Clean enough records and it is bound to happen -- filters get dirty.

The filter market can be a moving target as new different 'improved' models arrive and prior models get replaced, or the manufacturer simply drops a model or the manufacturer gets bought out or disappears. If you 'invest' in your own diy system, such as the one described in this thread, for myself I found it wise to acquire a cache of the filters that you use to assure availability when you need them. Just like tubes.

As part of my wash tank system I have a differential pressure gauge on my Pentek 150574 #10 filter cannister. That gauge finally went from green (clean) to yellow (change). I decided to change that filter as well as the rinse tank filter.

Wash tank filter: HP (Watts) FPP-0.2-975-DOE 2.5” x 9.75” DOE End Cap 0.2 micron absolute

Cannister: Pentek 150574, 3/4" #10 3G Blue Filter Housing with Bracket and Meter Mount

note: this cannister cannot be used without a gauge which is purchased separately. I use the Pentek

143549, Differential Pressure Gauge for 3G Meter Mount Housings.

Rinse tank filter: Flow Max FM-0.35-975 2-1/2” x 9-3/4” Pleated Filter, 0.35 micron nominal

Canister Pentek 158116 ¼” #10 Slim Line

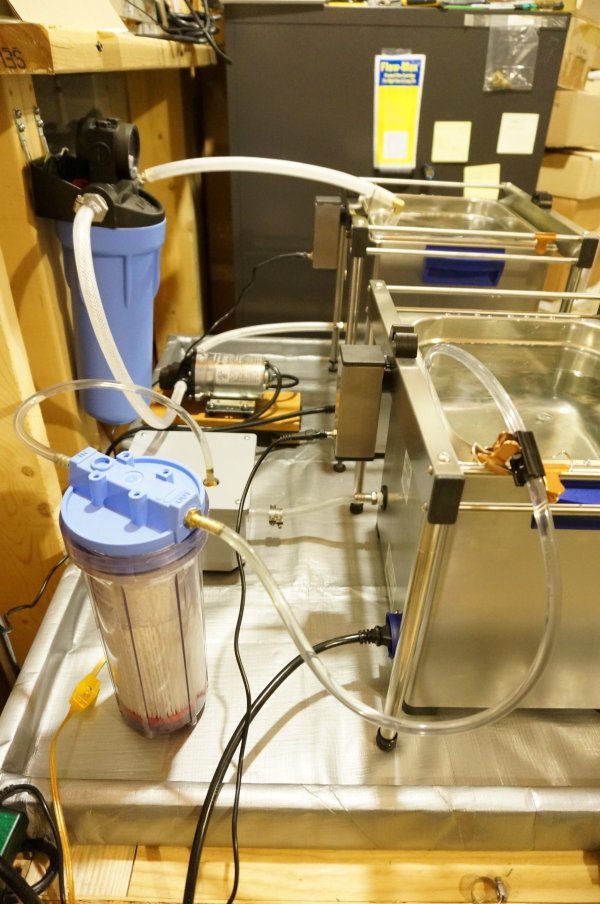

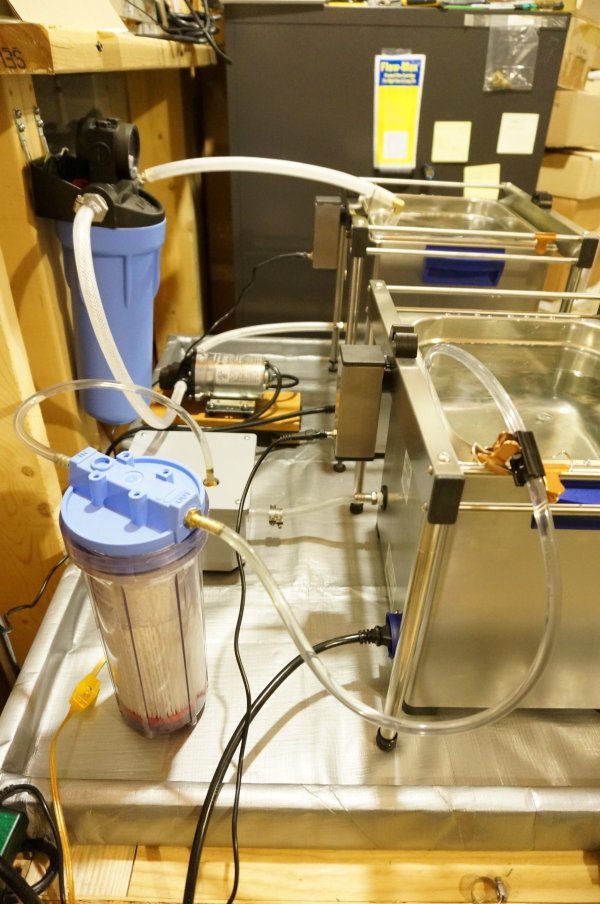

Both filters and their pumps.

Using this fairly large cannister I need 2 wrenches, one alone is too flimsy. The gauge only shows a reading when there is flow through the cannister.

Cannister now freed with a brand new filter.

When doing both filter changes I installed new O-rings.

- The wash tank filter cannister takes a Pentek 151120 Buna-N O-ring

- The rinse tank filter cannister takes a Pentek 151121 OR-38 Buna-N O-ring

- Both O-rings got a light coating of Dow Corning Molykote 111 O-Ring/Valve Lubricant/Sealent -- I was able to find a small 1/2oz. quantity

here.

Rinse tank cannister with unopened filter replacement.

These pictures give a comparison of used filter with new filter. Hopefully the pictures here show at least the discoloration of the old filters. The differences are more apparent in real life.

Wash tank new (R) and old (L).

Rinse tank new (R) and old (L).

Full system specs and parts list

here.