Dear Milan,

indeed I have dealt with some controllers and motors of different types.

I do believe on the importance of the speed stability, which should be independent from the groove modulation. Unfortunately I am one of those, who can feel the speed variation and this can drive me crazy, my daughter can feel it too. On the other hand, my wife and son are leading a happier life as they do not care.

Speed stability is offering me a superior involving sound experience and keeps me involved for hours. Speed accuracy on the other hand is of secondary importance as it is affecting the pitch.

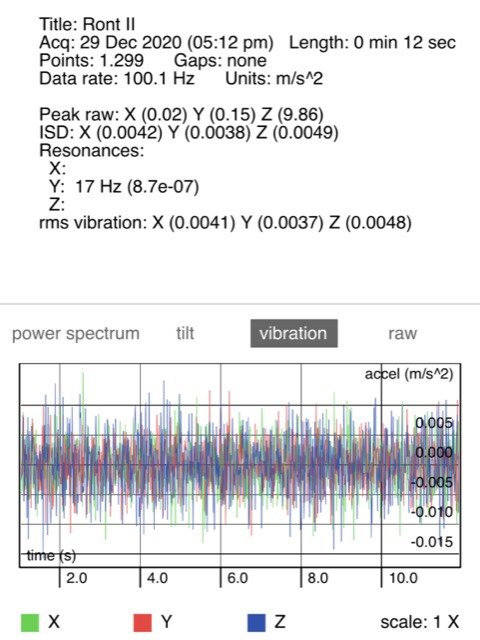

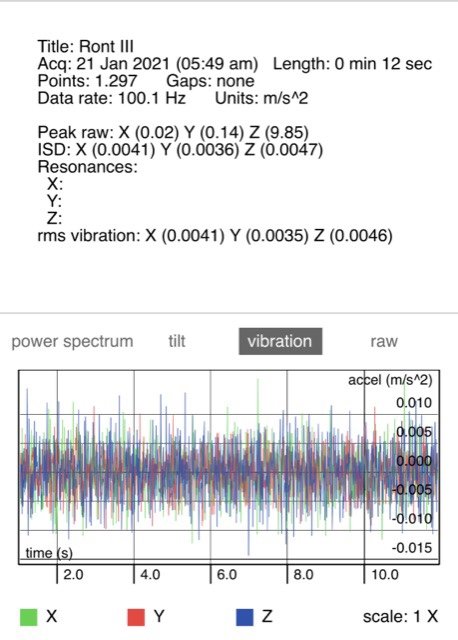

The speed stability and speed accuracy are directly associated with the interaction of the motor, the belt, the platter’s rotational mass ( rotational mass simplified ; how easy or difficult is to rotate the platter or to stop it once it is rotating and depends upon the platter’s mass and how this mass is distributed) and the bearing’s (bearing and thrust) quality.

None of the above elements (motor, belt, platter, bearing) can provide independently or alone, the speed stability and or speed accuracy. These are the fruits of well designed and engineered turntable and Brinkmann did it with Balance. The synergy of these elements is such that no speed feedback of any form is needed.

In regards with your question whether I hear a significant difference, my answer is definitely yes. But again to this question , probably you will get different answers from different listeners, who can (or can’t) feel the speed variation even in tiny amounts.

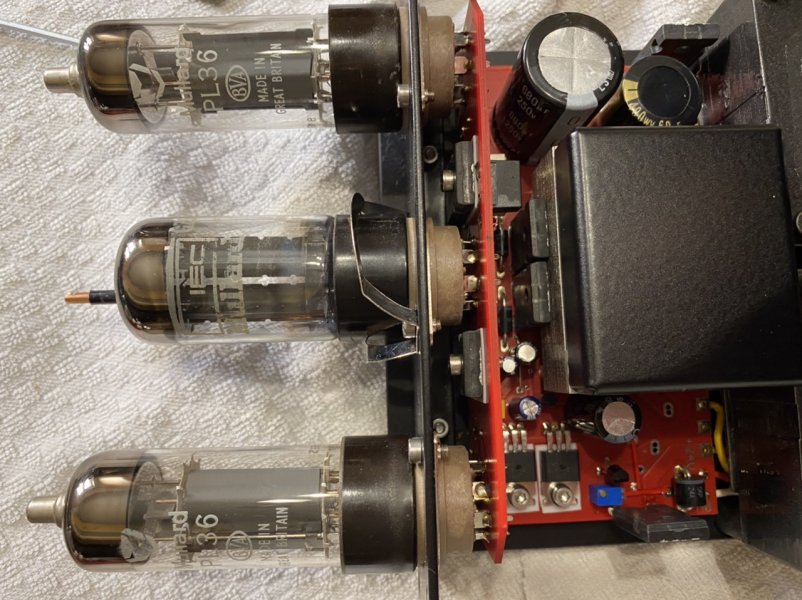

p.s. besides motors and controllers, I have extensively experimented with different belt shapes and materials as well as different bearings and thrust plates.

indeed I have dealt with some controllers and motors of different types.

I do believe on the importance of the speed stability, which should be independent from the groove modulation. Unfortunately I am one of those, who can feel the speed variation and this can drive me crazy, my daughter can feel it too. On the other hand, my wife and son are leading a happier life as they do not care.

Speed stability is offering me a superior involving sound experience and keeps me involved for hours. Speed accuracy on the other hand is of secondary importance as it is affecting the pitch.

The speed stability and speed accuracy are directly associated with the interaction of the motor, the belt, the platter’s rotational mass ( rotational mass simplified ; how easy or difficult is to rotate the platter or to stop it once it is rotating and depends upon the platter’s mass and how this mass is distributed) and the bearing’s (bearing and thrust) quality.

None of the above elements (motor, belt, platter, bearing) can provide independently or alone, the speed stability and or speed accuracy. These are the fruits of well designed and engineered turntable and Brinkmann did it with Balance. The synergy of these elements is such that no speed feedback of any form is needed.

In regards with your question whether I hear a significant difference, my answer is definitely yes. But again to this question , probably you will get different answers from different listeners, who can (or can’t) feel the speed variation even in tiny amounts.

p.s. besides motors and controllers, I have extensively experimented with different belt shapes and materials as well as different bearings and thrust plates.

Last edited: