@tima & @Stacore,

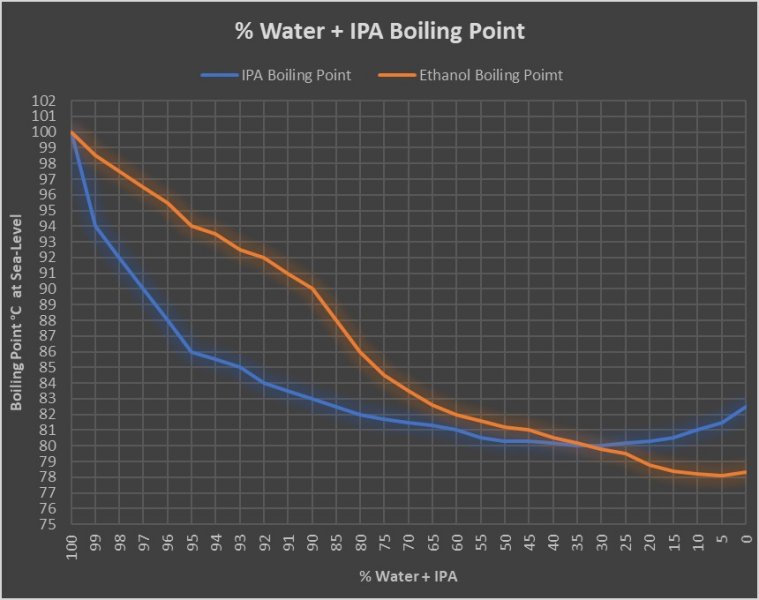

I went back and reviewed the Flashpoint, Surface Tension and Boiling Point of Water+Ethanol. There are some minor differences in Flashpoint and Surface Tension, but not of much consequence (I will add the data if there is a 3rd Ed of the book).. BUT, there is major difference in the boiling point at the lower concentrations, enough that use of ethanol to improve drying is not valid. Note that the attached graph is not to uniform scale - the X-axis is expanded between 0-10% ethanol to better see the data. EDIT - graph updated with better ethanol data.

I went back and reviewed the Flashpoint, Surface Tension and Boiling Point of Water+Ethanol. There are some minor differences in Flashpoint and Surface Tension, but not of much consequence (I will add the data if there is a 3rd Ed of the book).. BUT, there is major difference in the boiling point at the lower concentrations, enough that use of ethanol to improve drying is not valid. Note that the attached graph is not to uniform scale - the X-axis is expanded between 0-10% ethanol to better see the data. EDIT - graph updated with better ethanol data.

Attachments

Last edited: