You need this:How do you roll tape around the spindle and keep the same distance from spindle as each time you wrap the tape, invariably an unequal deviation of distance will occur from the spindle to various points of the template. It won’t be perfect, at least the way I envision wrapping the spindle with tape, and not removing the platter. The SME V templates that came with my V Arms were always loose with the spindles and was also an issue and SME never provided any directions as to how to cinch the spindle or template holes to make them snug. I guess if you get it done correctly then you can use it. However, the Wally tool is fairly straightforward as well and you can use the mirror to align the cartridge. That is what it I have been using for a while now.

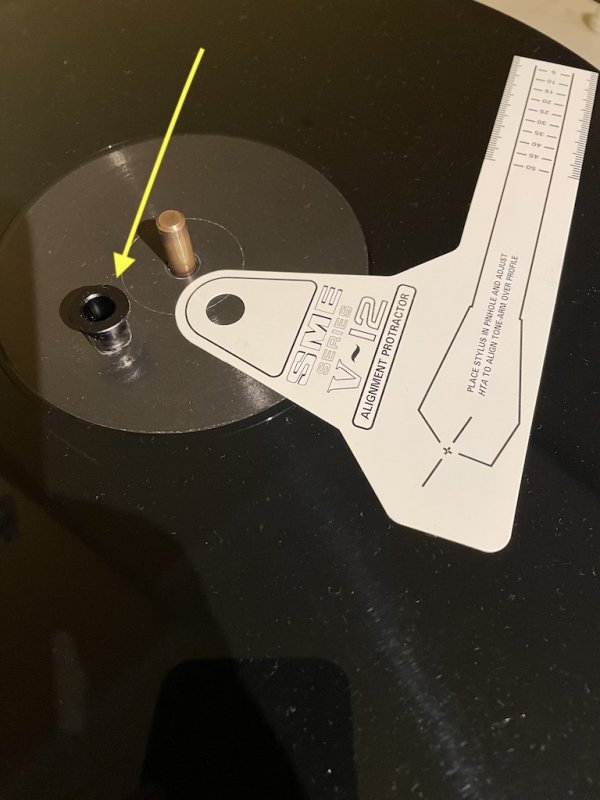

if you want a snug fit and better precision you can roll tape around the spindle like this but you don't have to:

Additionally you can do the same to spindle bush's lower, wider part. Just one turn made carefully and equally is enough. This way you can achieve better precision than any other protractor cause none of them snugly fits the spindle.

That's great.J.R came to the house and spot checked my alignment and he was impressed. So, if I can do it, so can anyone else. It’s part of the toolbag.

Last edited: