Tim:

Not sure you noticed, but the motor slides up and down secured in-place with a knurled knob shown on Page 4 of 7 of the Viny Maid manual, it's the knob below the motor assembly. Now the Vinyl Maid manual says nothing about this in the setup but at the end Step 8 - Drying - Detach the record holder from the machine, if the space inside the ultrasonic cleaner doesn’t allow to remove the holder freely then lift the holder using the knob at the rear of the main pillar.

...

Neil - Not sure you saw this post.

I'd like to dig a bit further into the Vinyl Maid + Elmasonic P60 combination based on my experience with the Kuzma RD and Elmasonic P120. At this point I consider the VM + P60 combo as ... how shall I say this ... as hypothetical or theoretical. Why? We have no accounts from end-users of this combinations. That doesn't mean there are or are not such end-users, only we have not heard from anyone using it -- at least on this forum. Show me 5-10 end-users with 6 months experience with the VM+P60 and maybe we can all be better informed.

I suggest you read this post with the VM PDF manual open so you can see the photos of the machine to follow what I"m going to describe.

I am curious about the ergonomics of the VM+P60 combo.

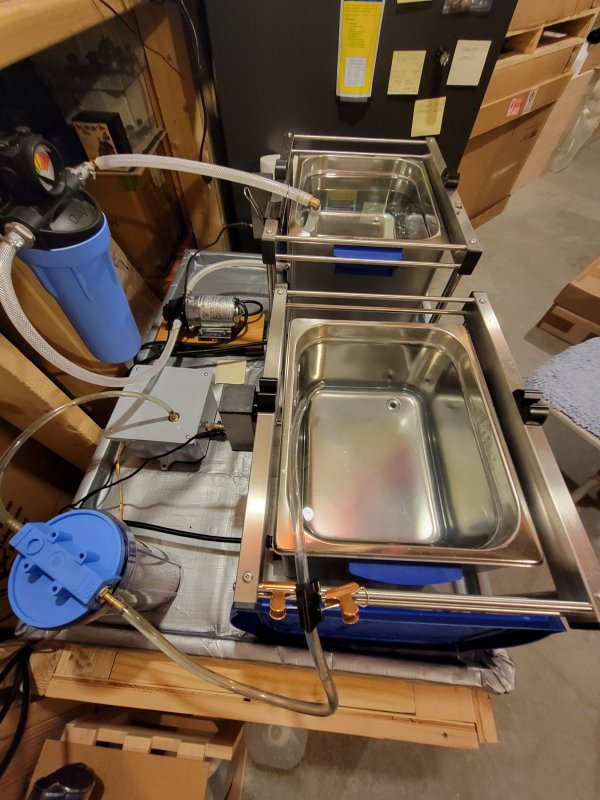

I"m not suggesting the VM will not fit the P60. The tank meets the minimum dimensional requirements of the VM (300mm H x 120mm W x 150mm D) tank, but it sure can not be any smaller. I'm not saying the combination can or can not work. I want to think about / dig in to practical use

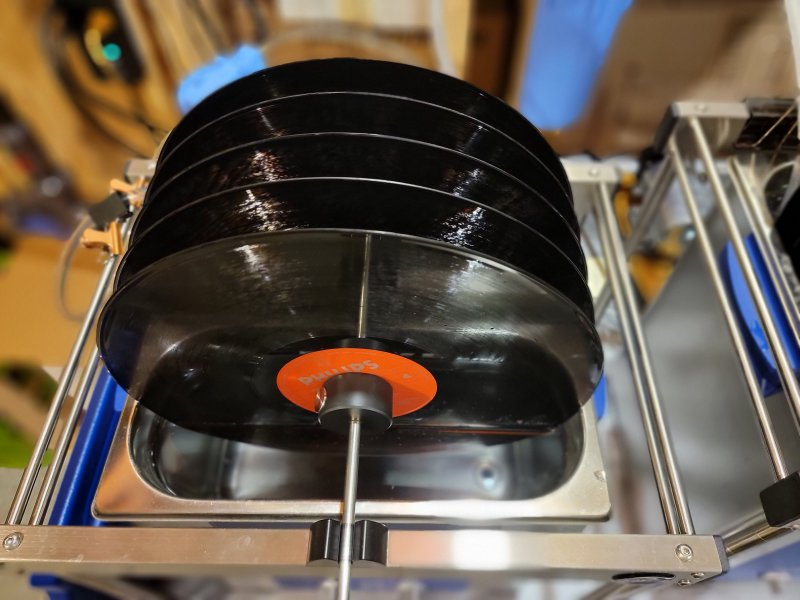

What I've learned using my own system is the relatively tight tolerances involved in physically positioning a tank with a rotisserie. Both the Elma units (P60 & P120) measure internal width at 300mm which is ~11.8 inches, with a vinyl record being 12" in width. For any rotisserie: 1) the spindle going through the record hole must sit above the rim of the tank. 2) Enough clearance is needed at the records edge/perimeter in the tank to clear the sides of the tank sufficient to wet the record to the edge of its runout area. The amount of runout varies record to record.

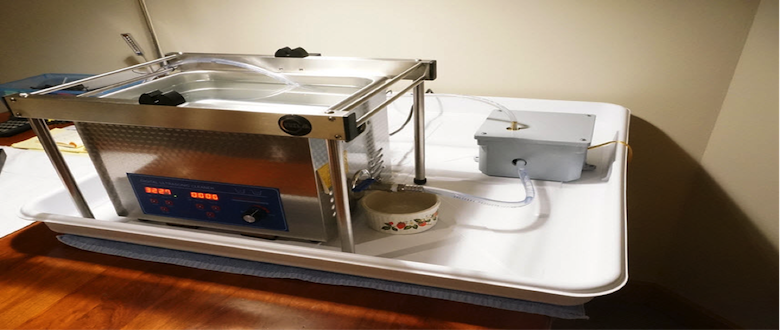

From pictures of the Vinyl Maid, the post holding its motor and magnetic coupler attaches to a plexiglass base and the UT sits on that base. That means a tank full of water must be exactly positioned relative to the motor / spindle, because once in position the tank, base and motor post are wedded to one another by the weight of the filled tank. Bear with me a bit longer ...

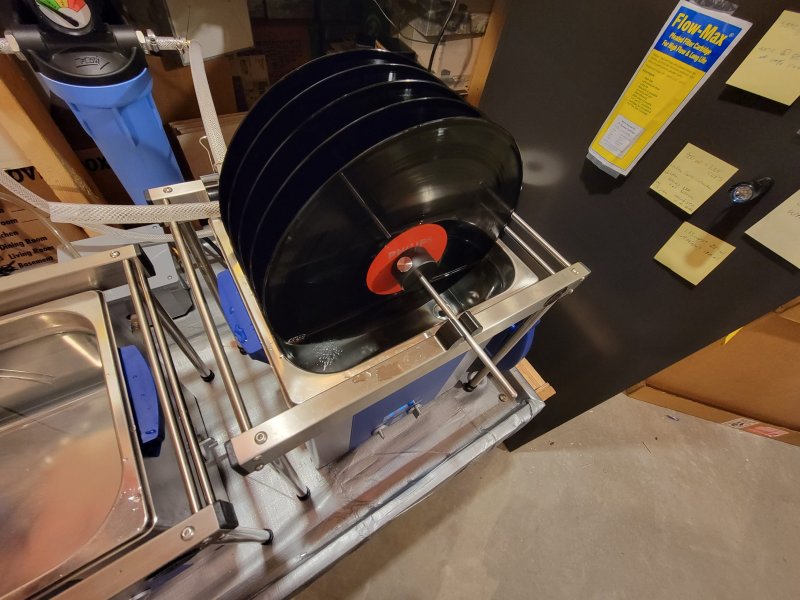

Given the above, I'd say forget about mounting 5 records, I believe the tolerances are too tight to yield the necessary space between the records edge and the two sidewalls of the tank to allow the records to spin freely. I'd say you want 1/16th of an inch between the record edge and a sidewall. And you want at least more than 1-inch between the records and between the end records and the front-rear tank walls. Elma tank corners are rounded. Note -- no picture on th VM Web site shows 5 records on its spindle in the tank, the max shown is 4.

Now. think about a VM spindle with a record load. (Loading it is an issue in itself that I can discuss in another post.) How will you hold the record loaded spindle? The spindle's screw-on knob is probably not big enough to hold it securely in with one hand so you'll hold the magnetic coupler with your other hand. With the motor unit at actual wash height you need to lower the records into the tank by hand and attach the spindle to the motor's magentic coupling. Again, the more records the more careful you need to be in doing this.

I"m thinking the VM motor unit needs to be raised to its full height for attaching the record holder, then lower the records into the tank. Loosen the post-height knob, raise the post, tighten the post-height knob to lock it in place. Then hold the records with the knob on the spindle, use the other hand to guide the magnetic couplings together. Still holding the spindle knob release the post-height knob and lower the records into the tank to the correct height to cover the groove area, then tighten the post height knob to lock the post in place. It would be good to examine the post height tightening knob to see how well it works and will it stand up over time to repeated tightening.

It may be possible to attach the magnetically coupled spindle to the fully raised post, and load records and separator discs in that position. What is unknown is the strength of the magnetic coupling. Is it strong enough such that it will not detach from the post by the slight jiggling that will occur while loading the spindle? Maybe that could work but I'd probably feel more secure loading the spindle while it is off the post.

Removal of the spindle of records is the reverse. Hold the spindle knob with one hand, release the post height knob with the other, raise the records out of the tank, tighten the post height knob, break the magnetic coupling to release the spindle from the post. If you will air dry the records and you're using only a single spindle, you could leave the records attached to the post and let them dry in place.

I'm thinking it could be much easier to go through the above with 2-3 records on the spindle. In Neil's suggestion of the P60+VM combination he likewise references using it for 2-3 records. For now I'm thinking it is an ergonomic over-reach each to assume cleaning 5 records with a P60 size tank. What do you think?