Hello ianm0,

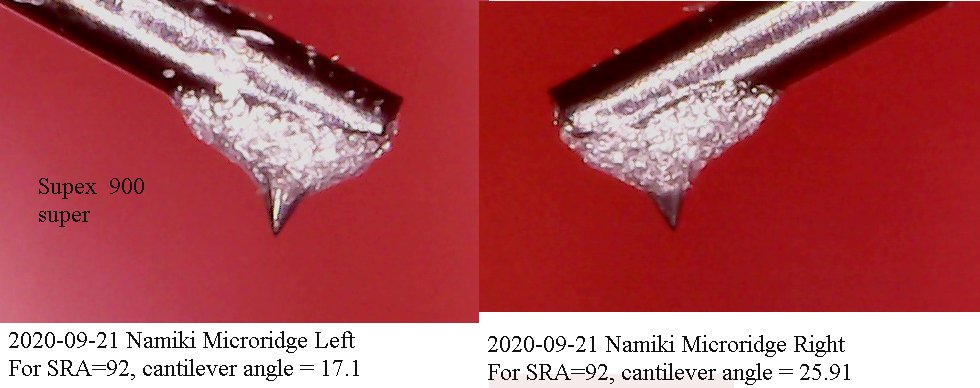

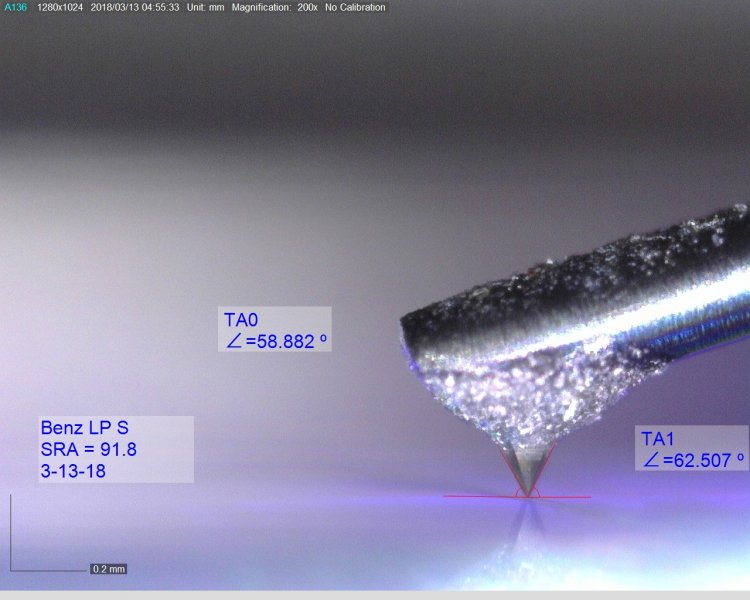

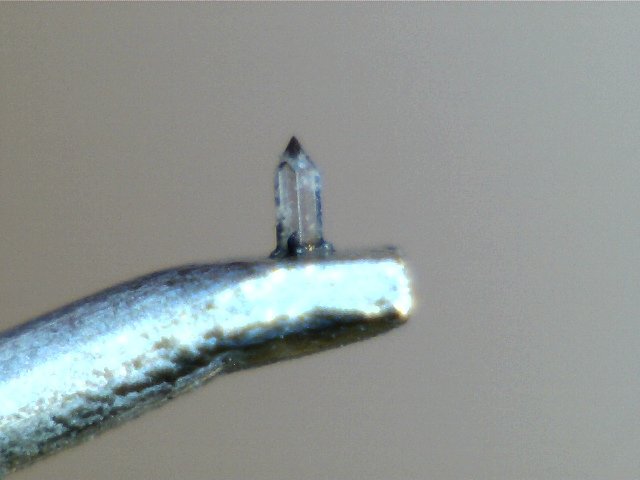

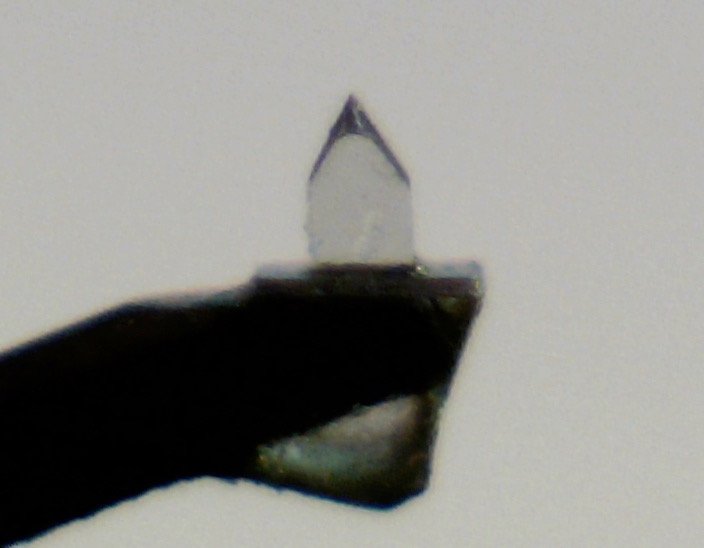

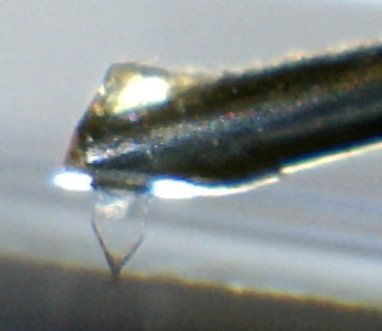

This approach could work but it still does not take the requirement away of having to get a really good view of the stylus to take your measurement. I generally make my measurements at up to 450x magnification because that way I don't have to "hope" that the contact edges of the stylus are in the center of the shank. If you have a Shibata, SoundSmith optimized line contact stylus or some other unique design, there is no way you can use ~200x to get an accurate angle.

You are definitely correct that you need to take the photograph with perpendicularity to the cantilever (I am working on the WallySRA tool that addresses these issues). See this link for more on your point on the need for taking your photo properly:

https://www.analogplanet.com/content/another-angle-digital-can-worms.

However, your approach doesn't offer you any freedom from the requirement on the INITIAL photographs you have to take to establish the relationship between the stylus and the cantilever. Once you know that angle, then you are "free" to use the cantilever angle to set SRA once the calculations are done.

One more thing: add between 0.25 and 0.45 degrees to your target cantilever angle to account for the impact on SRA by stylus drag.

It is interesting to know how sensitive SRA is to compression under VTF: Assuming a 6mm stylus tip to cantilever pivot point dimension, a TINY 0.15mm change in cartridge height will cause a relatively large 1.4 degree change in VTA/SRA. Depending upon the compliance of the cartridge, you could get a 0.15mm change quite easily from adding as little as 0.3 grams of VTF to your current setting.

Since cantilever deflection is NOT a linear function (impedance increases as deflection is increased), you CANNOT use VTF as a function (in addition to changes in cartridge height before and after application of VTF) to derive an SRA from a photo and data like the one you have posted. I'm not saying you were suggesting this, but someone might just wonder...