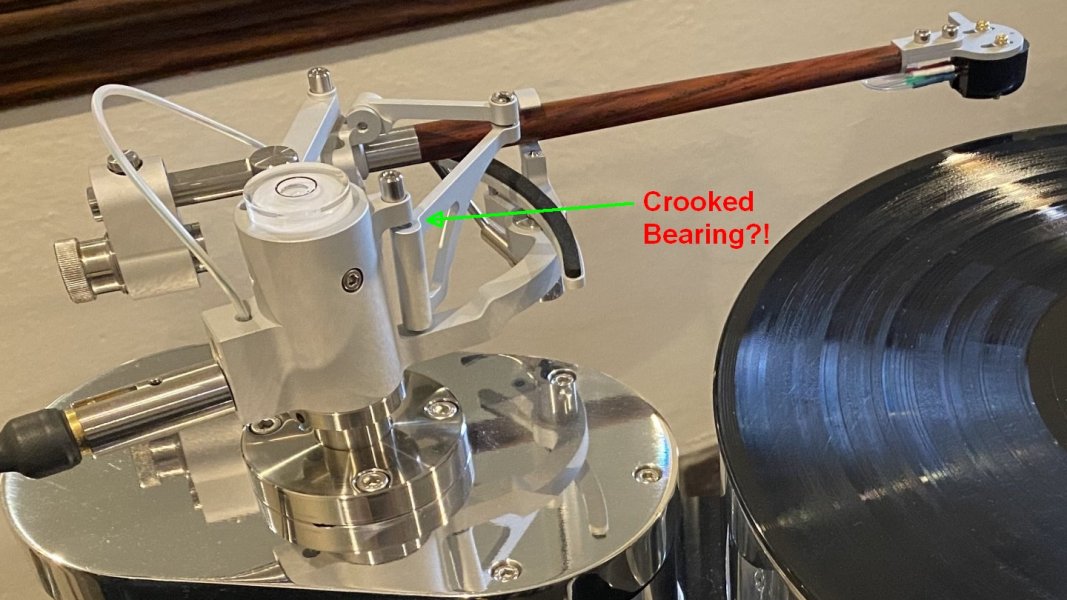

Based on your picture of the Reed 5A tonearm. The bearing on the guiding mechanism looks crooked. Am I seeing it right? All the other pictures from the Reed website, it looks straight.

Attachments

Hi Ron - i have the 5A with a Miyajima Destiny and Crystal Absolute Dream tonearm cable - i think you would like it as it ticks all my boxes and sounds great. Cant answer your other questions.View attachment 72188

It looks great!

Reed offers a few different metal finish options, including:

Seashell White

Ruthenium Glossy

Palladium Satin

Which particular Reed metal finish is on your tonearm?

I have just received a 5A today have not opened the box yet

EXCELLENT Mik!

(By the way, have you ever heard the Reed 5T?)

Hi Ron,

Mik has the 5T set up permanently on demo and uses on various TTs.

It would be absolutely amazing to read a sonic comparison between the 5A and the 5T on an apples-to-apples basis! That would be original, groundbreaking research!

Last edited:

It would be absolutely amazing to read a sonic comparison between the 5A and the 5T in an apples-to-apples basis!

I am sure Mik can do that for you if you ask him.

Ron, you always stressed to me your deep reticence to deal with/buy from, boutique/small scale output/minimal provenance products. You know, the guys I love to buy from Lol.

So, why Reed? Or more critically, why not not Reed?

There are exceptions to (almost) every rule. For me, Vintage Audio Specialties is one such exception.

Reed seems to make very high-quality products. The fit and finish of the 5T appeared to be top-notch. Michael Fremer reported the same in his review of the 5T.

The question for me with something like a Reed tonearm is whether there is an expert Reed tonearm installer somewhere on the West Coast, or, at least, somewhere in the USA.

Last edited:

There are exceptions to (almost) every rule. For me, Vintage Audio Specialties is one such exception.

Reed seems to make very high-quality products. The fit and finish of the 5T was top-notch.

The question for me with something like a Reed tonearm is whether there is a Reed tonearm expert installer somewhere on the West Coast, or, at least, somewhere in the USA.

I also have my eye on the 5A and 5T Ron. Mik did say the 5T took a fair bit of fettling to get it singing but once dialled in, it was lovely.

