Ken,Neil,

that is very helpful indeed...thanks so much! With respect to the Polysorbate 20, is there only one grade suitable for all uses including cleaning records? Is there a recommended dilution for ultrasonic record cleaners and would I need a distilled water rinse after cleaning?

thanks again,

Ken

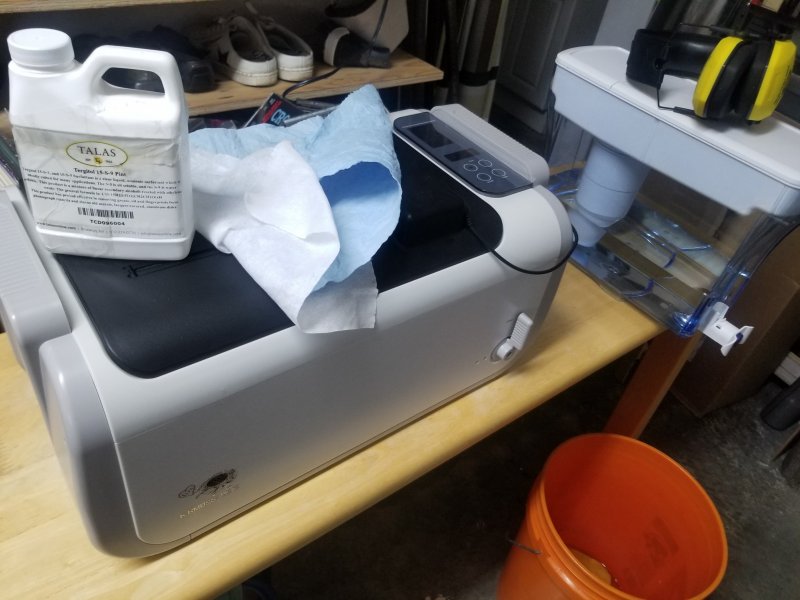

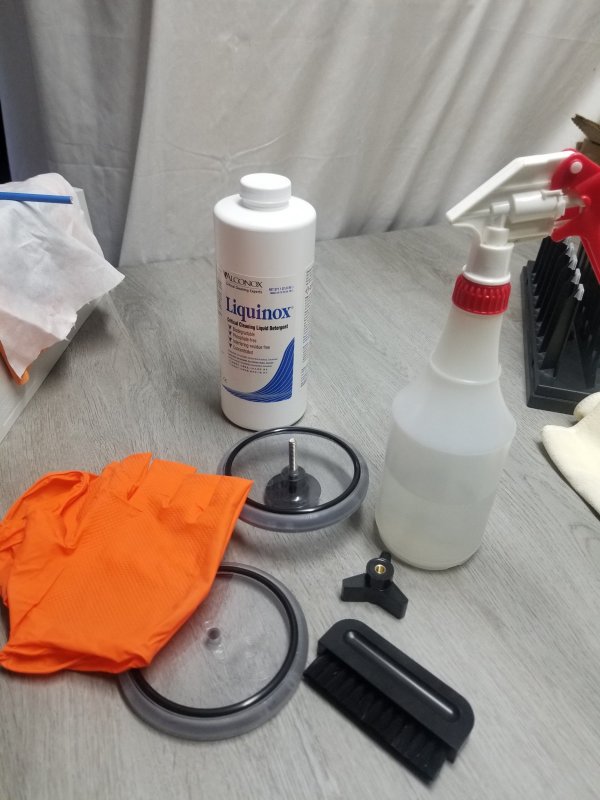

Whatever 'grade' of Polysorbate 20 you buy (food grade or cosmetic) will be fine for record cleaning. As far as dilution and use for the HG - do exactly what is specified for Tergitol 15-S-9 https://www.whatsbestforum.com/threads/humminguru-an-inexpensive-desktop-rcm.32074/post-786132. You are substituting Polysorbate 20 for Tergitol 15-S-9. Pick the concentration and the effect you want. If want only wetting you can skip the rinse, if you want detergency then you want to rinse.

Neil