PART 1

Just been back from vacations and i feel my batteries fully charged!

So i am going to write (in episodes) the story about my resident DIY turntable...

It all started back on 1986 when i finished high school and had successfully

entered the University community.My father bought me as a gift, a Mitsubishi

set of components (amp/preamp/cassette player/tuner and THE Turntable:the LT-5V) plus

floor standing danish Jamo speakers.

Poor man had to give a down payment and i had to help paying up the monthly payments

as the total was 4 times his monthly salary (a schoolteacher).About 1/3 of that was the

cost of the turntable and rightfully so!

IT WAS (AND STILL IS!) EYE CANDY!!!

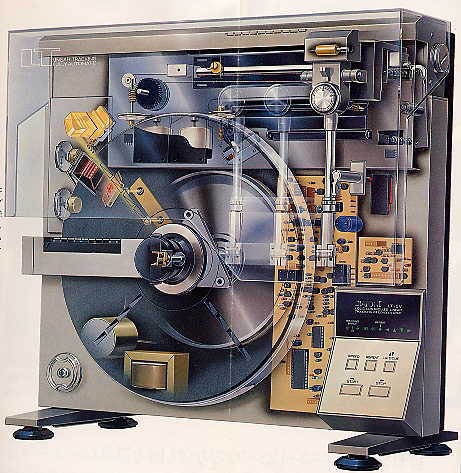

It was vertical,the record had to be pushed onto the platter and stabilized with a clamp,

was completely automatic (record size sensing/speed set/cue in/end lift ) and was using

a complicated parallel tracking arm that in contrary to the norm had a (limited) pivot movement!

It was belt driven, with a motor that would rotate a sub-platter at the back, connected with

a polished steel rod with the platter on the front.Cartridge was an MM AudioTechnica.

There was not a single person that would come into our house and not gasp in amazement

looking at it!See below the "transparent" image that gives an idea of the mechanisms involved!

Through this turntable i listened all the records of my university years...It worked without

a single problem for years and years.

At times other turntables came and went (best was a DENON DP72L) but this was with me

always even after i made my own family and moved to my house.

Through the years i came to understand the way it worked,it's strong points and it's weak ones!

The parallel tracking mech was very well executed but a lot of things could be done to support

it's function.So at first, i took out the power supply and placed it in a separate case,took out the motor,placed it in a separate iron ''tower'' and used a longer belt to rotate the sub-platter.I have designed a different clamp that utilized a stiffer spring to gain better contact between records/platter.

Then i tossed away the original (rather flexible) feet and used in their place a solid 3cm MDF board

with Sony ES feet,used extra MDF boards to strengthen the chassis, changed the tonearm wires

to silver ones and bought a nice VDHul "The Frog" cartridge.Last of all i painted it black from

the original silver.With this transformation the sound moved up several notches and i was in content

for another seven years...

Until an audio friend saw it and said :"I WANT THIS ONE!" and had the money to back up his statement!

I knew that working samples of this were sold at ebay for around 150 euro,and so i promised my

friend that he could have mine the moment i could make a "new" one the way i have dreamed it!

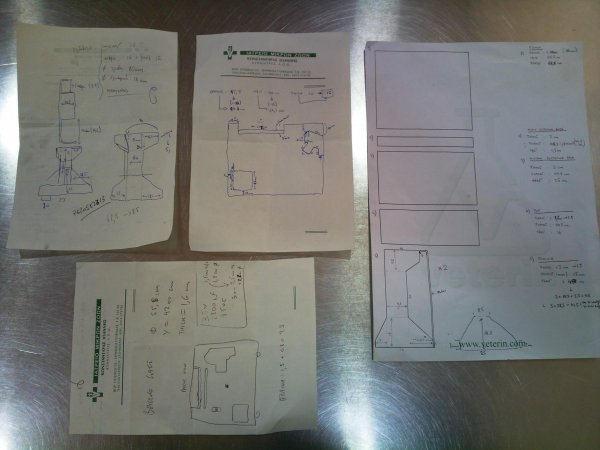

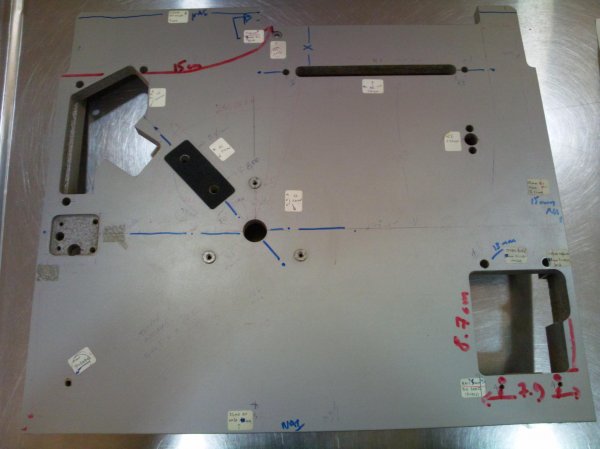

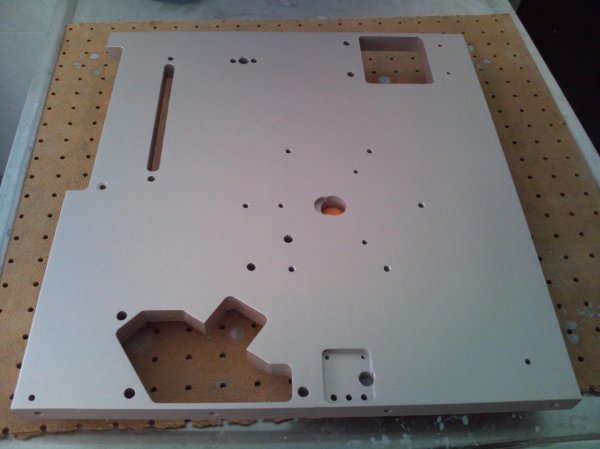

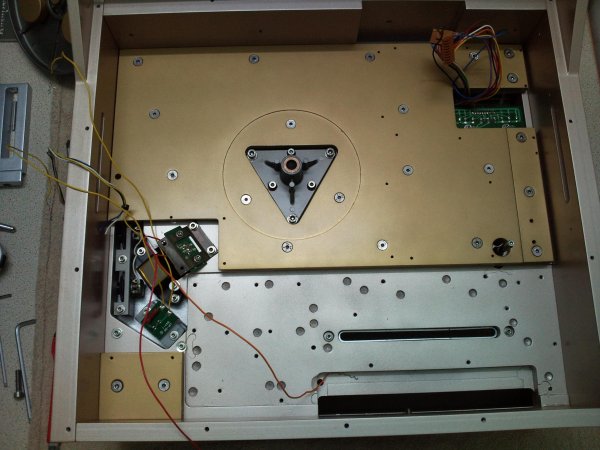

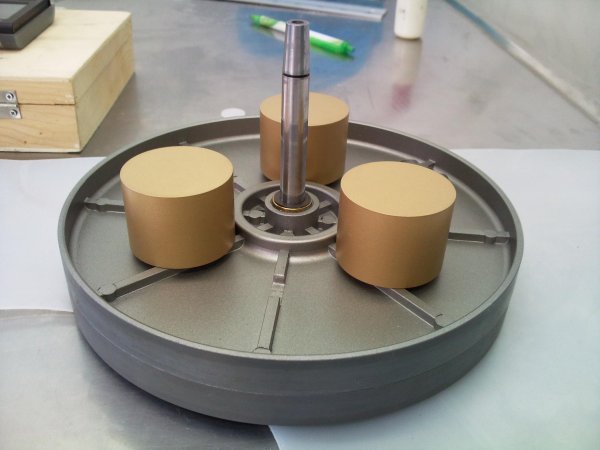

I wanted rigid chassis construction,twin motors,heavier platter/sub-platter assembly,superb power regulation,better tracking and looks to die for.

So i bought two working samples to use as donors for all the parts i needed and started to design

the shape of things to come...

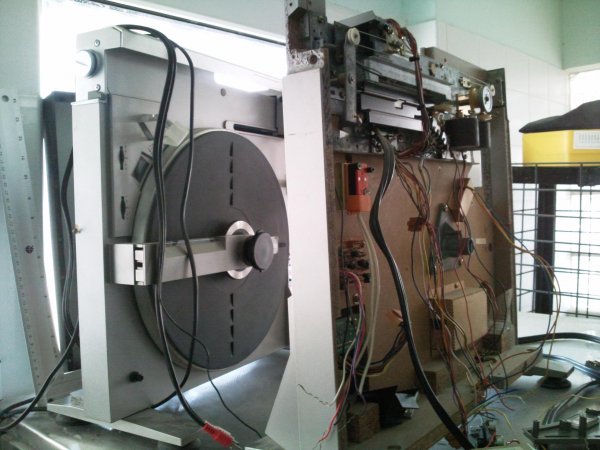

And on the second picture is the LT-5V in my system on the described (modded) shape,

Just been back from vacations and i feel my batteries fully charged!

So i am going to write (in episodes) the story about my resident DIY turntable...

It all started back on 1986 when i finished high school and had successfully

entered the University community.My father bought me as a gift, a Mitsubishi

set of components (amp/preamp/cassette player/tuner and THE Turntable:the LT-5V) plus

floor standing danish Jamo speakers.

Poor man had to give a down payment and i had to help paying up the monthly payments

as the total was 4 times his monthly salary (a schoolteacher).About 1/3 of that was the

cost of the turntable and rightfully so!

IT WAS (AND STILL IS!) EYE CANDY!!!

It was vertical,the record had to be pushed onto the platter and stabilized with a clamp,

was completely automatic (record size sensing/speed set/cue in/end lift ) and was using

a complicated parallel tracking arm that in contrary to the norm had a (limited) pivot movement!

It was belt driven, with a motor that would rotate a sub-platter at the back, connected with

a polished steel rod with the platter on the front.Cartridge was an MM AudioTechnica.

There was not a single person that would come into our house and not gasp in amazement

looking at it!See below the "transparent" image that gives an idea of the mechanisms involved!

Through this turntable i listened all the records of my university years...It worked without

a single problem for years and years.

At times other turntables came and went (best was a DENON DP72L) but this was with me

always even after i made my own family and moved to my house.

Through the years i came to understand the way it worked,it's strong points and it's weak ones!

The parallel tracking mech was very well executed but a lot of things could be done to support

it's function.So at first, i took out the power supply and placed it in a separate case,took out the motor,placed it in a separate iron ''tower'' and used a longer belt to rotate the sub-platter.I have designed a different clamp that utilized a stiffer spring to gain better contact between records/platter.

Then i tossed away the original (rather flexible) feet and used in their place a solid 3cm MDF board

with Sony ES feet,used extra MDF boards to strengthen the chassis, changed the tonearm wires

to silver ones and bought a nice VDHul "The Frog" cartridge.Last of all i painted it black from

the original silver.With this transformation the sound moved up several notches and i was in content

for another seven years...

Until an audio friend saw it and said :"I WANT THIS ONE!" and had the money to back up his statement!

I knew that working samples of this were sold at ebay for around 150 euro,and so i promised my

friend that he could have mine the moment i could make a "new" one the way i have dreamed it!

I wanted rigid chassis construction,twin motors,heavier platter/sub-platter assembly,superb power regulation,better tracking and looks to die for.

So i bought two working samples to use as donors for all the parts i needed and started to design

the shape of things to come...

And on the second picture is the LT-5V in my system on the described (modded) shape,

Attachments

Last edited: