Hi Tima and everyone,

I have posted in this thread before, but seeing Tima’s new pics has led me to post this update. I have made changes, many of which are more in line with other posters. There is also new information here that may be helpful.

If you are interested, my previous posts begin with post

#20

I have not changed my final Loricraft cleaning/rinsing strategy which is key to the most wonderful sound available on vinyl (IMHO). For those who might disagree, try it and you will likely change your mind.

A brief list of changes:

I switched from Everclear (grain alcohol) to MG Chemicals 824-1L IPA. You can buy ten liters here for $12.68 @

https://www.digikey.com/en/products/detail/mg-chemicals/824-1L/9181284

I changed from two filters to one and reduced the number of hoses and fittings.

I changed my standard cleaning cycle to 50 minutes at either 80 Hz, or I use the Elmasonic 37/80 Hz cycle.

I have lowered the temperature range for cleaning to 30-40 degrees C.

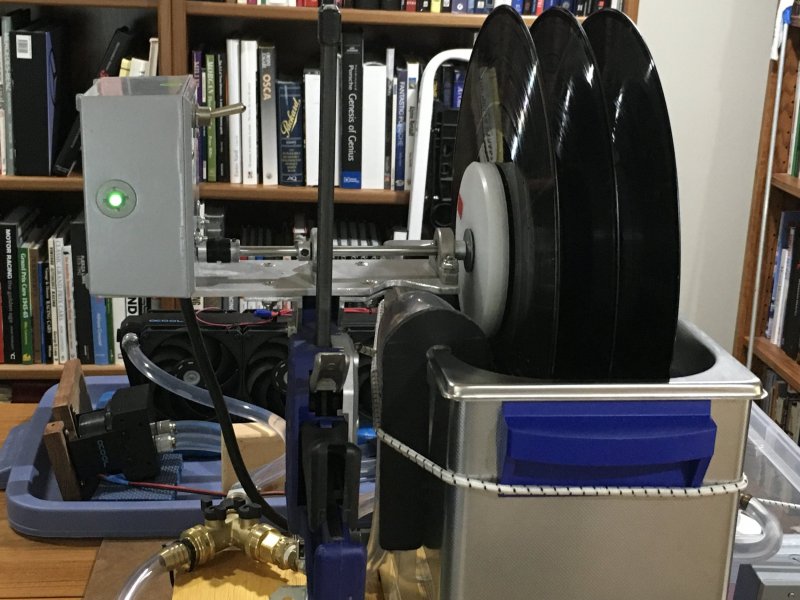

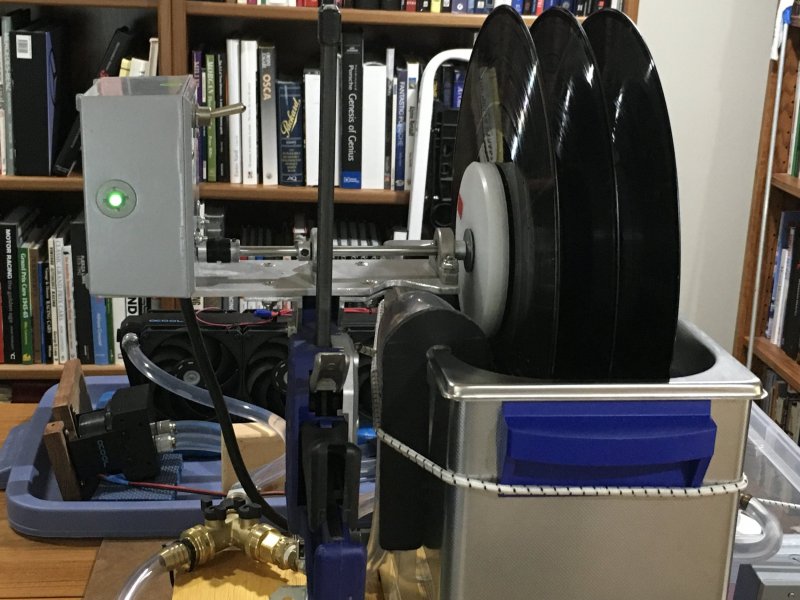

I changed the way I removed the water/IPA after cleaning to a record spinner that I made.

It is essentially a 4000 rpm drill and an oil drip tray.

I discovered quickly that records need to spin at 4000 rpm to dry them quickly (< 30 seconds). This can create imbalance problems with some records, so you should proceed with caution if you follow this approach. I can add further details if anyone is interested.

After drying the records, I clean/rinse them again on my Loricraft. This is about 10 minutes per disc.

That’s about it, but I left out the logic behind all of this, so here is where you need to fasten your seat belts:

I have been washing records with various methods since about 1980. One fact I have always recognized is that alcohol, while it is an excellent cleaner, or probably because it’s an excellent cleaner, also leaves a dryer, less lubricated surface: it changes the coefficient of friction of the vinyl. Every cleaning fluid I have ever used leaves a slightly different friction surface for the stylus as revealed by a different sound.

To me, an alcohol cleaner results in a more brittle, thinner, more edgy sound. It can be a subtile or dramatic change, but it is always, IMO, worse and less like the original sound.

Somewhere along my path, I discovered L’Art du Son, and began using it in my VPI 17F cleaner. My frustration with record cleaning also increased, because the VPI only worked reasonably well for the first side of the first record. After that, the felt strips on the vacuum tube were dirty and records sounded worse.

Armed with a dozen or so tubes, a toothbrush, and a big pan of distilled water to clean the tubes in, I limped along for a few years. Until I discovered Loricraft! Now my records were not only cleaner, but were consistently clean!

The Ultrasonic then entered the picture, and the real change with ultrasonic is that the cleaning process is far more thorough and more consistent than other methods.

I wanted to continue using L’Art to avoid the effects of alcohol, so I did the L’Art after the ultrasonic.

Meanwhile, as my music system got better, I discovered that while L’Art sounded good, the sound was veiled in comparison with a new disc.

I started thinning the L’Art further than the recommendation of one gallon of distilled water per bottle of L’Art. After a lengthy series of experiments, I determined that FIVE gallons of distilled water per bottle of L’Art were required to eliminate any audible veiling of the sound. Fortunately, this still left a record surface that had none of the negative effects of alcohol, and sounded more natural, more analog if you will, than a new (washed or unwashed) record. Five gallons is a reduction of 172:1. I determined that there was a subtile but consistent sound change between this and 168:1. Again, doubters can do their own experiments. (I have my Nomex britches on now, so fire away)

The mechanics for doing this is to mix up the original one gallon of L’Art, and then, as required, thin it with one part of the mix and four parts of additional distilled water.

There are additional advantages of using this system: I’m not concerned with absolute cleanliness of the ultrasonic fluid. I rely on wiping or vacuuming dust off records before I start, and the 0.3 micron filter does the rest. I only change the fluid every six months or so.

The Loricraft L’Art provides three final benefits: cleaning, rinsing and surface treatment.

I can do five times as many records with one $50 bottle of L’Art.

I do not use any surfactant in the ultrasonic. I can hear the effects of surfactants in the mix and I don’t like it. In addition the percentage of surfactant in the fluid continues to increase and the effects worsen.

I have discovered, however, that maintaining a specific percentage of IPA in the ultrasonic bath is more difficult than it first appeared.

I purchased a hydrometer for measuring small percentages of IPA in water:

https://www.belart.com/h-b-b61809-4000-durac-0-50-isopropyl-alcohol-hydrometer.html

or:

https://www.amazon.com/Percent-Isop...0%+isopropyl+hydrometer&qid=1612722148&sr=8-2

I had a couple of other hydrometers (none were accurate enough) before I found this one.

I was trying to maintain a 5% IPA level in the water. The initial mix was no issue, and the hydrometer measured 5%.

I mixed up a reserve supply of 5% mix to add to the fluid in the ultrasonic as it evaporated. (I keep a piece of Saran Wrap over the tank when it is not in use.) But the level of IPA dropped to 3 or 4% after a few days.

I changed the premix to 40% and the percentage of IPA in the tank went UP. So now I am at about 25% and the 5% mix is holding its own. YMMV on this

There is more that could be said here, but I think I have hit the high points. If you are still with me after all this, thanks for sticking it out. I hope to meet you at the next L’Art Convention.