Folsom, a couple of days ago you where commenting on the potential inaccuracies of the Roadrunner, with some silly unrealistic example. And got schooled by the designerIf you think that is strange, then I will say from the engineering side we think people that run before walking, and that tell us about their theories on engineering are much stranger.

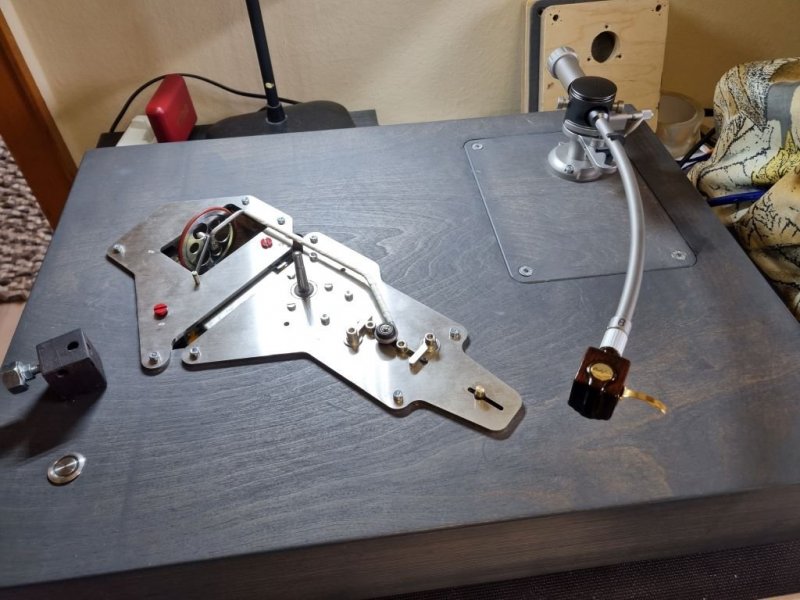

While I ultimately will often use other's products for different things, inexperience with them isn't always inexperience with equivalents. We have various power supplies, ways to generate signals, etc. But no desire to leave a stereo in lab hooked up like Frankenstein. Just like I said to Microstrip, I think it's a bit silly to use variac for stereo, but we use variac all the time for testing. So that's why I'm interested in other makers' stuff. There is only so much time in the day, and we've got enough R&D backslated that could use more time of day between other things as is. We find no need to reinvent anything with turntable motors yet.

Lagonda is confusing things. The only argument he has is that he believes ultimate speed is an appreciable factor. I'm saying I cannot find anything to substantiate that, only the type of power delivery with the intended engineered speed. For whatever reason he goes on to say I think it's all fooey when I am saying exact opposite as conclusion of playing with motors, collective research, and personal experience listening.

„Just not note it's not necessarily fun or easy to adjust for voltage. In these applications it could mean swapping transformers, unless maybe using the Road Runner has adjustable output voltage? The wattage is high pretty high for doing that.“

Showing a misunderstanding of what the Roadrunner does, you where alluding to the accompanying power supply of course, honest mistake

Then you presented this little beauty of an argument:

“ Truth is turntable speed is similar to subwoofers... The control you can exert electrically is limited before it causes as much of a problem or more that you're trying to correct.“

I’m leaving the subwoofer part alone for today. You assume that because you have not been successful at this endeavor, Phoenix Engineering has not managed the task either ?