Mark Seaton wrote:

Hi Ron,

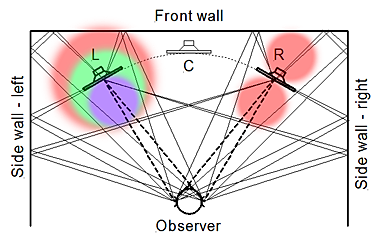

One key difference with your speakers vs Mike's are that the ribbon and AMT columns are both dipoles. Dipoles have a cancellation/reduction in output in the plane of the speaker's face with the sound radiating in a pattern that would look like a figure 8 if observed overhead. Here is an over simplification of the situation:

Here you can find some great info regarding dipole speaker operation and listening rooms from one of the experts on the matter, Siegfried Linkwitz. It is admittedly heavy on the math and a very technical approach to the issues at hand. Here is another great graphic I found from Linkwitz showing how reality deviates from theory with different types of dipole implementations:

For a better understanding of dipoles scan through this page from Linkwitz as well where I pulled this image which clarifies many of the differences between conventional, front firing speakers vs dipoles when set up in the room:

The point here is that the speaker's dipole operation above ~250Hz means there isn't much of an early lateral reflection for the woofer towers to block. Also important is that for the listening distance I suspect you will be at, the first side wall reflection will be well forward of the area shadowed by the woofer tower.

Could you give us a general recap of the size and openings to the space you are setting up in?

The "room" is a dedicated space -- 19.5' wide X 24.5' long X 14.5' high (except for an asymmetrical ceiling soffit at 9.5' that steps down above the left rear side of the room) -- but not really a dedicated room. One-third of the left side of the space (towards the rear wall) is open to the kitchen, and one-third of the right side of the space (towards the rear wall) is open to the equipment room.

The front wall is poured concrete. Right now over the front wall a sheet of drywall has been erratically glued directly to the concrete, leaving some areas of the drywall sounding solid and some areas sounding hollow when rapped with knuckles. There is no insulation in the walls, so I think I have to have all of the drywall taken off to expose the concrete areas and the wood-framed areas.

The first third of each side wall from the front wall is cinder block. So imagine the first third of a rectangular with a short side as the front wall -- the front wall is concrete and the first third of the connected parts of the side walls are cinder block. The remaining two-thirds of each side wall is either regular wood framing or open space (either to the kitchen on the left or to the equipment room on the right).

Today I researched:

1) mass-loaded vinyl

2) NoiseOut2 (Bonnie's version of mass-loaded vinyl)

3) resilient channel construction

4) Green Glue

5) Quietrock

Green Glue works as a visco-elastic layer between two sheets of drywall. Green Glue can be used to glue sheetrock to another layer of sheetrock (or to a hard wall surface, I believe).

Quietrock is a constrained damping product. It needs to not be attached directly to concrete or plaster because its method of operation requires it to be able to vibrate and dissipate vibration into heat, which it cannot do if it cannot move. Quietrock should be glued or screwed or both to wood framing or can form the outer layer of a resilient channel arrangement.

So, I can use Green Glue to glue regular drywall to the concrete walls, but I cannot use Green Glue with Quietrock on the concrete walls. I can use Quietrock on the wood framing, but I would rather not fir out the concrete walls with wood framing to hold the Quietrock because I would rather not haircut the room dimensions on three sides for no reason.

Yet, I assume that it is desirable to use the

same wall surface material all around rather than having regular drywall on the concrete portions and Quietrock over the wood framing portions. I assume (but I do not know) that it cannot be good for the first third of the left side wall and the right side wall from the front wall to be regular drywall and the remaining two-thirds of the side walls to be Quietrock -- or should I not be concerned about that slightly dissimilar material?

I think all of the drywall has to come off of the wood-framed portions so the open areas in the framing can be filled with blue jeans insulation.

Right now I am inclined to use Quietrock all around, gluing it to the concrete sections with Green Glue, which should provide a bit of the flexibility Quietrock requires, and then screw and glue Quietrock on all of the wood-framed areas.

That leaves the slightly dropped drywall ceiling. Do I take all of the drywall of the ceiling and make sure the framing crevices are filled with blue jeans insulation and then install Quietrock?

Does this make sense?

What is your advice?