Application: Interior use, new wood, Baltic Birch Plywood with exposed edges.

Availability: First off I don't even know if I can get real varnish any more (Carver-Tripp is gone). All the stuff on the shelves looks like the exterior marine grade with UV protectant added. Special order for interior grade stuff, wait a week or do a couple hours of driving and burn some gas.

Why I like Varnish: gives wood a honey glow, some call it amber.

Why I don't like Varnish: the honey glow goes away after a few years, and the wood looks lighter, bleached out. Some call say it clouds. Also it may have a longer drying time.

...............................................

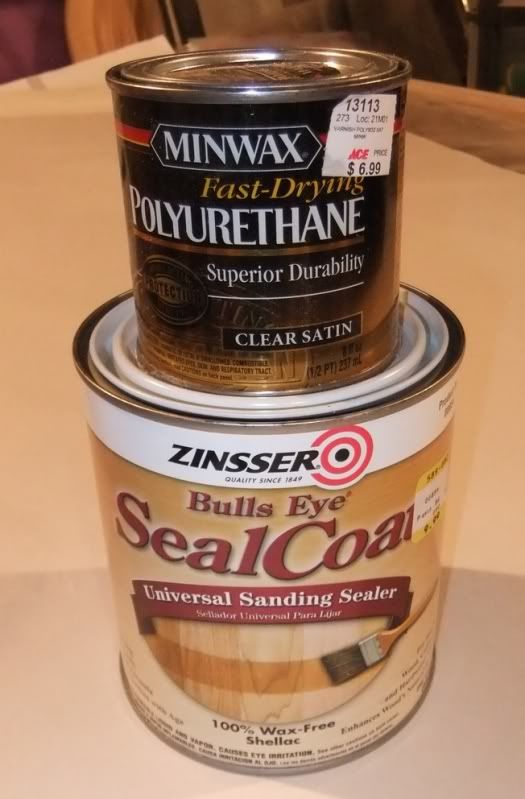

Why I like Polyurethane: I can get MinWax clear satin anywhere, anytime. It is supposed to be more stable color wise than Varnish and more durable.

Why I don't like Polyurethane: it gives wood a reddish hue (oil based stuff does this) and looks flat, dry or dead when compared to varnish (even the glossy does not have the same depth of sheen). It's plastic, right? Now your wood looks plastic or fake, and it feels different than varnish. Varnish has a natural smoothness, Polyurethane is more rubbery, not as hard shell like (guess it may not scratch or chip as easily?).

.............................................

I'm looking to hear from die hard fans of varnish.

I'm looking to hear from the converts who now swear by oil based polyurethane.

I'm looking to hear from those who have gone green and trust the water-born alternatives.

Old varnish/plywood project:

Availability: First off I don't even know if I can get real varnish any more (Carver-Tripp is gone). All the stuff on the shelves looks like the exterior marine grade with UV protectant added. Special order for interior grade stuff, wait a week or do a couple hours of driving and burn some gas.

Why I like Varnish: gives wood a honey glow, some call it amber.

Why I don't like Varnish: the honey glow goes away after a few years, and the wood looks lighter, bleached out. Some call say it clouds. Also it may have a longer drying time.

...............................................

Why I like Polyurethane: I can get MinWax clear satin anywhere, anytime. It is supposed to be more stable color wise than Varnish and more durable.

Why I don't like Polyurethane: it gives wood a reddish hue (oil based stuff does this) and looks flat, dry or dead when compared to varnish (even the glossy does not have the same depth of sheen). It's plastic, right? Now your wood looks plastic or fake, and it feels different than varnish. Varnish has a natural smoothness, Polyurethane is more rubbery, not as hard shell like (guess it may not scratch or chip as easily?).

.............................................

I'm looking to hear from die hard fans of varnish.

I'm looking to hear from the converts who now swear by oil based polyurethane.

I'm looking to hear from those who have gone green and trust the water-born alternatives.

Old varnish/plywood project: