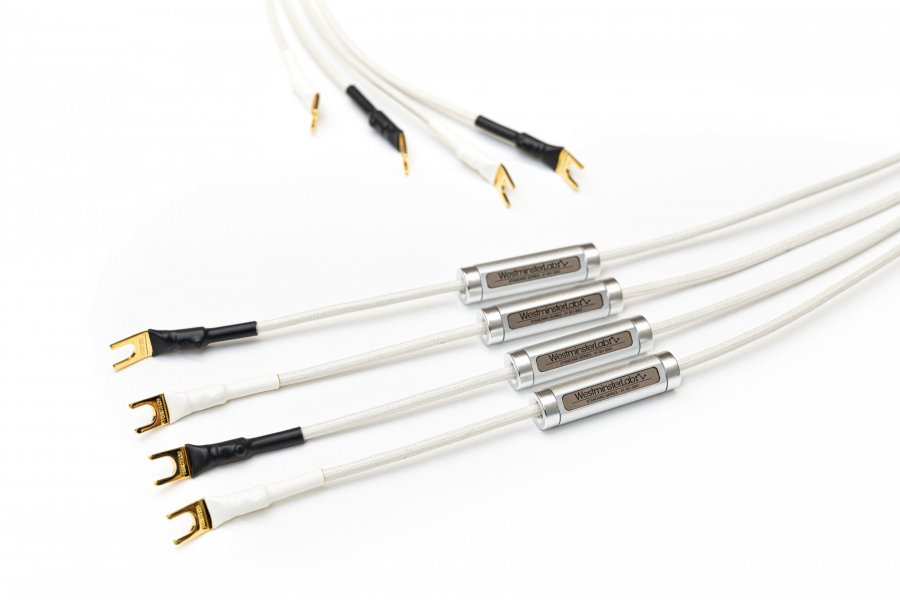

ENGINEERING THE CONNECTION

Technical Design White Paper by:

Angus Leung - Founder, and Chief Design Engineer for Westminster Lab

Mission:

To provide the audio system with the purest and cleanest signals possible in the analog, digital, and power delivery domains. We began our journey to create our cables by evaluating the more commonly used stranded conductors versus solid conductors. Our testing clearly showed that solid conductors were the best route for achieving our goals.

Conductor Design:

The advantage of the stranded conductors can be the cable's flexibility and a reduction of cost due to the more straightforward extrusion process. On the other hand, a problem with stranded conductors is that their structure generates a stray electric current within the strands. When a current flows through one conductor, it may transfer repeatedly into another rather than smoothly flowing from beginning to end. In turn, this creates turbulence within the cable's electron flow and causes an incidental sound and a reduction in smoothness, and an increase in audible distortion.

Conductor Material:

The conductor material is one of the most critical components in a cable. Our research included testing many different materials, such as high-purity copper, silver, gold, silver-gold alloy and other metals plated copper and silver. With these materials, at higher frequencies we found electrons flowing mostly on the perimeter rather than the conductor core. This changes throughout the cross-section of the conductor resulting in electrons moving through the conductor at various speeds generally resulting in an uneven frequency transition, artificial texture, and distortion of the image and soundstage. All WestminsterLab cables are using a unique conductor material that does not exhibit these characteristics.

As we also know, many producers use single-crystal copper and silver conductor where the crystal is continuous and unbroken with no grain boundaries and where electron flow jumps less from one crystal to another. But one downside is that whichever of these conductors is chosen their dominant sound signatures were comparatively slow and dense, while also exhibiting a distinct sound signature. We surmise this is where the industry terms “copper sound” and “silver sound” originated from.

Bespoke Conductors

We have developed our own conductor material using a special heat profile during the extrusion process. The result is a new type of conductor, which excels across a range of mechanical properties. We have named our proprietary conductor material

"Autria Alloy". As an additional part of the manufacturing process, the Autria conductor undergoes extensive heat and cryo treatment post extrusion. To achieve less distortion at higher frequencies, we then hand-polish each conductor to achieve a gloss mirror finish. Next, the conductor is polished and then protected with a special epoxy-based coating to eliminate oxidation. As a final step, the conductor is then inserted into a PTFE tube to further improve the conductors dielectric properties. The result is a conductive material free from a material sound signature with uniform material properties across the entire cross-section of the conductor.

Structures

As we know, simple twisting of a pair or pairs of wires can reduce crosstalk, RFI, and EMI.

According to Alexander Graham Bell:

“When a circuit is composed of two wires including a direct and a return wire they form a metallic circuit. This results in an inductive disturbance when placed in the vicinity of other circuits arising from the unequal inductive effect of the latter upon the two wires. Therefore, if the direct and return wires are affected equally, the current generated in one would neutralize and destroy what is created in the other. By placing the two wires in the same inductive relation to the disturbing currents, or, other conditions being the same, by placing them at an equal distance from the said circuits the problem is avoided.”

This, of course, does not always mean twisting the pair in the conventional method is always best because the method also exhibits disadvantages that include higher capacitance and inductance. Further, by twisting, a longer conductor is required to maintain the effective length which increases resistance. This led us to a deep examination of twisting vs not twisting cables.

The result is that an untwisted pair easily picks up noise around the environment, causing a noisier than desired background and increased distortion of the signal. Next, we tested the twisted pair, and it gives a cleaner and darker experience. The reason is that twisting a magnetic field generated by the current flowing in the signal conductor causes unwanted current flow in the paired conductor. After twisting, crosstalk between the wires can be canceled when an interfering signal is applied equally to both sides of a twisted pair. Therefore, the induced magnetic field or current will be minimized.

Vari-Twist

Having concluded that a twisted structure is the best way to go, the next question was how much or at what angle should the pair be twisted. The resulting angle must be enough to reduce interference, yet too big of an angle will generate more capacitance. As capacitance increases the speed of electrons is reduced, as is the overall bandwidth of the cable. Naturally, these two factors need to be balanced. In our testing, we found that a single angle cannot balance these two parameters because the method induces a particular resonance in a particular frequency range. While this method may work well for a single-frequency signal like digital, it may not be suitable for multi-frequency analog signals where your music lives. The ideal case is a cable twisted at a variable angle.

In our Vari-Twist design, the pair is twisted at varying angles throughout the length of the cable. The relationships between the signal pairs keep changing which minimizes the resonance at particular frequencies while interference and stray magnetic fields are also minimized. And this is one of the reasons all WesminsterLab cables in different lengths have their bespoke structure, all calibrated perfectly across the audio band.

Vari-Twist is unique to WestminsterLab and the only known cable to us that features this approach. While Vari-Twist among other design factors allowed us to reach our goals and therefore is well worth the effort.

Shielding

Common solutions are foil shielding and braided shielding. Some use tube shielding by a metal tube, achieving 100% shielding. Commonly used materials are tin, aluminum, copper, silver-plated copper, and nickel-plated copper. But in our tests, as long as a metal is used, rather than rejecting interferences it is absorbed and causes audible feedback to the system. Although these designs are often considered grounded, the resulting radio-wave changes to electricity and magnetic fields can affect the whole system. We describe this sonically as causing a negative effect on background darkness, soundstaging and dynamics.

This finding is the same as in our mono amplifier. Moreover, as long as there is a current flowing through the conductors, the current generates a magnetic field absorbed by the metal shielding that introduces feedback into the system resulting in a dull and dynamically restricted sound.

Finally, we offer an optional carbon fiber sleeve for shielding, which will not be affected by any magnetic field and rejects interferences without absorption in nature. When used in conjunction with Vari-Twist Technology, this brings the already state-of-the-art cable to a whole new level.

Conclusion

This is the process and materials our cables are engineered from. Naturally, we will continue exploring the limits of this technology. That said, for the foreseeable future whether you purchase our digital, analog, or power cables users can be assured of owning a cable that delivers the lowest distortion and highest level of musical satisfaction. I hope all the users enjoy our products and “experience music as it is”.

For more information on our complete cable line please go to our website

www. westminsterlab.com

To arrange an audition please contact our US Importer Gary Leeds

gary@hearthis.us

(949)467-9808