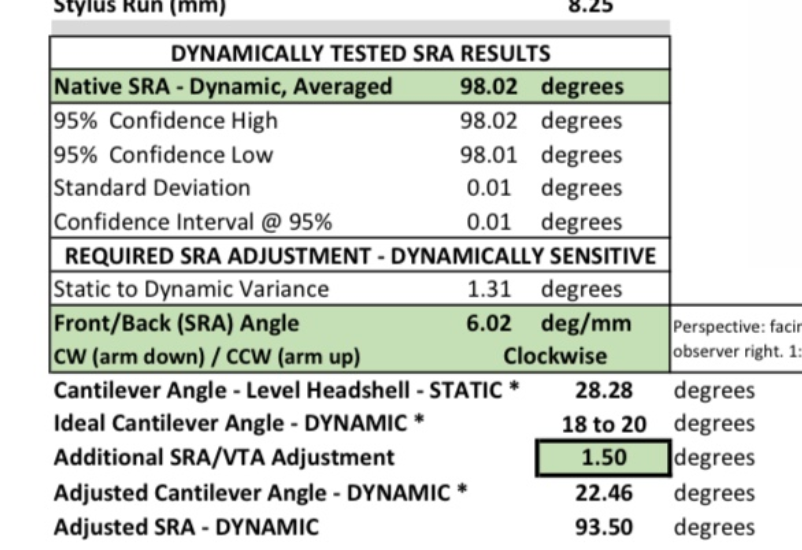

This is really beautiful. The human eye is far more sensitive to vernier acuity than spatial acuity! The problem however, is that even if you think you can assess this accurately, it does not necessarily translate well to what is really important, which is the stylus rake angle. For that you have to know precisely how the stylus is mounted in the the cantilever!! You may think that that by getting the front of the cartridge perfectly perpendicular to the record, that your SRA will be perfect (approximately 92 degrees). But that is simply not true. The stylus can be mounted leaning further forward or backward in the cantilever so that an ideal adjustment may require raising or lower the rear of the arm accordingly. For example. take a look at post #8 on this thread in which Ron had is cartridge analyzed by JR Boisclair at Wally tools:

I feel strongly that without optimal cartridge alignment and proper turntable set-up and ideal speaker positioning audiophiles are not capitalizing upon the sound quality of which their components are capable. One of the well-known, but not often talked about, perils of this hobby is the...

www.whatsbestforum.com

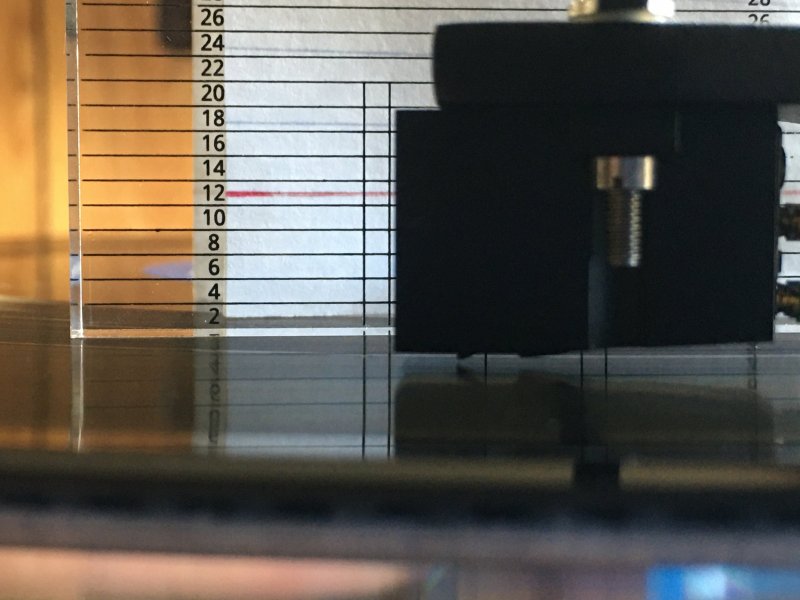

View attachment 97467

In short, the only way you can be assured of getting your SRA right is to set it either by ear (raising and lowering the arm and ignoring perpendicularity, which means nothing) or, if you want the top of the cartridge (hence arm) to be perfectly parallel with the record surface, you need to use a shim to correct for how your particular stylus is mounted in your cartridge using a service such as Wally tools. As an FYI, it took me years to understand this! Even after reading Fremer's writings on this for what seems like forever, I really didn't understand it in tangible terms, until I heard JR give a lecture on the subject at AXPONA this past spring!