check the Analogmagik and Adjust + threads???? Perhaps an actual pointer will help..

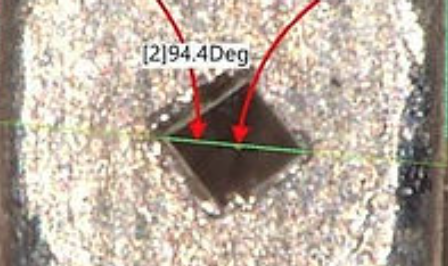

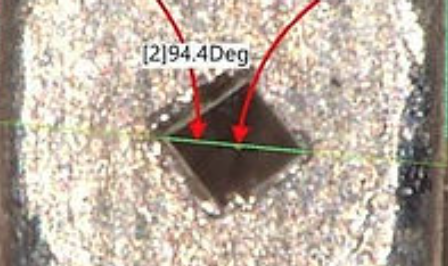

The importance of VTA, SRA and Azimuth - pics

- Thread starter ack

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I don't recall seeing Zenith in AM? Is this the newer version??I’m using Analogmagik program to correctly align zenith too.

Dear J.R.Hi @airbearing. When changing the size of the contact surface of the stylus by means of altering its azimuth angle, all you are doing is changing the surface area (MAYBE) but applying the same force to that new area. In other words, a one inch cube that has a mass of 1 gram applies the SAME force against its resting surface as a half-inch cube that also weighs 1 gram. The change in size of the object does not change the APPLIED force. It only changes the force over a fixed surface area. Since applied force did not change, skating force will not change.

Further, coefficient of friction is independent of surface area except when the surface area gets too small and begins digging into the material. One could argue that vinyl deflection is greater with smaller surface area but I am not aware of any studies that have shown that this effect is great enough under NORMAL PLAYBACK CONDITIONS to affect skating force.

you need to take into account the breakdown torque and the statical pressure on the groove edge.

support pressure is a dynamical pressure.

best

E.

www.AudioCirc.com

no, but you can use vta track to adjust zenith. it's a confirmed method by owner and creator of program.I don't recall seeing Zenith in AM? Is this the newer version??

The VTA track is going to be very sensitive to zenith alignment. If zenith is misaligned, you'll probably see VTA distortion measurements higher than 3%. It's easy to measure higher than 10%, even. My Opus 1 measured less than 2% left and right on the VTA track after I iterated on zenith. Don't forget to recheck overhang, though.I don't recall seeing Zenith in AM? Is this the newer version??

Besides using AM test record I double check alignments with Analog productions test record too. Vta, azimuth and antiskating are all located different radius on those test records. Which is a proof that I seek when aligning zenith with vta track other than listening.

Vta track is located close to spindle on AP test record and close to beginning of the record on AM, but both tracks lead me to the same sweet spot on zenith alignment. Same thing happens with antiskating too. On azimuth if you have a vacuum hold down turntable again both records lead to the same alignment. if not than record flatness playing a major role on end results.

This is a clear indication for me that AM is working.

Generally AP test record is better for azimuth. On the other hand it has inconsistent/unreliable speed track. I prefer AM speed track. AM test record was cut at a lathe with better speed consistency and low wow&flutter compared to AP test record. When I check the test signals of both test records on FFT analysis I assume that AM used digitally created test signals and AP used analog. it’s just a guess you can not be sure.

Vta track is located close to spindle on AP test record and close to beginning of the record on AM, but both tracks lead me to the same sweet spot on zenith alignment. Same thing happens with antiskating too. On azimuth if you have a vacuum hold down turntable again both records lead to the same alignment. if not than record flatness playing a major role on end results.

This is a clear indication for me that AM is working.

Generally AP test record is better for azimuth. On the other hand it has inconsistent/unreliable speed track. I prefer AM speed track. AM test record was cut at a lathe with better speed consistency and low wow&flutter compared to AP test record. When I check the test signals of both test records on FFT analysis I assume that AM used digitally created test signals and AP used analog. it’s just a guess you can not be sure.

Last edited:

Hi @airbearing. Perhaps we'll have to agree to disagree. I am not saying that there aren't other factors that influence anti-skating (as seems to be your point). I am only saying that those factors are so infinitesimal compared to the greater "compromise of averages" that we have to use when applying anti-skating in the first place that it doesn't provide benefit to account for those factors. There is a point where the improvements in our formulas begin to approach the "noise floor" that any randomized, normal distribution of standard variables would exhibit.Dear J.R.

you need to take into account the breakdown torque and the statical pressure on the groove edge.

support pressure is a dynamical pressure.

best

E.

www.AudioCirc.com

Ha ha J.R., you are playing down a little the impacts of all these factors. They are definitely here (!).

In my eyes it is somehow funny that we have listened to music in the past 60 years quite well only to hear now that we forgot to control and correct the Zenith.

Anyway I wish you the best in your activities.

E.

www.AudioCirc.com

In my eyes it is somehow funny that we have listened to music in the past 60 years quite well only to hear now that we forgot to control and correct the Zenith.

Anyway I wish you the best in your activities.

E.

www.AudioCirc.com

I’m happy to put it to the definitive test. I will add stylus azimuth angle as a factor in our coefficient of friction tests that we plan to run before the year is out. We will measure the results on various stylus profiles with plus/minus 1.5 or 2 degrees of change. If it is a less than negligible phenomenon it will be captured in the results. Sound good?Ha ha J.R., you are playing down a little the impacts of all these factors. They are definitely here (!).

In my eyes it is somehow funny that we have listened to music in the past 60 years quite well only to hear now that we forgot to control and correct the Zenith.

Anyway I wish you the best in your activities.

E.

www.AudioCirc.com

I think the reason that zenith hasn’t been given much attention may be twofold: firstly, it is difficult to measure, but probably more likely that it hasn’t gotten much press is because fine line contact styli were not commonly available until a couple decades ago. By the time they were everywhere, almost no scientific research was being produced and published on vinyl playback that would have brought attention to this. Manufacturers knew that their stylus/cantilever assembly vendors had loose tolerances, had no way to measure zenith on their own and were not about to publicize the fact that the emperor had no clothes.

Lastly, the community had gotten so used to living with the pinch effect that is so characteristic of conical and elliptical profiles that they may have not noticed they now had a way to avoid it altogether with fine line contact styli.

Just a guess!

Lastly, the community had gotten so used to living with the pinch effect that is so characteristic of conical and elliptical profiles that they may have not noticed they now had a way to avoid it altogether with fine line contact styli.

I think this is an interesting concept when you get to mono where conicals seem to "rule the roost". My problem with the "pinch effect" in a purely lateral cut record is what happens to the vertical component generated particularly with a cartridge like the Fairchild 225 that does not have vertical compliance?

dave

AHA!!! Dave, that is an excellent question.I think this is an interesting concept when you get to mono where conicals seem to "rule the roost". My problem with the "pinch effect" in a purely lateral cut record is what happens to the vertical component generated particularly with a cartridge like the Fairchild 225 that does not have vertical compliance?

dave

I've wondered the same. SOMETHING has to give. There is no doubt vertical excursion is happening. It is calculable, measurable electrically and observable. So, what is giving????

from the simple perspective I see two possible options. ... the stylus is either going to momentarily mistrack or excessively wear the groove at the pinch point. Neither can be a good thing.

dave

dave

Yes. Another possibility: perhaps they use less rigid cantilevers and/or have a bit of low compliance vertical excursion allowable???from the simple perspective I see two possible options. ... the stylus is either going to momentarily mistrack or excessively wear the groove at the pinch point. Neither can be a good thing.

dave

I have a Fairchild 225 here and indeed there is some vertical "give". I keep going back the the old saying that a "true mono" cartridge will destroy a stereo record due to the lack of (or reduced) vertical compliance. The pinch effect creating a vertical movement is just an extension of this. I seem to recall the Denon 102 was introduced in the early days of stereo as a true mono cart with vertical compliance for broadcast use so both mono and stereo records could be played with the same cartridge.

My guess is like your suggestion above that by the time anyone may have realized that this was an issue, mono was a thing of the past. I don't think anyone looked at a record in 1956 and ever dreamt someone would still be using it 65 years later.

My guess is like your suggestion above that by the time anyone may have realized that this was an issue, mono was a thing of the past. I don't think anyone looked at a record in 1956 and ever dreamt someone would still be using it 65 years later.

Dave Slagle,

regarding Mono you may see the many issued Mono & Stereo records today.

if you are in Mono you will experience a very different Audio pleasure

best

E.

audiocirc.com

audiocirc.com

audiocirc.com

audiocirc.com

regarding Mono you may see the many issued Mono & Stereo records today.

if you are in Mono you will experience a very different Audio pleasure

best

E.

New Plinth

made from Canadian wild oak massive wood my carpenter developed a completely new plinth for the Pierre Clement Mono system. The rubber based mounting suspension was carefully implemented. With the …

True Mono on Pierre Clement

I received my PC table from the repair shop, now updated with a better power cable and some silver signal cables. All bearings needed to be lubricated. It runs now like at the first day . It is co…

The Pierre Clement cart in your link has a cantilever design similar to the Fairchild 225. It has a flat horizontal cross section that gives immense strength in the lateral plane where needed and a fair amount of flex in the vertical plane. I see this flex as a bit of vertical compliance that may substantially help deal with the vertical content caused by the pinch effect. As an aside about using "cantilever flex" as part of the suspension this is exactly what the Neumann DST does. The flex of the cantilever which is rigidly anchored to the body is what determines the compliance of the cartridge.

