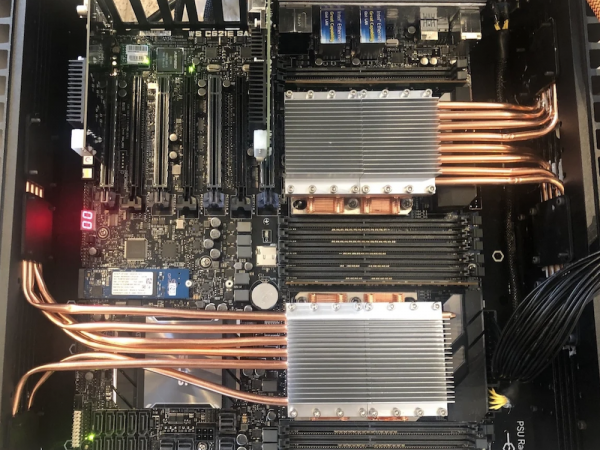

FWIW, I bought four HDPlex chassis just to take their cooling kits to do the DIY passive cooling for my dual Xeon CPUs. That's $1,192.

- Then I bought 2 Dynatron heatsinks for $100.

- Thermal epoxy for $80.

- 13 good quality heat pipes for $150.

- A pipe bending tool for $20.

- Then two more heat pipes for $30 because I broke two.

Total: over $1500 just to get the passive CPU cooling.

And it looks ugly, nothing like the elegant solution on the Extreme.

View attachment 68432

(sorry for the old picture, it's not the final version)

More info here:

https://audiophilestyle.com/forums/...-server/page/14/?tab=comments#comment-1047952

Oh, wait, that's not all. I was doing research and planning almost every night until 2-3 am for about 3 weeks until I came up with that. It may look simple, but I looked at every available commercial cooling solution for LGA 3647 sockets. I also had to do some extensive reading about heat pipes, thermal properties of materials, thermal epoxy, etc. My head was spinning for a while!

After spending that much time and money, I had no idea if it would even work. Once you apply the thermal epoxy there is no going back! I was prepared to scrap everything and start from scratch. But I was lucky, and it worked great despite the way it looks. And I have been enjoying it for 5 months.

If I was to start this all over again and someone offered me the Taiko cooling solution for $1500 or less, it would be a no brainer.