Hi Tim (and dminches),

Thanks for your follow-up.

Water comes out of the tank drain and goes to a splitter “Y” with two shut-offs. When running only one pump, the other circuit needs to be shut off to prevent back-flow into that circuit. This prevents air getting into the lines.

From the “Y”, two lines go to the two filters.

From the filters, two lines go to the two pumps.

From pump #1, a line returns to a second splitter "Y" and then to the tank return.

From pump #2, a line goes through to the radiator and then to the other side of the “Y” and the tank return. This enables only one return tube into the tank.

There is a third “Y” with shut-offs just after the second “Y” and before the tank return that provides access for a drain line to flush the system. (Before I added this feature, I was removing the “U” shaped tank return and I managed to hose down a row of books in the bookcase below!)

I run pump #1 while initially heating the water to 35 degrees and while running the Elmasonic. I shut the heater off before I start cleaning.

I run both pumps concurrently (open both sides of the first shut-off valve) to cool the water in both systems.

The kill-coils and the specified tubing prevent any (visible) algae or bacteria in the lines. They do get a black coating on the coils after a time and I may have to resort to cleaning them occasionally.

As far as my tics and pops go, I am getting very close. Previously, when I cleaned a used record I would run through the entire 40 minute ultrasonic and then the Loricraft, and then test play the record. Most times I would repeat the entire process a second time and the surface condition would be greatly improved and even more details revealed in the music.

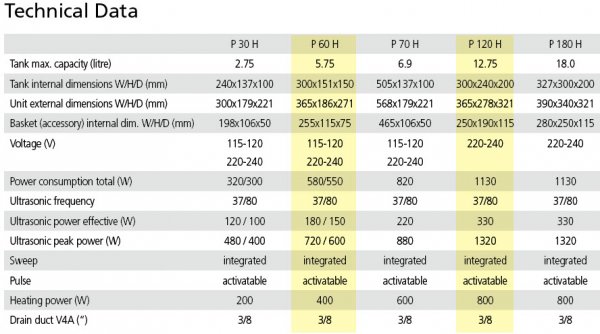

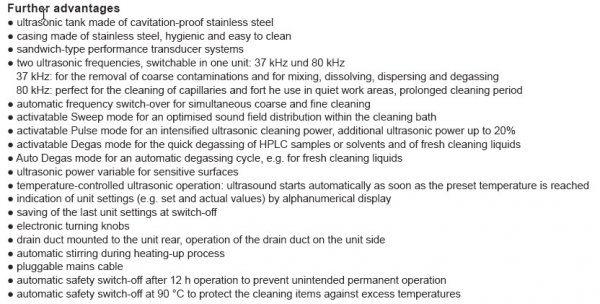

To get to the bottom of what was happening (Elma, or Loricraft, or playing the disc), I have been running a 60 minute cycle of 37/80 kHz followed by the Loricraft. So far, I have not felt the need to wash any records a second time! I will still use the 35-40 minute cycle for new or otherwise cleaned records.

Another approach might be to clean two records at a time instead of three for a shorter time. Two records seems to do a more thorough cleaning, but would also lower productivity.

Are you cleaning three at a time for only a 20 minute cycle? I forget, do you have the same Elmasonic P60H?

Maybe I will try the isopropyl (?? – I have a half case of Everclear left in the basement)

I hope that this description is more complete.

Best,

Don

Thanks for your follow-up.

Water comes out of the tank drain and goes to a splitter “Y” with two shut-offs. When running only one pump, the other circuit needs to be shut off to prevent back-flow into that circuit. This prevents air getting into the lines.

From the “Y”, two lines go to the two filters.

From the filters, two lines go to the two pumps.

From pump #1, a line returns to a second splitter "Y" and then to the tank return.

From pump #2, a line goes through to the radiator and then to the other side of the “Y” and the tank return. This enables only one return tube into the tank.

There is a third “Y” with shut-offs just after the second “Y” and before the tank return that provides access for a drain line to flush the system. (Before I added this feature, I was removing the “U” shaped tank return and I managed to hose down a row of books in the bookcase below!)

I run pump #1 while initially heating the water to 35 degrees and while running the Elmasonic. I shut the heater off before I start cleaning.

I run both pumps concurrently (open both sides of the first shut-off valve) to cool the water in both systems.

The kill-coils and the specified tubing prevent any (visible) algae or bacteria in the lines. They do get a black coating on the coils after a time and I may have to resort to cleaning them occasionally.

As far as my tics and pops go, I am getting very close. Previously, when I cleaned a used record I would run through the entire 40 minute ultrasonic and then the Loricraft, and then test play the record. Most times I would repeat the entire process a second time and the surface condition would be greatly improved and even more details revealed in the music.

To get to the bottom of what was happening (Elma, or Loricraft, or playing the disc), I have been running a 60 minute cycle of 37/80 kHz followed by the Loricraft. So far, I have not felt the need to wash any records a second time! I will still use the 35-40 minute cycle for new or otherwise cleaned records.

Another approach might be to clean two records at a time instead of three for a shorter time. Two records seems to do a more thorough cleaning, but would also lower productivity.

Are you cleaning three at a time for only a 20 minute cycle? I forget, do you have the same Elmasonic P60H?

Maybe I will try the isopropyl (?? – I have a half case of Everclear left in the basement)

I hope that this description is more complete.

Best,

Don