I get what you are saying, and agree all parameters should be on a tight tolerance for high end carts. That said nothing is perfect and there is always a tolerance for all tangible objects...even if very fine. So we adjust.I don't think the question is whether the ear is better than measurement tools. Rather, you can't do anything about an imprecise zenith alignment unless you know you have one. Do you know if you do or do not?

No issues regarding manufacturing QC. It's inexcusable when you are paying 10K + for a cartridge not to be assured the zenith is spot on.

How do we know if the azimuth is off by a fraction of a degree in the way the stylus is mounted to the cantilever? We either listen and adjust or measure and adjust. How is zenith different? Never mind the debate over tracing distortion 'value' versus other parameters...

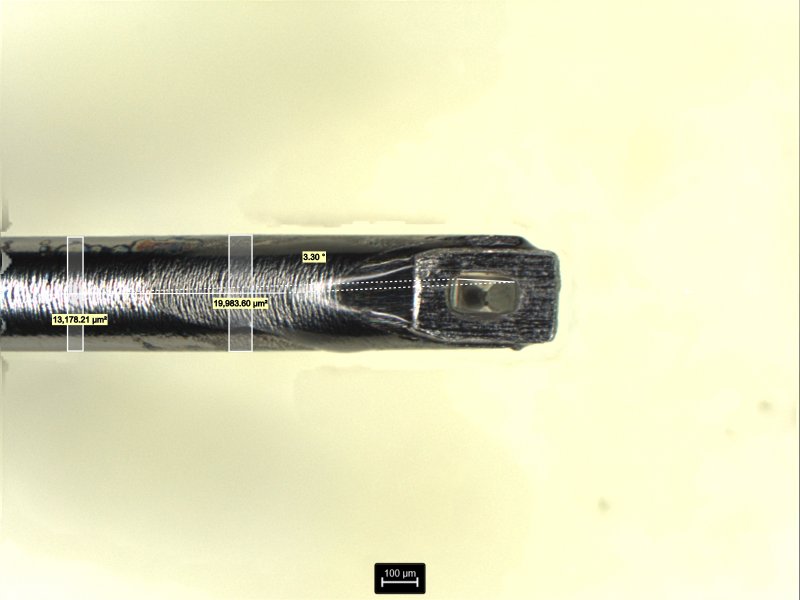

When manually aligning a cart ( to lofgren etc ) we are setting 'macro zenith'...just hoping to use a bigger visual cue ( cantilever ). The better our magnification and light the more we can attempt to use the stylus for this. Having a microscope analysis of the zenith is imo a helpful bit of info.