So I got busy today and tried some things out. I disassembled one of my speakers so I could get the 18" woofer out of it and installed it in the prototype bass cabinet, which I fortunately still have. I've been trying to get rid of it thinking I'd never have any use for it. It's pretty much the same as the others.Tim

I am impressed with your detective work !

I recall you measured at the mouth of horns and there was no dip so it's getting into the space

If there is no bass in adjacent spaces then i suspect its a wall or window acting as a membrane absorber .. it would need to be a large area to have such a comprehensive effect

That is the thing you cant accurately calculate in a design as the wall systems are not all precisely the same

Of course I am making assumptions based on a small amount of knowledge so ... ???

Would it be too crazy to measure on the other side of wall or window to see if there is a 85 Hz peak

Phil

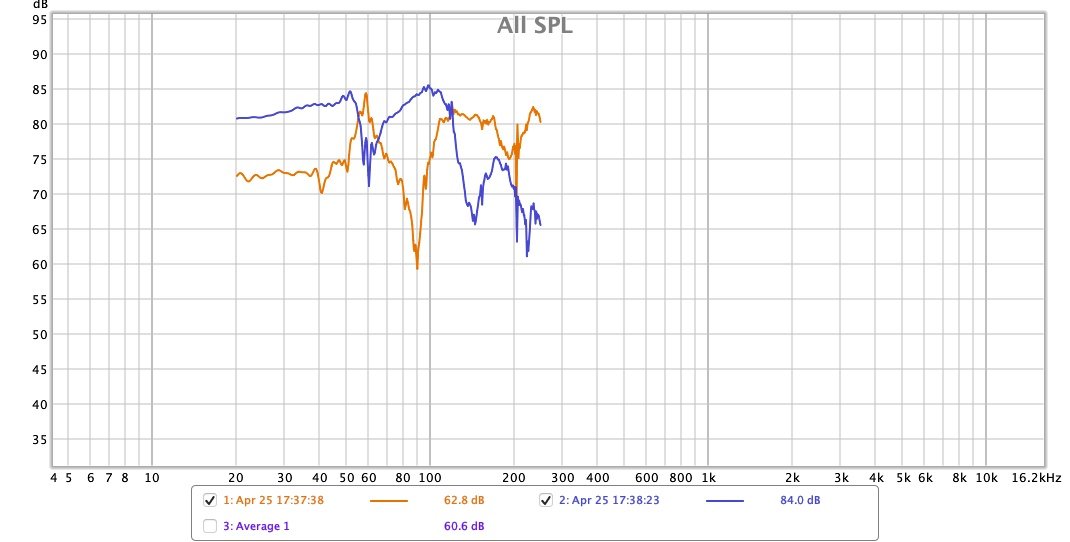

On the prototype, I drilled a hole right above the throat so I could drop the mic in and measure there, right in front of the driver. I measured on the other side of the driver in the back chamber too. Looking at the chart, the blue line is the back chamber response and the orange is the throat. It's pretty clear what's happening. The mouth termination is too small for the length horn so an inverse polarity back wave travels back to the throat and arrives just in time to be out of phase with the driver at that frequency. The driver is definitely moving as can be seen from the back chamber pressure. It's just got no impedance match on the front side so it's highly inefficient at that frequency - about 89 Hz with this horn. Down at 60Hz the opposite is happening. The back wave from the mouth is increasing pressure in coordination with the driver moving forward, increasing its impedance match and actually reducing its motion while simultaneously increasing output from the horn, so the back chamber level goes down. With this single cabinet operating by itself and not in a corner it shows the problems very clearly. Stacking the woofers together in the corner helps them out quite a bit but not enough to fix the 85 hz issue. It actually makes the Q higher so the notch is narrower and deeper. I think this is because vertically the horn mouths are big enough, but horizontally they are not.

Earlier I said there was no dip inside the horn mouth but that's not really true. There is a dip but everything is louder in there so I can clearly hear the missing frequency. I didn't realize how much louder other frequencies sounded until I stuck my head in there at those frequencies. On measuring, the dip is not as severe just inside the mouth as it is at the throat so some interesting things are happening along the length of the horn, but overall the total sound energy being produce at that frequency is much lower.

Edit - I removed a screen so I could put the microphone at various distances along the inside of the horn. There's a huge peak at 79 Hz inside the horn. It's not a huge peak in the room, but a filler between the null at 85 Hz and the smaller null at 75 Hz.

Edit: The following paragraphs are conjecture that may not be correct.

So that's why I couldn't find 85 Hz anywhere in the room. It isn't a room cancellation issue - it's an impedance matching issue actually reducing the sound power output from the horn. It goes to show that air displacement is not always proportional to sound power output. The air has to get squeezed, not just sloshed around. Drivers move much slower than the speed of sound so the air has to get trapped at least a little to make any sound at all.

I've always kidded that direct radiator woofers are air sloshers, because at 1 or 2 percent efficiency that's mostly what they are doing. They do manage to get enough squeezing in to make great bass if they are big enough and/or have enough power and excursion capacity. With my horns, at 85 Hz the joke is on me! I'm sloshing air like it's nobody's business!

I tried some remedies - stuffing the back chamber with poly fill, stuffing the throat with poly fill, putting a cushion in the mouth. Poly fill did very little. The cushion in the mouth actually broadened the cutout zone. Not quite as deep but much broader. As usual, damping with absorption means reduced efficiency. One possible solution is to continue the horn flare gradually so that the mouth is much bigger. That means a much bigger horn. Another possibility is to put a V shaped midrange line array horn in front of the bass horn mouths. That would ease the pressure change and reduce the cancellation. Once again the speaker gets bigger.

Finally, I could just build faceplates to go in the mouths and put the drivers up there. Then I'd have direct radiators.

Attachments

Last edited: