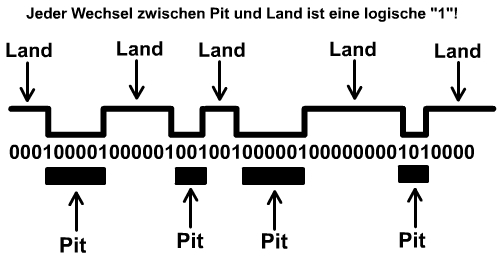

Well, for one thing a CD involves changing the original PCM file into "words" which can be represented by the pits and lands cut into the CD; that's why you can't just put a CD into your computer's disc drive and copy the files, it has to be "ripped". So right there is a possibility for problems to arise, and as you might suspect how well those pits and lands are cut and how well the reflective layer is then applied might affect eventual sound quality as well. Just some of the reasons many people say a CD ripped to hard drive and then played as a PCM file can sound better than the original CD. Needless to say manufacturing techniques have improved since the early days and quality control is better, but that doesn't mean "perfect".

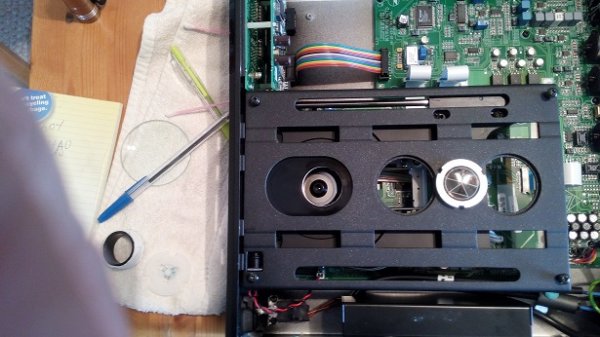

I think a lot of people don't know that the physical length of the land represents the length of a string of 0s making speed control a huge factor. Immunity from vibration too. We're not just talking about loss here we're talking corrupted output voltage data. That's why the information is printed on a CD five times in different locations IIRC. We hope one of the five is right and depend on error correction to find and use the correct ones. Not hard to imagine how tough that might have been when both pressing and transport manufacture were in their toddler years. I was one of those that thought bits are bits and that transports didn't matter until I moved from an ordinary CD player to a pro unit using a robust transport mechanism. My two current transports use the VRDS and Gyropoint respectively. The latter has a third laser used just as a sensor. Add that to the improvement in analog chips, analog sections and power supplies and we get a whole lot of improvement with rebook over the years. SSD appears to bypass most if not all these issues so I am eagerly waiting for computer audio to fully mature. It appears it will do so much faster. I'm just hoping that it happens in a manner that will not require the user to have a degree in computer engineering.