I did move the Taiko Tana to underneath my NVS tt......and I've been listening for a few hours.

I'll bet that you are stunned.

I did move the Taiko Tana to underneath my NVS tt......and I've been listening for a few hours.

Maybe its time to come out and join the three Muskateers. I am number 4.

...

I did move the Taiko Tana to underneath my NVS tt......and I've been listening for a few hours.

We already changed the aluminum to stainless shelf for Chris for a reason, as Taiko Audio mentioned in his post panzerholtz can be too dead in this application Mike. The AS is very neutral and balanced by design I can't recommend introducing random resonance and dampening into the mix without some testing.

david

I don't know what the answer is, but Marc asks a fair question about what does it actually/exactly/precisely mean for the AVI to be in passive mode. Does passive mode result in a non-compliant steel plate sitting on a non-compliant steel shelf, or is there some spring tension or some other compliance in there somewhere?

(I would like to know the answer to this question for the TS-140, also.)

Taiko, so checking against yr list, the next best materials that gets closest to Panzerholz is rubber, cork and vinyl.

Really?

Maybe its time to come out and join the three Muskateers. I am number 4.

I asked David who is kind enough to collaborate with Jarek for a total solution of my Thor's Hammer. Jarek now has all design principles from David and also my requirements. It is a three tiers rack. High mass probably more than 400 lbs, functional oriented, no nonsenses. Second tier has Stacore Advance for my phono. The lowest tier is for the motor control. Active antivibe never enter my mind for this super heavy Hammer from the start. My listening room is also L-shape and the Hammer will be placed at the far right leg of L. Picture might better explain.

View attachment 37510

We just decided that the rack shall be no taller than 86 cm. Other design details and Jarek's secret sauce will be upto Jarek. Jarek can respond shall there be any questions. I dont know if this thread is appropriate. Here are some early rendering of the rack from Jarek.

View attachment 37511

View attachment 37512

View attachment 37513

Pls dont ask me about pricing. I only agreed with Jarek on pricing principals. In fact, we still dont know how much it will be.

Just to let you guys know Jarek has been working on his rack that incorporates his Stacore platform for general purpose. My rack is spec specifically for the AS so the structure could be different. Hope Jarek is not upset me showing his prototye.

Isnt this great we have different ways approaching the endgame tt.

Kind regards,

Tang

But Taiko, your Panzerholz has a DF of 0.7 and T of 1.5.

Based on those figures, those compliant materials do seem to be the closest ie rubber DF 0.3 T 2.5.

Maybe its time to come out and join the three Muskateers. I am number 4.

I asked David who is kind enough to collaborate with Jarek for a total solution of my Thor's Hammer. Jarek now has all design principles from David and also my requirements. It is a three tiers rack. High mass probably more than 400 lbs, functional oriented, no nonsenses. Second tier has Stacore Advance for my phono. The lowest tier is for the motor control. Active antivibe never enter my mind for this super heavy Hammer from the start....

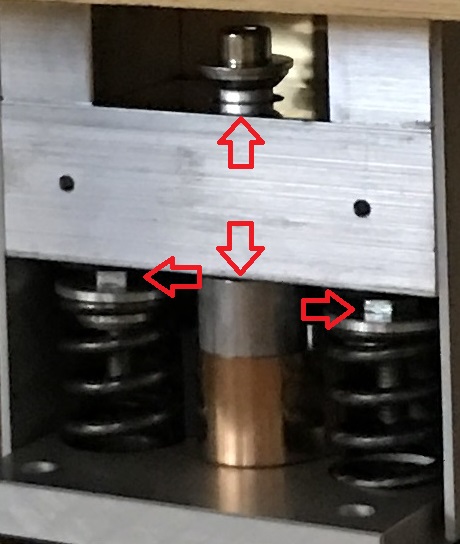

Photo of an AVI-200:

View attachment 37517

After you've loaded the AVI's you have to manually adjust the springs (left & right arrows) so that the platform is "floating" between the "stops" (up and down arrows). If you disable active correction it's easy to see you now have a passive platform sitting on springs.

For passive platforms you have a resonance frequency, for the AVI-200 this will be somewhere in the vicinity of 8Hz (the frequency will vary slightly depending on mounted platform, mass loading etc).

What this means is:

-Below 8Hz its a passthrough

-At 8Hz it will amplify

-Above 8Hz it will damp/isolate

If you enable active isolation it will fully compensate its resonance frequency, this is something ONLY active correction can do, you cannot break the laws of nature passively, and it will greatly increase and extend damping from below 1Hz to over 100Hz.

Now despite the AVI's having the exact same motors, sensors and technology inside, they do not quite reach the same performance level of the integrated units, however this, I'm sure, is due to the superior rigidity of the cast iron case encompassing the whole system in the TS line. Do not underestimate the rigidity of the platform and structure required to get stable Low Frequency performance. 1" thick aluminium is the BARE minimum here.

On the other hand it has some advantages too, it's slightly cheaper, the controller and power supplies are in external enclosure, you can also get an external controller which can power multiple AVI's at minimal upcharge. There's an external sensor option (LFE-3) which can increase ULF isolation to beyond what a TS can do (in theory). And I think it even has a LPS inside in stead of a SMPS.

We did however not manage to quite get the AVI to perform at the same level of the TS series.

congrats Tang! i'm happy it's you. figured it was either you or Jack's brother.....but with the AF0 direction there, figured you were #1 candidate.....with a bullet.

going to be a fun ride down this road!!

What is your opinion of the carbon steel plate on top of the AVI units such as I have ordered for my Nano Damp NDW workstation ?

Structural integrity / stifness is most important here, if it bends or warps you lose much if not all of the benefits. What is the thickness / who is supplying this? If either herzan or tablestable are supplying it you can rest easy as they know whats required.

What is your opinion of the carbon steel plate on top of the AVI units such as I have ordered for my Nano Damp NDW workstation ?

Structural integrity / stifness is most important here, if it bends or warps you lose much if not all of the benefits. What is the thickness / who is supplying this? If either herzan or tablestable are supplying it you can rest easy as they know whats required.

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |