I have heard a lot about what different chemicals can do to the delicate lp.all I do is brush a lp before playing.all my lps are noise free And never being cleaned by chemicals.there’s people who believe lps need to be washed and cleaned and than there’s those who don’t believe in it at all.Would be easy enough for you to test that belief, but why do you feel they are better left alone?

tima's DIY RCM

- Thread starter tima

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just for clarification, the LP is not delicate. Studies by the Library of Congress have determined that the vinyl-LP is the most survivable physical audio media there is; details here: pub164.pdf (clir.org). The vinyl record is remarkably robust. There are some solvents such as ketones (used to weld PVC) that will damage/dissolve the vinyl record. But by and large the vinyl LP is pretty immune to most aqueous based cleaning products that are not dangerous and used with any reasonable care.I have heard a lot about what different chemicals can do to the delicate lp

The frequent discussion that the plasticizer will be removed is nonsense. If the vinyl LP contained any significant amount of plasticizer, it would never last as long as it does, it can and it will. Plasticizers over time migrate from PVC which is a major reason why flexible PVC that contains >10% plasticizer degrade.

The two environmental factors that can degrade the vinyl record are sunlight (intense UV) and heat. Once the record is over about 55C (131F) it begins to release hydrogen chloride gas. The record has stabilizers to scavenge the gas during the heated pressing process and there will be some stabilizer reserve left. But once the stabilizer is exhausted the surface will harden, embrittle and micro-cracks form. At this point, the record does not stand a chance against that stylus. I suspect that records that contain repressed material are more susceptible to heat degradation because there may not have as much stabilizer reserve.

The biggest problem with cleaners is overuse and not effectively rinsing so you leave residue behind. Take a small sample (1/4/ to 1/2 teaspoon) of any cleaner in its ready-to-use concentration, and spread on a clean glass, porcelain or stainless-steel surface and let it evaporate. What is left behind (the non-volatile residue) is what is left on the record if not rinse.

Note that I am not trying to convince you to do different than what you are doing, only clarifying some items for the benefit of others who may be reading.

Neil

I was measuring various cleaning products with a TDS meter the other day (Liquinox mix came out around 450ppm) and it got me thinking it would be incredibly useful if there were a way to objectively measure residue on a surface, ie something like a TDS meter which could "read" a surface and display how much residue was there - maybe conductance or something. Anyway, when I measure the bath water after cleaning it's ~1ppm, so I am sufficiently certain that the liquinox and subsequent surfactant are adequately removed/diluted by my method not to be an issue.What is left behind (the non-volatile residue) is what is left on the record if not rinse.

Just for clarification, the LP is not delicate. Studies by the Library of Congress have determined that the vinyl-LP is the most survivable physical audio media there is; details here: pub164.pdf (clir.org). The vinyl record is remarkably robust. There are some solvents such as ketones (used to weld PVC) that will damage/dissolve the vinyl record. But by and large the vinyl LP is pretty immune to most aqueous based cleaning products that are not dangerous and used with any reasonable care.

The frequent discussion that the plasticizer will be removed is nonsense. If the vinyl LP contained any significant amount of plasticizer, it would never last as long as it does, it can and it will. Plasticizers over time migrate from PVC which is a major reason why flexible PVC that contains >10% plasticizer degrade.

The two environmental factors that can degrade the vinyl record are sunlight (intense UV) and heat. Once the record is over about 55C (131F) it begins to release hydrogen chloride gas. The record has stabilizers to scavenge the gas during the heated pressing process and there will be some stabilizer reserve left. But once the stabilizer is exhausted the surface will harden, embrittle and micro-cracks form. At this point, the record does not stand a chance against that stylus. I suspect that records that contain repressed material are more susceptible to heat degradation because there may not have as much stabilizer reserve.

The biggest problem with cleaners is overuse and not effectively rinsing so you leave residue behind. Take a small sample (1/4/ to 1/2 teaspoon) of any cleaner in its ready-to-use concentration, and spread on a clean glass, porcelain or stainless-steel surface and let it evaporate. What is left behind (the non-volatile residue) is what is left on the record if not rinse.

Note that I am not trying to convince you to do different than what you are doing, only clarifying some items for the benefit of others who may be reading.

Neil

A truly excellent post Neil.

The follow-up would be why no or little cleaning or mere brushing is detrimental to a record's future. Here is my paean to that:

I believe more records have been made than will be made in the future - let's hope I wrong. Even more strongly I believe more AAA all analog records have been made than we're likely to ever see made again given that the vast majority of modern production derives from digital recording. There are a few holding the all analog tradition alive but alas they are today the exception.

I believe there is general consensus that original editions - the likes of Mercury's, Deccas, RCAs, Lyritas, Blue Notes and many others - are highly valued for their better sonics over reissues. Those need to be preserved. That's not a knock on quality reissues, I been allowed to experience a lot of music I would not otherwise have if it were not for them. They too need to be preserved. I was so happy to see @Mike Lavigne take this up - he has a vast collection, maybe not all are 10's but many are of music we may never hear recorded again.

We vinylists should remind ourselves of this. We love building collections but we need to keep in mind that we, in the end, are curators for our time, hopefully passing those collections on to others who will love them as much as we love their music today. I believe we have an obligation to this curation and preservation and that keeping one's records clean is an integral part of owning vinyl. It is vital to the viability of our hobby.

When someone asks advice about getting into vinyl don't forget to tell them about keeping their records clean. Most fortunately technologies have been maturing over the past ten years to further this goal. We have made progress and will continue to further it - the knowledge is there, thanks to experts like Neil - we simply need to act upon it. Living La Vida Vinyl!

I was measuring various cleaning products with a TDS meter the other day (Liquinox mix came out around 450ppm) and it got me thinking it would be incredibly useful if there were a way to objectively measure residue on a surface, ie something like a TDS meter which could "read" a surface and display how much residue was there - maybe conductance or something. Anyway, when I measure the bath water after cleaning it's ~1ppm, so I am sufficiently certain that the liquinox and subsequent surfactant are adequately removed/diluted by my method not to be an issue.

This is why I refuse to use stuff like Hepastat 256. Yes filtering and rinsing may remove some or all of it, but I'm not inclined to add a non-cleaning agent that I want removed.

cf.

Which ultrasonic now that KLAudio is out?

Nice to know you have all the answers. My main point was addressing your post #21, stating that IMHO there a lot we do not know about the short and long term effects of ultrasonic cleaning . Anyway it would be nice to know exactly what proper stuff that chemists have approved you use for...

I'm using a DeGritter with only distilled water.

I don't use the cleaning solution supplied by DeGritter or any other. The DeGritter is loud when in use so I keep it is a spare room in the back of the house. However, it gets the dirt off - even on new records.

I change filters app every 50 records (very simple). I change water app every 25 records.

I don't use the cleaning solution supplied by DeGritter or any other. The DeGritter is loud when in use so I keep it is a spare room in the back of the house. However, it gets the dirt off - even on new records.

I change filters app every 50 records (very simple). I change water app every 25 records.

First, the TDS measurement is actually an approximation; and it only measure the electrical conductivity/resistivity of the water. Chapter VII, Table IV, Note 1: Total dissolved solids (TDS) listed is a conversion from resistivity and for purified water and better assumes only chloride and sodium salts, and uses a conversion factor of 0.5. The formula for TDS = (K) x (1/Resistivity). There are different K factors.I was measuring various cleaning products with a TDS meter the other day (Liquinox mix came out around 450ppm) and it got me thinking it would be incredibly useful if there were a way to objectively measure residue on a surface, ie something like a TDS meter which could "read" a surface and display how much residue was there - maybe conductance or something. Anyway, when I measure the bath water after cleaning it's ~1ppm, so I am sufficiently certain that the liquinox and subsequent surfactant are adequately removed/diluted by my method not to be an issue.

Second, the Liquinox reads high because of the anionic surfactants; these are ingredients that are doing the heavy cleaning. The nonionic surfactant in Liquinox is not detected by the TDS meter. However, your conclusion that it is rinsed by the TDS measurement of the bath water is valid. The nonionic surfactant is a homogenous part of the cleaning solution and it's about 30%; 70% is anionic, so a measurement of ~1ppm is valid that the cleaner (Liquinox) has been rinsed.

Your extensional question is there a device that can read/measure surface contamination - the answer is nothing that is as simple as a TDS meter. Noting that nonvolatile residue (NVR) can include both ionic and nonionic residue, surface electrical condition is not valid. There is a whole science for verification of surface cleanliness. There are surface quality meters (SQM) that can be used to measure the surface cleanliness of certain UV light reflective flat surfaces such as stainless steel, but these would not be usable for the record.

Because the record groove is so irregular, for similar type surfaces, today industry using an aqueous cleaning procedure will use a high purity solvent such as CFC-113 (very little left, manufacture stopped 1996) to wash a cleaned surface, collect the solvent, filter to measure particles and then evaporate to determine NVR. This is time-consuming and costly, but is appropriate for critical applications. The book Chapter XI Table VI provides examples of industry surface cleanliness limits. Note that in-general industry generally does not consider NVR from hard-water (i.e., calcium/magnesium salts) a contribution to NVR because rinse water is accurately monitored with conductivity/resistivity meters. An exception is semi-conductor chip manufacture. This is a very controlled environment - they are not machining metal parts, and they use predominantly ultra-pure water and mega-sonics for cleaning. In this case, the water is a solvent so it can be directly/continuously measured for conductivity/resistivity, particle counts and total organic carbon; but they will still do individual chip surface cleanliness inspection with microscopes.

However, there now appears to be an emerging technology that can optically determine surface cleanliness. Olympus has digital microscopes such DSX1000 High-Resolution Model | Digital Microscopes | Olympus (olympus-ims.com) that can magnify up to 8220X. They also have the Cleanliness Inspection System | CIX100 | Olympus (olympus-ims.com) which is intended for cleanliness inspection of particles as small as 2.5um. However, there are cleanliness levels - MIL-STD-1246 Level 10 and less that are measuring particle of 1um; and the semiconductor industry is well below that. I have no idea of the cost of something like an Olympus CIX100 (let alone the DSX1000), but I am pretty sure it's at least 5-figures and you still need a very stable platform for image stability - think massive slabs of granite to begin with.

So, not to get any deeper into this. The short answer - no simple, inexpensive method to directly measure surface cleanliness.

Neil

Tim,This is why I refuse to use stuff like Hepastat 256. Yes filtering and rinsing may remove some or all of it, but I'm not inclined to add a non-cleaning agent that I want removed.

In my response to @rDin hopefully you caught that the anionic surfactant in the Liquinox which is doing the heavy cleaning is the source of the TDS. As a pre-cleaner, it is very effective, and as I wrote above, you can verify removal by the final rinse water TDS.

However, I always recommend a nonionic cleaner for final cleaning, be it DIW or DIW with some nonionic surfactant. Using TDS, it makes it easy to verify any ionic pre-cleaner or residue was removed.

HEPASTA 256, although a favorite of some forums, is not really a good cleaner for records. Its use was recommended only because of the high concentration of cationic surfactants and I address the benefits of cationic surfactants in the book Chapter VIII. However, HEPASTAT 256 concentrate also has a bunch of other stuff and I break it down in Chapter VIII.13.2: ~20% cationic surfactants + 8% nonionic surfactant + 10% sodium metasilicate & EDTA. The sodium metasilicate is a high-alkaline-builder, no foaming and used in most dishwashers. If it dries in-place, it dries to essentially glass. From the perspective of cleaning a record, sodium metasilicate is the last product I would ever recommend to clean a record with a DIY formula. PS/I have to two US Patents, and they are both in silicate cleaning chemistry so I have some knowledge of silicates.

Neil

As I wrote in the book in the beginning of Chapter VI:The follow-up would be why no or little cleaning or mere brushing is detrimental to a record's future.

VI.1 In the technical paper THE WEAR AND CARE OF RECORDS AND STYLI, by Harold D. Weiler, 1954 (26) states “Many methods have been devised and improvised to combat the problem of dust on records and to reduce its effect on wear and reproduction. However, none of these methods were ever completely effective, and they all passed into oblivion with one exception, the cleaning pad. Unfortunately, this device is in general use in 1954, despite the fact that it does not clean records! A record pad can actually damage records by scratching them and grinding microscopic particles of dust and grit into the grooves. In addition to causing excessive wear of records and styli, these dust particles also increase the noise level of the record. Since the particles of dust and grit are often as large as the recorded impressions in the record groove which create the sound, they will affect the stylus movement, causing random impulses which are translated as noise. This increase in noise level due to dust and grit is the biggest contributing factor to the hissing sound commonly and mistakenly referred to as "needle scratch”.

VI.2 In the paper Record Contamination: Causes and Cure by Percy Wilson, 1965, (52) it echoes what Harold D. Weiler wrote and discusses how dry cleaning can give back more than it removes. The dry-cleaning material will ultimately become saturated with particle/soil and then instead of removing, redeposits to the record. The paper also states that “…repeatedly-used damp pad or like device can become a positive menace.”

My position is that once cleanliness is established by a precision cleaning process, the only thing that belongs in the groove is the stylus. The very fine powder that will develop in the groove from minor stylus and record wear is inconsequential provided it stays dry. It will just blow around as the stylus tracing the groove. Think very dry snow powder, it just blows around; not so much when it gets wet. I have been playing with a new method/material that uses no brush or fabric to remove most lint/particles from the surface and has anti-static properties, total cost <$40 and should last many lifetimes. It's not perfect, but so far it proving the best I have found and easy to live with; details to follow.

Neil

Tim,A truly excellent post Neil.

The follow-up would be why no or little cleaning or mere brushing is detrimental to a record's future. Here is my paean to that:

I believe more records have been made than will be made in the future - let's hope I wrong. Even more strongly I believe more AAA all analog records have been made than we're likely to ever see made again given that the vast majority of modern production derives from digital recording. There are a few holding the all analog tradition alive but alas they are today the exception.

I believe there is general consensus that original editions - the likes of Mercury's, Deccas, RCAs, Lyritas, Blue Notes and many others - are highly valued for their better sonics over reissues. Those need to be preserved. That's not a knock on quality reissues, I been allowed to experience a lot of music I would not otherwise have if it were not for them. They too need to be preserved. I was so happy to see @Mike Lavigne take this up - he has a vast collection, maybe not all are 10's but many are of music we may never hear recorded again.

We vinylists should remind ourselves of this. We love building collections but we need to keep in mind that we, in the end, are curators for our time, hopefully passing those collections on to others who will love them as much as we love their music today. I believe we have an obligation to this curation and preservation and that keeping one's records clean is an integral part of owning vinyl. It is vital to the viability of our hobby.

When someone asks advice about getting into vinyl don't forget to tell them about keeping their records clean. Most fortunately technologies have been maturing over the past ten years to further this goal. We have made progress and will continue to further it - the knowledge is there, thanks to experts like Neil - we simply need to act upon it. Living La Vida Vinyl!

Let me echo an observation that I am now convinced of. Vinyl record playback up until the electrical signal is generated is essentially a musical instrument. Vinyl record playback is subject to many of the same variables as a music instrument and therefore each vinyl playback system; the combination of the table, platter, mat, record, stylus, cantilever, etc will playback differently. In the paper - Disc Phonograph Records by Dr. A. M. Max, RCA Engineer Magazine 1966-08-09 1966-08-09.pdf (worldradiohistory.com) Dr. Max shows that the record temporarily deforms during playback. So, in some sense, the cartridge is to the record like the bow is to the violin; and this makes vinyl playback absolutely unique; and of course, confounding.

Some of the ingredients in the records of yore would not be used today - safe in the record, but not safe for the pressing plants. Also, record quality was a corporate objective. And, sorry guys, but how many women are pictured in the final QC of records. It's a known fact today, that women are much better at those intricate type details than men. So, the records of yore can be very special.

Just some thoughts,

Neil

The paper also states that “…repeatedly-used damp pad or like device can become a positive menace.”

DiscWasher users take note. I was one a long time ago.

Critical Cleaning meet Critical ThinkingHowever, your conclusion that it is rinsed by the TDS measurement of the bath water is valid.

Neil, thank you as always for sharing your knowledge.

No - do not use Liquinox as a stylus cleaner. For a stylus cleaner you want something that will leave no residue. If your records are clean (and yours are) the only thing you should be removing is some fine powdery type dust and the occasional fiber.As an Onzow user currently being disabused of my trust in it, thanks to discussions over on Analog Planet, I’m now wondering whether there’s any application for Liquinox (Citranox too aggressive?) in stylus cleaning?

For the occasional fiber on the stylus I use this HEPA filter blower - Sensor Swab Ultra | Sensor Cleaning for DSLR and Mirrorless Cameras | Sensor Swab®, Cinema Sensor Cleaning (photosol.com); or you can use a very soft brush such as a red-sable paint brush.

For dust on the stylus, the standard short carbon fiber stylus brush Stylus brush, fibre (ortofon.com) works, and if you spray with a touch of DIW it can assist with cleaning. I have found if I place brush flat (fibers up) on the platter and control the tonearm to let the stylus just touch the brush, and then pull the brush (while flat on the platter) away from the stylus I can good control of the process.

However, the reports by Analog Planet on the ZeroDust may be premature. There is a lot of unknowns, and some reputable people are pushing back - check the thread at SH. Mikey uses a digital microscope to set his VTA and he is just now seeing this? What he is seeing could be cleaner residue or cleaner residue that reacted with the gel. I continue to use the ZeroDust I have for end-of-session play, but I am careful to let only the stylus touch the gel.

Neil

No - do not use Liquinox as a stylus cleaner. For a stylus cleaner you want something that will leave no residue. If your records are clean (and yours are) the only thing you should be removing is some fine powdery type dust and the occasional fiber.

For the occasional fiber on the stylus I use this HEPA filter blower - Sensor Swab Ultra | Sensor Cleaning for DSLR and Mirrorless Cameras | Sensor Swab®, Cinema Sensor Cleaning (photosol.com); or you can use a very soft brush such as a red-sable paint brush.

For dust on the stylus, the standard short carbon fiber stylus brush Stylus brush, fibre (ortofon.com) works, and if you spray with a touch of DIW it can assist with cleaning. I have found if I place brush flat (fibers up) on the platter and control the tonearm to let the stylus just touch the brush, and then pull the brush (while flat on the platter) away from the stylus I can good control of the process.

However, the reports by Analog Planet on the ZeroDust may be premature. There is a lot of unknowns, and some reputable people are pushing back - check the thread at SH. Mikey uses a digital microscope to set his VTA and he is just now seeing this? What he is seeing could be cleaner residue or cleaner residue that reacted with the gel. I continue to use the ZeroDust I have for end-of-session play, but I am careful to let only the stylus touch the gel.

Neil

My approach:

How do you clean your stylus?

I recently acquired a new cartridge. In the past I have been using a few different methods to clean my stylus, including the Last stylus cleaner fluid, the Onzow Zerodust bubble cleaner, a Flux HiFi electronic ultrasonic cleaner, and now SPT treatment. I was told by my dealer NOT to use the...

and follow-up:

How do you clean your stylus?

I also use the Magic Eraser, but I very gently rub the stylus sides from back to front once or twice and occasionally dip the stylus before each play. I follow this with a dip into the Onzow to remove any residue or white dust from the ME. Stylus looks brand new and I've never had a problem...

The work on the Onzow issue comes not from MF but from J.R.Boisclair of Wally Tools. He has v high powered non-digital microscopes. I never have cared for the gel type stuff.

I assume 'SH' means Steve Hoffman forum - Neil do you have a link to the 'pushback' there?

Thanks for the advice on stylus cleaning. Very helpful. I do use a microscope for setup and have previously noticed some blobs left on the stylus but I never joined the dots between the Onzow and them. I recently have become a little dissatisfied with my replay and couldn't figure out what was causing the issue I was hearing. When the Analog Planet Onzow report came out I took another look under the microscope and everything JR@Wallytools talks about is now all over my stylus too. Still, this is just an anecdote of course and Neil is correct to say we need to reserve judgment until we have the facts, but it will be very interesting to see how this plays out. Anyway, I did a non-Onzow clean (Flux "ultrasonic") on it to remove the crud and now the MAGIC is back. For now, my Onzow is off-limits leaving me with the urgent problem of gathering the tools for a new stylus cleaning regime.

How do you clean your stylus?

Is it too old school to clean the stylus just by gently sweeping the hard bristle brush from back to front? And occasionally a bit of Last Stylus Cleaner? Does it have to be any more complicated than this? No

I have no problem with the disucssion thus far on stylus cleaning among the regulars on this thread - thanks for your contributions. I don't want the thread to swerve into a general discusion about Onzow or stylus cleaning. WBF has a good thread for stylus cleaning and there are pointers to it above and in my prior post. I'm a fan of keeping relevant information together. Thanks for your consideration.

fDin - I will follow up on yr post there.

Tim:I assume 'SH' means Steve Hoffman forum - Neil do you have a link to the 'pushback' there?

Analog Planet on the Zero Dust | Page 6 | Steve Hoffman Music Forums, read posts #129, watch video posted #131 noting the discussion comes up at 1:02 and note commentary of post #132.