Ron, I've surpassed even myself w recent tonearm...it's a Russian/Finnish/NZ/US/Aus joint venture Lol, based on 100% British original design.There are exceptions to (almost) every rule. For me, Vintage Audio Specialties is one such exception.

Reed seems to make very high-quality products. The fit and finish of the 5T appeared to be top-notch. Michael Fremer reported the same in his review of the 5T.

The question for me with something like a Reed tonearm is whether there is a Reed tonearm expert installer somewhere on the West Coast, or, at least, somewhere in the USA.

Does it have a name?Ron, I've surpassed even myself w recent tonearm...it's a Russian/Finnish/NZ/US/Aus joint venture Lol, based on 100% British original design.

EXCELLENT Mik!

(By the way, have you ever heard the Reed 5T?)

I have 3 5T tonearms I actually find them extremely good value for money they take a bit of tweaking so takes a little while to get the best out of them also seem very sensitive to arm board material change. Optimally set up its an incredible tonearm with a sense of air and space that is breathtaking with a great sense of speed the most interesting thing is the midrange can be very grain free and very natural. It is rather fussy with cartridge matching. If not used correctly can sound pretty uninteresting I think the tonearm is a marvellous creation overall and one of the few products where value for money as per build engineering and sound seems to be very balanced. I won't be playing the 5a for a while as there are quite a few arms to be played first.

I have 3 5T tonearms I actually find them extremely good value for money they take a bit of tweaking so takes a little while to get the best out of them also seem very sensitive to arm board material change. Optimally set up its an incredible tonearm with a sense of air and space that is breathtaking with a great sense of speed the most interesting thing is the midrange can be very grain free and very natural. It is rather fussy with cartridge matching. If not used correctly can sound pretty uninteresting I think the tonearm is a marvellous creation overall and one of the few products where value for money as per build engineering and sound seems to be very balanced. I won't be playing the 5a for a while as there are quite a few arms to be played first.

Thank you very much, Mik, for this extremely interesting report!

From a Grado Epoch3 on the Reed 5T I heard an ethereal, airy quality on vocals which I have been unable to get out of my mind ever since! The sonic magic I heard from that combination compels me to explore the 5A, and to explore further the 5T.

Which cartridges did you find to be the best matches for the 5T?

Does the 5T take up any more space on a turntable plinth than a conventional pivoting tonearm? (I have to figure out if the American Sound AS-2000 can accommodate the Bergmann Odin and an SME 3012R, as well as the broad wingspan 5T.)

Last edited:

Thank you very much, Mik, for this extremely interesting report!

From a Grado Epoch3 on the Reed 5T I heard an ethereal, airy quality on vocals which I have been unable to get out of my mind ever since! The sonic magic I heard from that combination compels me to explore the 5A, and to explore further the 5T.

Which cartridges did you find to be the best matches for the 5T?

Does the 5T take up any more space on a turntable plinth than a conventional pivoting tonearm? (I have to figure out if the American Sound AS-2000 can accommodate the Bergmann Odin and an SME 3012R, as well as the broad wingspan 5T.)

Hi Ron,

That ethereal airy quality is typically the domain of linear tracking - I think you’ll find that your new Odin will do this in abundance too. My previous (inferior) Bergmann arm did similar. The Vyger arm also did airy and ethereal very well. The Vyger was somewhat unique in also having great weight too. Whether that is the TT itself giving that we will never know since Vyger don’t typically sell their arms separately.

The Vyger has to be seen as a package generally the arm is also quite big and not easy to mount on every turntable. The reed 5t is very different to the odin it has a blackness to the performance a real sense of transparency that is very grainless the only problem it has sound dull and boring if not handled with care. While the odin injects its own bit of life.

The Vyger has to be seen as a package generally the arm is also quite big and not easy to mount on every turntable. The reed 5t is very different to the odin it has a blackness to the performance a real sense of transparency that is very grainless the only problem it has sound dull and boring if not handled with care. While the odin injects its own bit of life.

Mik - does the 5T have powerful and deep bass like the best pivots or is it shy like some LTs can be?

Similar threads

- Replies

- 67

- Views

- 15K

- Replies

- 13

- Views

- 7K

- Replies

- 5

- Views

- 6K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |