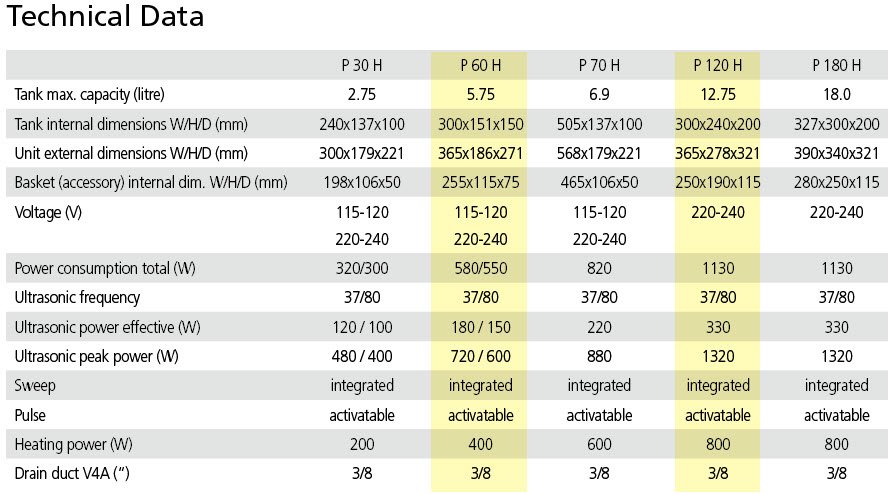

A UT tank specs do not always indicate the real power especially for the inexpensive Chinese units. You can measure the power draw using an inexpensive watt meter and measure how quickly the bath heats from UT alone (heaters de-energized). Ultimately most UT power into the tank (absent losses if the tank is thin and vibrates) converts to heat which heats the bath. The Elmasonic P-series and say the 6L P60H https://www.elma-ultrasonic.com/fil...lgeraete/Elmasonic_P/PP_Elmasonic_P60H_EN.pdf heats the bath quite quickly and you will see where the Elmasonic has multiple UT power rating - effective and peak. People who serially clean records with the Elmasonic may install a pump/filter with radiator to keep the bath temperature under control. An example is detailed in Chapter XIV of this free book - https://thevinylpress.com/precision-aqueous-cleaning-of-vinyl-records-3rd-edition/Thanks! What specs indicate a high powered machine?

Also- Are you saying that 0.27 RPM for 11 minutes in a high powered machine risks damage but 0.5 RPM for 11 minutes in a high powered machine does not risk damage? I am trying to understand what is more important when it comes to damage. Total time or submerged time per revolution.

For risk of damage, it's four variables, UT frequency, power, temperature and continuous exposure time (not total accumulated time). This post (and the linked book) gives the basic thumb-rules for UT https://www.whatsbestforum.com/threads/ultrasonic-cavitation-cleaning-explained.36690/post-870704. Lower kHz produces a larger cavitation bubble that when it collapses produces a cavitation intensity greater than higher kHz machines.

EDIT: One other variable is the record itself with some (for unknown reasons) more susceptible than others.

Last edited: