Thank-you so much taking the time to provide all the details. Lots of good information. I am not sure that what you were fighting is mold spores or paper (cellulose) that has broken down and essentially glued itself to the record. I have clean old-gray mildew from records with the manual sink process and have good results. However, I have a few records with what I call sleeve-rash were the paper sleeve has broken down (and the paper sleeves are not acid-free) and essentially etched the record surface. I may try a cellulose enzyme soak to see what happens. But cellulose is very difficult to break down, and industry does not use cellulose enzymes for this purpose. They tend to use very concentrated caustic (such as sodium hydroxide). I have thought of trying this, but I really have no interest of dealing with the safety issues.Here is the full information, including answers to your questions, and also what I got from listening to the records.

Answers:

Otherwise, when you were using the manual sink cleaning process with Liquinox and Citranox (that I have used as strong as 2%), were you getting lots of foam in the brush with the most with the Liquinox? Lots of foam in the brush is the tell-tale that the cleaner(s) are being agitated enough to get maximum cleaning.

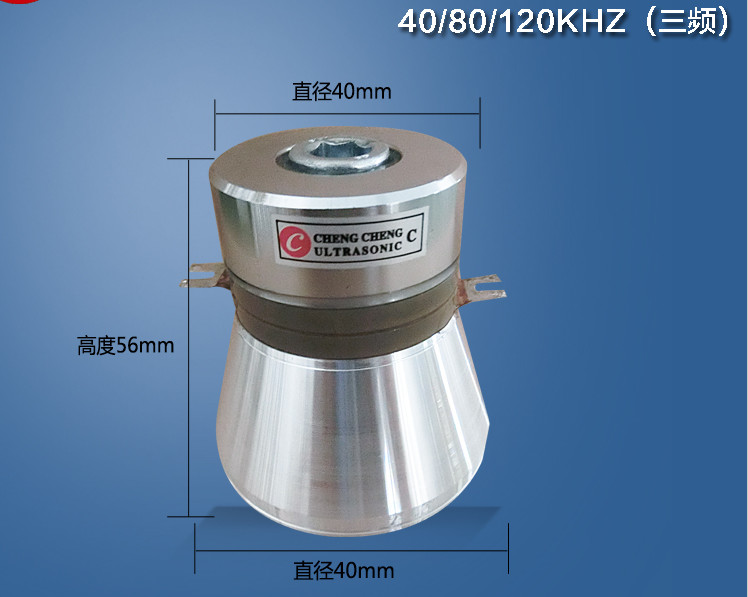

The problem with the high kHz machines such as https://www.cleanervinyl.com/multi-frequency-cleaners.html is that as I have written https://www.whatsbestforum.com/threads/ultrasonic-cavitation-cleaning-explained.36690/post-870704 as the kHz increases, the required power increases. There is some offset as the tank volume increases, but 120kHz needs a lot of power and a lot depends on whether the unit actually delivers the advertised power. Also, the 120-kHz is targeting particles below what the stylus can respond to, with 80-kHz being near ideal and at a lower kHz does not place the same power demands as 120-kHz. Also, although the tank can fit many records, it's easy to overload the tank so cleaning less records is better especially if you are trying to remove tenacious detritus. And, as I have written, the rotation speed can have a significant effect on cleaning performance, especially at <60-kHz were the flow generated can significantly reduce the cavitation intensity.I should also add that initially I was using an inexpensive USB that only had a 40 Khz sonication speed, but before I started using the cellulase I bought a better one that supports 40 Khz, 80 Khz, and 120 Khz, and still allows up to 18 discs to be sonicated at once in a 15L bath. With the cellulase, I ran about the first six cycles at 80 Khz and the last four cycles at 120 Khz. I did this because the literature for the USB said 40 Khz is best for particular matter like dust (which I had already cleaned off), 80 Khz was good for smaller particles like mold, and 120 Khz will produce sonication bubbles small enough to fit inside the grooves and help remove even chemical residues. I reasoned the mildew crap was down in the grooves and it might work best to get the force closer to the remaining stuff in the grooves as what was higher up in the grooves was eaten away. But that's purely a guess; it's just what I did.

Your observation is consistent with what was determined about 70-years ago - https://csumc.wisc.edu/wp-content/u...ecordings-Lemcoe-M.M.-Picket-A.G.-undated.pdf. The results of Fungi testing starts on page 42 and does discuss the risk of sleeve breakdown from fungi attack, and on page 44, summarizes the following for the standard vinyl record. Other record compounds such as Acetate, and Lacquer/Shellac were attacked.That supports my hypothesis that mold does not destroy vinyl and all you have to do is clean it effectively. But that takes a lot. What I did appears to clean it effectively.

After six months incubation, the disc specimens were examined by hand lens and microscope for

signs of deterioration and the following results obtained:

(1) Unfilled, unextended microgroove vinylite compound, containing lead stearate, carbon black and a dye. Fungi grew profusely on label and branched out over the disc surface. After cleaning, little, if any, etching caused by fungi could be observed. No embrittlement or loss of flexibility was noted. This material seems

to be resistant to deterioration induced by moisture or fungal activity. (Compound A).

(2) This material is the same as notes in (1) above with the omission of carbon black: It behaved exactly as did the previous specimen. As far as resistance to damage by high humidity and fungi, the unfilled, unextended microgroove vinylite compositions proved superior to the other formulations. (Compound B).

Again, thanks for the details, very informative!

Neil