I ordered the .35 micron filters and a holder as an upgrade thanks to Tima.

Tima, it would be great if you did a small guide on all filtration/pump parts. For example I noticed when buying these upgrade parts that the #10 holder says it's for a 10x2.5" but the filters are 9.75x2.75" but we know they fit because you use. But for someone unfamiliar this stuff can be very confusing. Also information on fittings etc might be nice. Just in general, I think it'd help people dive in.

Sure. Sorry for the length.

For starters, see post

#7 . It lists major parts with some discussion on building the pump.

Next - In my

first article about building my original system (on The Vinyl Press ) is discussion and pictures for assembling the Kuzma RD and some other elements.

Here are more details:

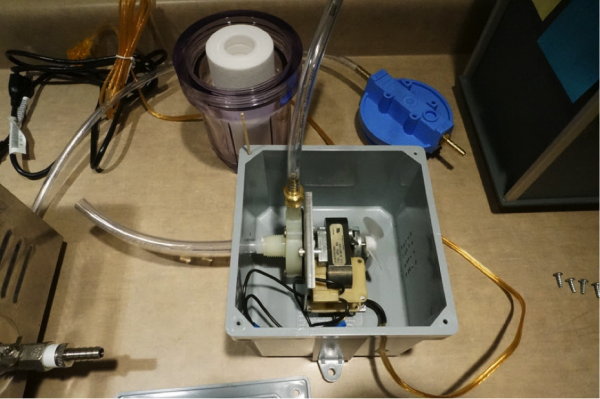

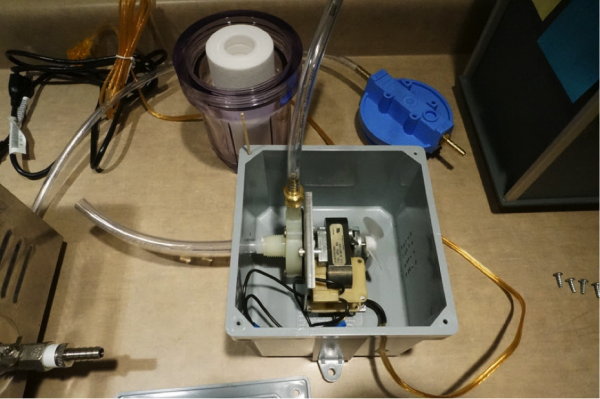

The Cantex PVC junction box use to hold the pump has thick walls. I started the holes with a drill, gradually increasing bit size and then used a manual reamer to open the holes to the needed size.

General Tools 130 T-handle Reamer $8

amazon

I wired the pump with lamp cord that had a inline on-off switch..

Westinghouse Lamp Cord 8 foot with rotary switch $7.30

amazon

For the Pentek 158116 ¼” #10 Slim Line, the "1/4" is the size of female intake and discharge fittings. There are a variety of 10" housings (cannisters) from Pentek, some with pressure relief valves. The clear cannisters are the least expensive, the solid blue cannisters can handle higher pressures and are more costly.

The filter industry has its own ways and are not always specific as to what fits what - as you discovered. For smaller applications, filter cannister sizes are typically 10" (#10) or 20" (#20). And filters to fit those cannisters can range, for the #10" from 9.75" to 10" in length; for #20 the same thing ranging from 19.5" to 20". Diameters also vary. If you talk to water filtration people and say I need a filter for a #10 cannister, they will know what you mean. But yeah, approaching this for the first time is like with many trades, they have their own guild speak.

It's worth noting that filters can have different end cap types. The kind we are looking for are specified 'DOE' for double open ended. For brevity, I won't go into other style end caps.

Filter ratings are another specification to be aware of. In simple terms, filter ratings or filter grade tells you the smallest particle size (in microns) that the filter

can separate out of the solution. Be aware the rating is considered either

nominal or

absolute which speaks to efficiency. A nominal rating says something like 'NN% of 1 micron" eg. 90% of 1 micron and larger particles are captured or prevented from passing through the filter. An absolute rating is a cut-off point or the largest diameter particle that

will pass through the filter, iln effect the 'exact' consistent pore size of the filter.

Typically (but not always) if a filter does not specify as absolute then it is nominally rated. Many cheaper filters have minimal specifications. ---> The 0.35 micron Flow Max FM-0.35-975 2-1/2” x 9-3/4” filter has a nominal rating. Roughly, it should remove most particles greater than 5 microns.<--- The micron number for nominal rated filters is relative. Typically absolute rated filters are more expensive and you can sometimes gauge what you have by its price. As Neal Antin taught me, ideally what you want is a

datasheet (spec sheet, cut sheet) for a filter.

Other components include fittings (hose barbs) and tubing. Hose barbs (and plumbing fittings generally) also have their own language. Relevant to our discussion there is a

barb size described in terms of the inside diameter (ID) of the tubing that attaches to the barb. And there is a

thread size for the threaded intake or discharge into or onto which the barb is attached. These can be threaded Male or Female. MNPT means male threads, FNPT is female threads - these are preceded by a size, inches for the US system. For example 1/2" MNPT x 3/8" barb means a hose barb with 1/2" threads that will fit into a 1/2" female and attach a hose with an inside diameter of 3/8". You need to pay attention to these and they vary across the filtration system. You cannot measure openings with a ruler, so go by product specifications.

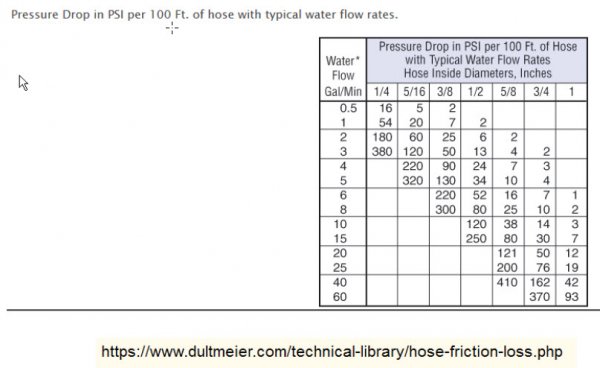

In the system described here I use 3/8" tubing from tank to pump and 1/4" tubing everywhere else.

Discharge from tank: this depends on the specific tank you use and the tubing size you will run to the pump. Typically these have a valve to control shutoff and a female fitting. Try to get specification on fitting size from the manufacturer or vendor before you buy. Instructions may not include the information.

Intake to pump: the Little Giant 1-AA-OM pump offers both a 1/4" Female fitting or 1/2" Male intake fitting. I used the Female threaded intake and chose a 1/4" MNPT (male national standard pipe thread) to 3/8" hose barb made from Nylon.

Discharge from pump: pump fitting is 1/4" male. I chose a 1/4" FNPT to 1/4" brass hose barb.

Intake and Discharge of filter cannister: these are identical. Cannister cap has 1/4" female fittings and I chose 1/4" MNPT to 1/4" hose barb in brass.

I suggest using nylon plumbers tape on all threaded fittings. The fitment size of hose barbs can sometimes determine choice of hose barb material (brass, stainless, nylon, etc.) Not every fitting combination is available. I did not need hose clamps, but be prepared to use them if you have leaks.

Snag this picture and enlarge it on your computer. You should be able to see all 5 hose barbs.

There is the whole topic of matching the right pump to the application which includes filter, tubing, head, flow rate, pressure, etc.etc. It is kinda complex at first and I will not go into that here. Suffice it to say my DIY pump/filter system works as described in this thread and in my articles on TVP.

To be forthcoming: I am in the process of changing my filtration system to use an absolute rated 0.2 micron filter with a claimed efficiency of 99.98%. (PDF datasheet

here) The type of filter should have a much longer lifespan in my DIY RCM system. And, as it turns out, doing so is much more complicated than just dropping a 10" different cartridge into my cannister. It means basically an entirely new set of filtration components: filter, cannister, pump, tubing, hose barbs, etc. I have it built, but not evaluated yet. A complete report will be published sometime this year. This does nothing to invalidate the filter system we discussed here.