Thank-you for adding the details of what worked for you, understanding that the book

https://thevinylpress.com/precision-aqueous-cleaning-of-vinyl-records-3rd-edition/ does address killing mold with hydrogen peroxide VIII.11.3 MOLD, and VIII.11.3.b The safest sporicidal solution that should be compatible with records to kill mold spores is simple hydrogen peroxide. The one disadvantage is kill-time; 3% = 2.5-hrs while 6% = 1-hr.

I would like to add, that when dealing with mold, a manual sink-method should be the first pre-clean step to minimize getting the mold airborne.

A couple of questions though and these are not criticisms, just trying to nail the details:

1. When you say mold, you specifically identify mildew; were the records dry or still wet?

2. When you did the manual sink method, did you use the acid and if so which one?

3. What were the record inner sleeves - where they paper or better-quality HDPE?

4. Using the 60X jewelers' loop, how were you able to distinguish mold from other detritus?

Again, thanks for sharing,

Neil

Here is the full information, including answers to your questions, and also what I got from listening to the records.

Answers:

1) The records started in a couple of cardboard boxes, bottom seams on the bottom of the box and hence basically on the cement floor. Water came into the basement, pretty shallow, maybe 1/4" or 1/2" and then went away, and the boxes remained undisturbed for three months. I then went in the basement and realized what had happened, and I turned the boxes on their sides so they could dry out a little bit, but I did not open the boxes. Six years later I opened the boxes and took the records out. Everything was dry after that period of time. Record jacket that did not have the cellophane on them were stuck together. But records that had the cellophane on them had trapped moisture inside for a long time and still got mildew. The mildew sometimes was blotchy on the covers. Inside, records with no inner sleeve were very bad with nildew and a very few seemed to have cardboard fibers stuck to the vinyl. If there was a paper sleeve, the mildew was equally bad but at least it came out of the jacket easily enough, or I could tear the jacket open and get it out. If there was a high-quality HDPE sleeve similar to mobile fidelity sleeves, on a very few records I couldn't see any mildew, but for the most part I could still see at least small patches of mildew. HDPE sleeves definitely helped, but could not actually prevent a mildew problem in this severe scenario. A few of the records were still sealed - and they still almost always had at least a touch of mildew on the inside. I think out of about 100 records so far, two records that happened to have been still sealed and also had HDPE inner sleeves survived "mildew-free", judging strictly by lack of odor on the vinyl and no visible patches of gray on the surface. This much was by simple visual inspection, the mildew was plain to see before any cleaning. Regarding dry or still wet - I didn't pull the records apart and immediately clean them. I pulled them apart and set them leaning against a wall in a corner for months before I actually started trying to clean them. If they weren't totally dry inside the box, they dried out over those months leaning loosely against the wall.

I am identifying mildew - it wasn't fuzzy, it was more or less grayish and everything had a musty smell if there was any mildew on it anywhere. It was dry - but any kind of fungal spores can remain viable a long time even in the absence of water. And the stuff actually has a "body" which is like tubes growing around, I'm sure you've seen electron micrographs. I suppose that as it becomes dessicated material in the cell walls remains, and if there were polysaccharies or such they get "crisp" and sort of cemented together. This is just conjecture on my part, though.

2) Using vinyl gloves, I initially used 95% isopropyl alcohol on cotton balls and lightly wiped the labels. The mildew and water had severely damaged some of the labels, but most looked OK after that light wiping. I did not press hard or scrub, it was just light wiping. I tried hard not to grab the record where there were patches of (old) mildew visible. Most of the mildew was towards one edge of each record, the edge that had been on the floor.

After wiping the labels on both sides of an album I waited a few seconds for the alcohol to evaporate, then Immediately put a label protector on, again trying not to disturb the mildew areas where the spores were, and went to the sink. I ran water over both sides of the record, not with so much force that it was splashing all over the place, again trying to keep the spores in the sink and going down the drain. That does not do a great job of dislodging visible patches of mildew. I ran the record brush around each side of the record several times to get rid of visible mildew. Then I cleaned with liquinox, then with citranox. When you ask, "Which one" was the acid, it was citranox at the recommended dilution. I was turning the record quite slowly, so the brush went over a particular spot maybe 30 times in each direction.

3) It was quite a varied group of records, a few with no inner sleeves, most with paper, some with original HDPE sleeves, such as Reference Recordings and Mobile Fidelity releases. I mentioned differences in rought appearance depending on sleeve type above.

4) With the jeweler's loupe, after the liquinox/citranox/distilled water rinse/dry, I looked at different areas of the record carefully. Of course there was nothing "loose" on the record surface any more at that point. I could not literally see "tubes" of mold at that low level of magnification, but what I could see was the grooves. Over most of the album the grooves simply looked black, maybe shiny and broken up where light was reflecting off them. But there would be areas of grooves that appeared brownish under the LED on the loupe. Where there was brown stuff in the grooves, I could follow it along the groove and see where it came to an end; and generally if there was that stuff in one groove, it was also in the adjacent groove. However, it was somewhat broken up, i.e. there might be some millimeters of groove with no brown stuff, then a millimeter or two of black "free" area, then more brown stuff. And on the opposite end of the record that had presumably been away from the floor, it was clear. Many of the records had only a few small areas of that stuff after the sink cleaning. On some, I couldn't even find any - but it's not possible to cover every square millimeter of a record with a 60x loupse, as you can imagine. Telling the difference between mildew in the grooves and other detritus in the grooves just by using a loupe probably isn't possible - but whatever it was, it looked pretty much the same on all the records where I found it.

One very interesting thing I noticed. After spraying the records with distilled water after the final tap water rinse, all areas of the record looked the same. But when I wiped it with the clean-room sponge you have recommended, it was obvious that not everything had come off. I have found that fingerprints look a certain way, But the mildew had often been on the record in visible wavy patterns when I removed the vinyl from the inner sleeve - I suppose the waviness corresponded to areas where moisture had remained for longer, or something. Anyway, after cleaning and wiping the records with the sponge, I could sometimes see the same wavy pattern in the moisture reflections off the record. And so I correlate what was remaining on the record with where the mildew had been.

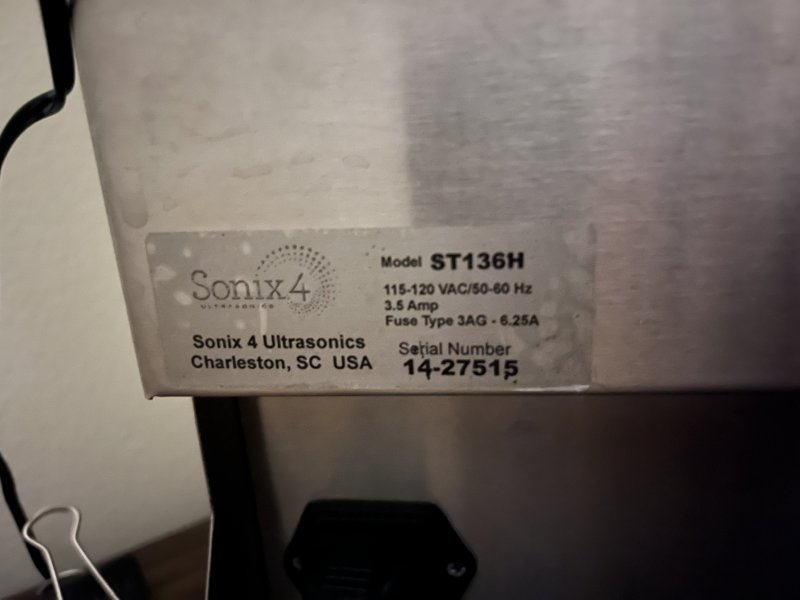

After I did that sink wash of quite a few records I saw they weren't coming clean but I was not really done anyway. I had already planned on treating them with hydrogen peroxide. I put them on the spindle ten at a time and put 3% hydrogen peroxide in the US in 1% ilfotol and just let them spin for a couple of hours. Then I turned on the sonication (40 Khz) for 15 minutes. After that I took them back to the sink and did another full round of liquinox on both sides and rinsed again. I looked closely at the records with a loupe again and some of the records seemed free of mildew (?) in the grooves at that point, and others did not. I didn't fully trust that any of them were fine because looking with a loupe is too limiting. I did separate them into two groups though. The hydrogen peroxide probably killed the mold, but it did not clear the dead stuff from the grooves.

I got some 4" x 14" x 14" plastic containers and soaked two still-dirty records overnight and then immediately ran them through the USC followed by liquinox again. I'd look at them and would often see there was still stuff in the grooves. The soaking did seem to help, but not enough. I tried the soaking followed by USC & liquinox on about 40 or records before I decided it wasn't helping enough and I definitely had to try something else.

At that point all the records from the two groups went back into the same mental grouping of "not cleaned well enough". I did not try to play any of them yet.