dave

dave

Ortofon SPU Mono CG cartridges also have a flat cantilever design, presumably to give a touch of vertical complianceThe Pierre Clement cart in your link has a cantilever design similar to the Fairchild 225. It has a flat horizontal cross section that gives immense strength in the lateral plane where needed and a fair amount of flex in the vertical plane. I see this flex as a bit of vertical compliance that may substantially help deal with the vertical content caused by the pinch effect. As an aside about using "cantilever flex" as part of the suspension this is exactly what the Neumann DST does. The flex of the cantilever which is rigidly anchored to the body is what determines the compliance of the cartridge.

dave

I'd like to resurrect this thread. At AXPONA, I spent a lot of time at Wally tools listening to JR Boisclair. It seems to me that there are basically 4 parameters of cartridge set up that have to be set correctly:

1) Tracking force

2) VTA

3) Azimuth

4) Anti-skate.

Although there are any number of tools to help set these parameters correctly, the truth is that they can all be done by ear IF you have arm with adequate precision adjustments for each of these. (Adjustments in real time are ideal but not feasible in all tonearms).

However, the ONE thing we cannot control, which matters greatly, is the zenith alignment of the stylus on the cantilever.

According to JR, there are only 3 manufacturers of styli-cantlever-armature assemblies in the world and they make these assemblies for 99+% of all cartridge manufacturers. But here's what blew my mind. This parameter, according to JR, is not "quality controlled" at all. And without knowing this, it is impossible to set up any cartridge correctly if the zenith is not dead on or controlled with headshell mounting compensation (slight turn of the cartridge mounting to offset the mal-aligned zenith). So here's the 64K question: WHO DOES THIS?? Nobody I know (with the possible exception of Michael Fremer who really brought this to the attention of many of us in his column). Apparently it's not that hard. First you have to know your zenith angle (you can send your cartridge to JR for analysis), and then get one of his zenith alignment LPs (fairly inexpensive) so you can correct the cartridge mounting in any headshell (up to about 4 degrees).

So, the floor is open for discussion. If you don't correct for zenith, why not?

1) Tracking force

2) VTA

3) Azimuth

4) Anti-skate.

Although there are any number of tools to help set these parameters correctly, the truth is that they can all be done by ear IF you have arm with adequate precision adjustments for each of these. (Adjustments in real time are ideal but not feasible in all tonearms).

However, the ONE thing we cannot control, which matters greatly, is the zenith alignment of the stylus on the cantilever.

According to JR, there are only 3 manufacturers of styli-cantlever-armature assemblies in the world and they make these assemblies for 99+% of all cartridge manufacturers. But here's what blew my mind. This parameter, according to JR, is not "quality controlled" at all. And without knowing this, it is impossible to set up any cartridge correctly if the zenith is not dead on or controlled with headshell mounting compensation (slight turn of the cartridge mounting to offset the mal-aligned zenith). So here's the 64K question: WHO DOES THIS?? Nobody I know (with the possible exception of Michael Fremer who really brought this to the attention of many of us in his column). Apparently it's not that hard. First you have to know your zenith angle (you can send your cartridge to JR for analysis), and then get one of his zenith alignment LPs (fairly inexpensive) so you can correct the cartridge mounting in any headshell (up to about 4 degrees).

So, the floor is open for discussion. If you don't correct for zenith, why not?

The need to fine tune azimuth and zenith ( and quite frankly dial in vtf and vta ) are all for the same reasons - deviations from ideals in manufacturing. I don't see this as news.

What is up for debate is whether our ear is sufficient, or even better, versus measurement tools to find the adjustments.

Also we should expect high dollar carts to have grading applied to cantilever assemblies. As well as the rest of the parts. Despite this perfection will not he achieved

What is up for debate is whether our ear is sufficient, or even better, versus measurement tools to find the adjustments.

Also we should expect high dollar carts to have grading applied to cantilever assemblies. As well as the rest of the parts. Despite this perfection will not he achieved

I don't think the question is whether the ear is better than measurement tools. Rather, you can't do anything about an imprecise zenith alignment unless you know you have one. Do you know if you do or do not?The need to fine tune azimuth and zenith ( and quite frankly dial in vtf and vta ) are all for the same reasons - deviations from ideals in manufacturing. I don't see this as news.

What is up for debate is whether our ear is sufficient, or even better, versus measurement tools to find the adjustments.

Also we should expect high dollar carts to have grading applied to cantilever assemblies. As well as the rest of the parts. Despite this perfection will not he achieved

No issues regarding manufacturing QC. It's inexcusable when you are paying 10K + for a cartridge not to be assured the zenith is spot on.

Similar threads

- Replies

- 186

- Views

- 32K

- Replies

- 2

- Views

- 3K

- Replies

- 17

- Views

- 6K

- Replies

- 21

- Views

- 11K

- Replies

- 643

- Views

- 148K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |