I just wonder, how the Degritter could be offered to a that lower price!

There are relatively inexpensive 120-kHz transducers readily available from China. Otherwise, there is a big difference between a consumer product and an industrial product. For the Degritter which is a very compact unit with on-board power supply, from readers reports the average mean time between failure (MTBF) is about 4500-records cleaned which at a total cleaning/dry cycle of average 20-min (0.33-hrs) = a MTBF of (4500-record)(0.33-hrs/record) = rounding up 1,500-hrs. In the industrial world, the MTBF is measured in 10,000's of hours.

That means I have only ,8 cm to the edge of the record on both sides and to take care. Correct?

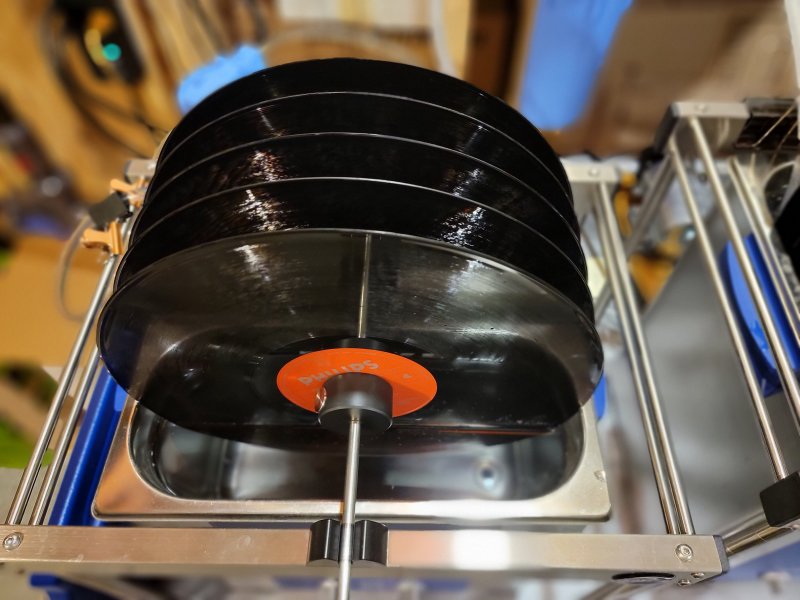

When you clean with UT, you clean only to the run-out groove to avoid wetting the label which would measure about 11-inch/280-mm, which would leave 10-mm on either side and that is enough clearance as is 8-mm, noting that this clearance is at the very edge - see

@tima setup

https://www.whatsbestforum.com/threads/timas-diy-rcm.26013/post-902552.

As I read your whole thread, which is great, I understood the ratio between needed power and removal efficiency. But if I would be O.K. using much more power, would the cleaning effect not be better? (I am just curious why the Degritter by decision uses 120 kHz and why the only professional record cleaning service PVF uses additionally 125 kHz and 220 kHz.) My stylus cut is sharp and I suppose the mid and deep area of the groove could have a benefit. Feel free to tell me if I am wrong. It is just my idea to start cleaning/rinsing with 37 and 80 kHz and as next steps going higher.

First, as the figure in my first post shows, each range of kHz targets some soils better than others. The Degritter with 120-kHz does not clean fingerprints very well without use of some chemistry to assist. If you are cleaning a dirty used record, you need to do some form of pre-clean before final cleaning with a high (>60-kHz) frequency UT tank. Also, bear in mind that as the kHz increases, the noise decreases. But consider that the KLAudio only uses 40-kHz but its 200-watts into only about 0.7-L, while the Degritter is 120-kHz and 300-watts into 1.4-L. The KLAudio will produce much greater cavitation intensity and what it lacks in cavitation bubble size, it makes up with brute power enough that if the record was to spin too slowly, it could be damaged. On thing to consider when cleaning a record is that there are no inaccessible areas - there are no blind holes, cross-drilled passages, etc. From a precision cleaning perspective, cleaning a record is easy.

But the existential question is how clean does the record need to be and can you achieve that in a normal residential environment? Chapters XI and XII make an attempt to answer those questions. The record surface roughness is reported at about 0.01-micron, and the smallest recorded modulation is 0.1-micron (and these are not common). Cleaning below these levels achieves nothing, it's below the threshold of audible impact and this assumes you have the environment that can support achieving the sub-micron cleanliness levels.

First, the best reasonable readily available UT bath filtration system you can install is about 0.2-micron absolute (the book Chapter XIV goes into detail on filtration systems). Attempting to filter below this level will incur considerable cost if you as a consumer can buy it. But it you are cleaning to less than 0.1 micron, if the bath water is not similarly clean - what's the use?

Second, for records, the 800-lb gorilla is after you cleaned the record, how do you dry it and keep it clean without you, the record sleeve and the ambient air environment re-contaminating it. The most basic Fed-Std-209, Class 100,000 cleanroom has a requirement of 100,000 particles >0.5 microns/ft³ of air, and 700 particles >5 microns/ft³. You can achieve a reasonably clean area in your home, and locating a HEPA filter in the area can help. But, between you which from a cleanroom standard at your cleanest is still dirty and your ambient air, your environment does not come close to even the most basic Class 100,000 cleanroom. Of course, you can dry the records in a HEPA filtered oven - they are readily available. But, then after all this cleaning, you slip that record into a record sleeve that is nowhere near as clean, and then you place the record on the platter that is nowhere near as clean. And let's not even talk about the ubiquitous carbon-fiber brush.

So, from my pragmatic engineering and technical perspective, for record cleaning I see no realistic cleaning benefit from more than 80-kHz. So why use a very high kHz UT machines for final clean? First, they are quieter, and second there is always the marketing aspect to set yourself apart from the commonly used 35-40-kHz.

However, after all is said and done, my philosophy when it comes to everything audio is that What's Best is What's Best for You! Otherwise, when I assist someone with their cleaning process, it's getting the bests results for what's best for you be it a strictly manual cleaning process as I address in the book where we can use chemistry you would not use elsewhere (but the results are subject to your technique and do not support high throughput) or maybe it's strictly vacuum-RCM which is really a machine assisted manual cleaning process (discussed Chapter XIII) or maybe its UT with the many variations it offers or maybe it's a combination of vacuum-RCM pre-clean and final clean-UT.

Take care & good luck,

Neil

www.ultraschall-anlagen.de

www.ultraschall-anlagen.de