Neil

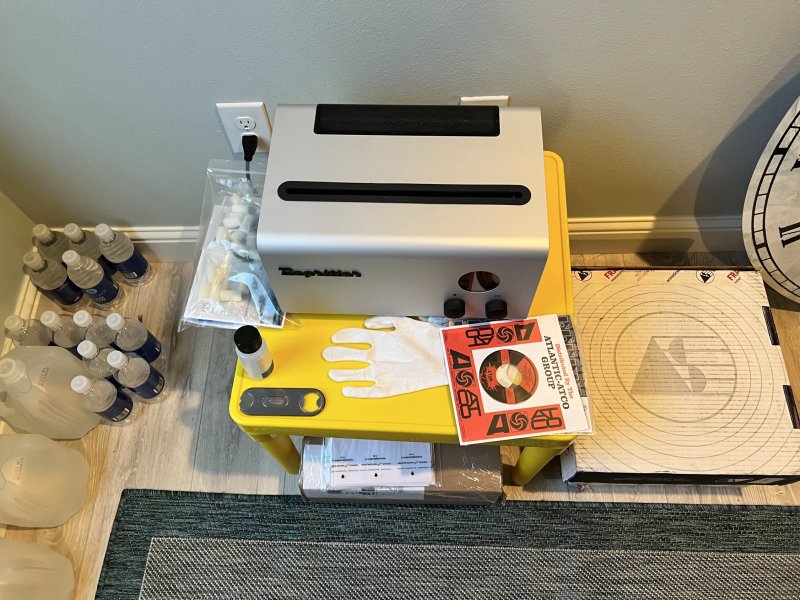

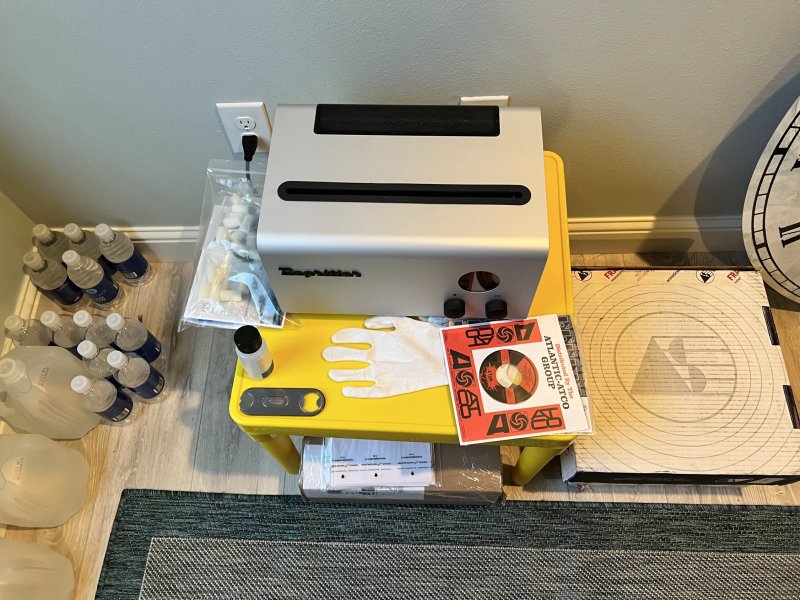

This is really great, thank you for postingAll parts purchased in USA.

Pump - the pump, it is a Little Giant 1-AA-OM model that is no longer offered by the Little Giant company, but several vendors have surplus inventory. It is a sturdy little industrial quality pump that was used in hot liquid drink dispensers. Because it was wired into a machine, you will need to add a cord (wire and a plug) to connect it to an electrical socket. Fwiw, I looked at using aquarium pumps; most were too noisey or too cheaply made, or meant to be submersed.

1 Little Giant 1-AA-OM, 531001 In-Line Pump, 115Volt LG1-AA-OM

Purchased from www.pumpvendor.com. There are other vendors.

I don't remember the thread dimensions on the intake and outflow. You should be able to find specs at the vendor or Little Giant. I used a nylon hose barb on the intake and a brass hose barb on the out. The intake is threaded on the inside and outside, so it can handle two different sizes.

Pump Box - Cantex Industries #5133710U 6x6x4 PVC Junction Box. I drilled/reamed holes in the box for: hose from USC, hose to filter, electrical cord, and mounting the pump to the base of the box. One hole in the box lid to mate with the output. I put small stick-on bumpers on the bottom of the pump so it wouldn't rattle, used small bolts and nuts to hold it to the bottom of the box. I put the same sort of bumpers on the bottom of the box to give it a little clearance with those bolts. I drilled several small holes in the box on the side where the pump's fan is mounted for air flow. Check the picture below you can see most of the details. It may sound complicated, but if you have the pump and box in hand, you'll see what needs to be done. Took me maybe two hours to complete once all parts were in hand. It is quiet in operation.

0.35 micron Filter - Flow Max FM-0.35-975 2-1/2” x 9-3/4” aka 10" (half the price amazon wants here)

Cannister - Pentek 158116 ¼” #10 Slim Line. There is a plastic wrench (recommended) available for these but I don't have a part number. You can buy the cannister with different size thread holes. I used 1/4-inch and brass hose barbs.

Tubing3/8? intake from the USC and 1/4? output to the filter and back to the USC.

Here's a picture:

View attachment 44066

note: this shows a small cannister and 1 micron filter, not the newer setup for .35 micron 10" filter , but you get the idea.

This is really great, thank you for posting

You're welcome, Michael. I've come further since that post and my DIY RCM has evolved:

Here is a parts list for the above:

tima's DIY RCM

FWIW, I use Zippo, primarily to remove stickers from sleeves, but it works wonders on paint and other similar substances. It evaporates very quickly, however, so there is no ability to soak. Where does this paint even come from?!

More pictures and info on surfactant:

tima's DIY RCM

I bought the 3ml Calibrated Eye Dropper pipettes Neil mentions, and 1 pint of Tergitol 15-S-9 from Talasonline.com ($21.75 + ship) The calibrated pipettes graduated in 1,2 and 3 ml are a perfect tool for adding Tergitol to a tank - very nice, thanks for the suggestion Neil. I emptied the tank of...

Feel free to ask questions, but also use search and browse the thread.

Similar threads

- Replies

- 3

- Views

- 865

- Replies

- 7

- Views

- 2K

- Replies

- 13

- Views

- 2K

- Replies

- 21

- Views

- 3K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |