Exclusive P3…there is a mint condition one for sale now in Italy.… I know very little about that TT, the model and the table itself… also I really want to take my time and not go for the quick occasion, there‘s no rush as my Brinkmann is fine and I want to see where any alternatives may get me… of course a used TT can be an option, but I need to figure out what I really want first…

Belt Drive vs Direct Drive and which one?

- Thread starter skinnyfla

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

… what has, the asking price for a used Melco TT?doubled in price in a couple of years

the double comment was for the Exclusive 3 in Italy… what has, the asking price for a used Melco TT?

here´s the Melco...same platter, bearing, motor unit and Jaap Pees powersupply like mine

this has top of the line original 50kg plinth

mine is custom 4 tower ss316 65kg plinth

Melco 3560 incl. sep. PSU, optional FR-66s & DaVa Reference field coil cartridge with tube PSU

Due to changed priorities I am offering my Melco 3560 for sale. Included is a dedicated brand new PSU made by Jaap Pees. On request and for additional surcharge I can offer FR-66s tonearm with VTA adjustable BA 60 arm base. Also for sale I have...

If you still can arrange the Schick demo, might as well try and meet Schröder as well if he is available. After all that perhaps Martion would be open to demo his active horn speakers? There is a lot of interesting audio in Berlin!... really kinda forgot about this - next time I`m in Berlin I´ll see if I can get to visit... I`ll let you know

Sorry, I meant Tech DAS in the AFO but does not reflect on Tech DAS for the reason stated below. I was merely referring to the beautiful motor they use They, and several others use the biggest motor from Pabst. These are superb, but as built had a fatal flaw. Used by the hundreds in old professional machines I mentioned they all fail. The reason for this is that the enamel used on the coil wire as insulation in the motor coils tends to crack with time and fall off in pieces. The result is a mortal short. Most modern builders get around this by totally rebuilding the motor before use. Karmelli I think does as does TechDas. Both are way too professional not to do so. One may however come across a homebuilt or lesser brand that does not do so and like me, then sit with a boxful of beautiful bricks.Could you tell us more about this comment?

Last edited:

When you're in Berlin , buy this a Raven with 3 motors my tip... really kinda forgot about this - next time I`m in Berlin I´ll see if I can get to visit... I`ll let you know

TW-Acustic Raven LS höchste Ausbaustufe (3 Motoren, großer Plattenteller!) (737789180) | Gebrauchtgerät | Plattenspieler-Laufwerk | Angebot auf audio-markt.de

Angeboten wird „Raven LS höchste Ausbaustufe (3 Motoren, großer Plattenteller!)“ von TW-Acustic als Gebrauchtgerät aus der Kategorie „Plattenspieler-Laufwerk“ bei audio-markt.de - dem Online-Marktplatz für High-End. Das Inserat mit der Nummer 737789180 endet am 12.03.2024 um 19:30 Uhr.

According to my experience and turntables that I measured, direct drive's wow&flutter performance isn't better than belt drive. Basic and very cheap direct drives can be very good up to a certain point but after that even high end direct drives can not improve w&f figures much further. Another strange thing that some modern direct drives offer worse performance than old, vintage ones. The best w&f results can be achieved with top belt drives according to my experience. I haven’t measure modern idlers but old ones are not far behind of direct drives.

Belt drive’s problem is belt, direct drive and idler’s problem is not being able to separate motor from the plinth (there are some exceptions like Esoteric T1). Direct drive motors have another disadvantage like turning at platter speed (33.3rpm). Idler's disadvantage is noise because of idler mechanism.

IMHO/IME there are more important factors than drive type which makes a turntable sound good or bad. One of those factors is high mass platter. A high mass platter (preferably over 20kg) is the key factor for a good sounding turntable and helps solving problems introduced by drive type (BD, DD or idler). I believe implementation and how good a turntable is built is more important than drive type.

Keeping steady speed at 33.3rpm and w&f performance are two different things. Another very important problem for all drive types is aggressively trying to keep 33.3rpm speed by control electronics. That aggressive control may achieve 33.3rpm average but for the cost of increased w&f. Piano and violin sounds are very sensitive to w&f. It's a good idea to check how piano and violin sound when evaluating a turntable.

Belt drive’s problem is belt, direct drive and idler’s problem is not being able to separate motor from the plinth (there are some exceptions like Esoteric T1). Direct drive motors have another disadvantage like turning at platter speed (33.3rpm). Idler's disadvantage is noise because of idler mechanism.

IMHO/IME there are more important factors than drive type which makes a turntable sound good or bad. One of those factors is high mass platter. A high mass platter (preferably over 20kg) is the key factor for a good sounding turntable and helps solving problems introduced by drive type (BD, DD or idler). I believe implementation and how good a turntable is built is more important than drive type.

Keeping steady speed at 33.3rpm and w&f performance are two different things. Another very important problem for all drive types is aggressively trying to keep 33.3rpm speed by control electronics. That aggressive control may achieve 33.3rpm average but for the cost of increased w&f. Piano and violin sounds are very sensitive to w&f. It's a good idea to check how piano and violin sound when evaluating a turntable.

Last edited:

the Melco has 35Kg platter...main mass in outer perifery, fantastic bearing, silk tread to motor pulley....motor starts up strong to get mass moving and after 20+seconds it goes into just maintaining rotation...very quiet.....when listening to plinth with stetoscope it´s absolutely no sound from bearing...pitch stability is fantastic

According to my experience and turntables that I measured, direct drive's wow&flutter performance isn't better than belt drive. Basic and very cheap direct drives can be very good up to a certain point but after that even high end direct drives can not improve w&f figures much further. Another strange thing that some modern direct drives offer worse performance than old, vintage ones. The best w&f results can be achieved with top belt drives according to my experience. I haven’t measure modern idlers but old ones are not far behind of direct drives.

Belt drive’s problem is belt, direct drive and idler’s problem is not being able to separate motor from the plinth (there are some exceptions like Esoteric T1). Direct drive motors have another disadvantage like turning at platter speed (33.3rpm). Idler's disadvantage is noise because of idler mechanism.

IMHO/IME there are more important factors than drive type which makes a turntable sound good or bad. One of those factors is high mass platter. A high mass platter (preferably over 20kg) is the key factor for a good sounding turntable and helps solving problems introduced by drive type (BD, DD or idler). I believe implementation and how good a turntable is built is more important than drive type.

Keeping steady speed at 33.3rpm and w&f performance are two different things. Another very important problem for all drive types is aggressively trying to keep 33.3rpm speed by control electronics. That aggressive control may achieve 33.3rpm average but for the cost of increased w&f. Piano and violin sounds are very sensitive to w&f. It's a good idea to check how piano and violin sound when evaluating a turntable.

Wonderful post Mtemur. I remember being surprised reading the W&F measurements in I think HiFi+ of the Air Force one and the SME 30. They were very low and I think the best turntables in this regard that the magazine had measured.

I agree that a high mass platter and build quality are the key factors but also how are the motor controls the platter and the speed control electronics themselves. If the motor pulley is able to maintain constant speed without constant correction, aided by a fly wheel and heavy mass platter with very low bearing friction, speed stability and consistency should be very accurate.

I have found through experimentation that the less influence the motor has on the platter the better. Separation and isolation helps, but so does a very light touch between driving pulley and platter. My thin non-stretch reinforced thread is quite loose. My platter weighs 65kg, and it floats on air. Speed might change from 33.333 to 33.334 on the RoadRunner Tachometer. And as you say, violin and piano, the complete note from attack to decay makes speed consistency quite easy to hear. Clarity, especially in bass and overall nuance also improve.

33.3 is pretty easy to achieve. 33.33 or 33.333 is more difficult. I would like to see studies about what is actually audible.

Last edited:

https://www.stereo.de/hifi-test/produkt/brinkmann-taurus-1785

The modern Brinkmann DDs ( I lump them together as they all have the same motor and bearing and control system) measure very well for w&f and rumble…for example.

I would like to see some data that belt drives have lower w&f numbers than modern or vintage DDs. Especially with needle drag I woukd be quite surprised if this were true. The best vintage DDs also had very low noise and rumble figures.According to my experience and turntables that I measured, direct drive's wow&flutter performance isn't better than belt drive. Basic and very cheap direct drives can be very good up to a certain point but after that even high end direct drives can not improve w&f figures much further. Another strange thing that some modern direct drives offer worse performance than old, vintage ones. The best w&f results can be achieved with top belt drives according to my experience. I haven’t measure modern idlers but old ones are not far behind of direct drives.

Belt drive’s problem is belt, direct drive and idler’s problem is not being able to separate motor from the plinth (there are some exceptions like Esoteric T1). Direct drive motors have another disadvantage like turning at platter speed (33.3rpm). Idler's disadvantage is noise because of idler mechanism.

IMHO/IME there are more important factors than drive type which makes a turntable sound good or bad. One of those factors is high mass platter. A high mass platter (preferably over 20kg) is the key factor for a good sounding turntable and helps solving problems introduced by drive type (BD, DD or idler). I believe implementation and how good a turntable is built is more important than drive type.

Keeping steady speed at 33.3rpm and w&f performance are two different things. Another very important problem for all drive types is aggressively trying to keep 33.3rpm speed by control electronics. That aggressive control may achieve 33.3rpm average but for the cost of increased w&f. Piano and violin sounds are very sensitive to w&f. It's a good idea to check how piano and violin sound when evaluating a turntable.

The modern Brinkmann DDs ( I lump them together as they all have the same motor and bearing and control system) measure very well for w&f and rumble…for example.

I have no knowledge or opinion on this, but I think J.R. Boisclair's view is that speed consistency (staying constant at whatever speed it is spinning at (say 33.38) is more important than whether the speed is exactly at 33.333.

Alternative if you need a good one.dcx 22l from maxonSorry, I meant Tech DAS in the AFO but does not reflect on Tech DAS for the reason stated below. I was merely referring to the beautiful motor they use They, and several others use the biggest motor from Pabst. These are superb, but as built had a fatal flaw. Used by the hundreds in old professional machines I mentioned they all fail. The reason for this is that the enamel used on the coil wire as insulation in the motor coils tends to crack with time and fall off in pieces. The result is a mortal short. Most modern builders get around this by totally rebuilding the motor before use. Karmelli I think does as does TechDas. Both are way too professional not to do so. One may however come across a homebuilt or lesser brand that does not do so and like me, then sit with a boxful of beautiful bricks.

I have no knowledge or opinion on this, but I think J.R. Boisclair's view is that speed consistency (staying constant at whatever speed it is spinning at (say 33.38) is more important than whether the speed is exactly at 33.333.

I think consistency is more important than accuracy as long as accuracy is within some narrow range of 33.33. I don’t know what that range is to be audible for pitch. Shouldn’t the best turntables be great at both?

How many people check the speed of the turntables? Admittedly, Wow and flutter is difficult to measure easily. I learned a lot by watching a Sutherland Timeline on various turntables. Shouldn’t expensive turntables purporting to be good have some kind of speed display?

0.1% is permitted for studio and broadcast devices and 0.2% for home devices. Higher speed fluctuations can be heard with sine tones. Source German hifi standard(book)I think consistency is more important than accuracy as long as accuracy is within some narrow range of 33.33. I don’t know what that range is to be audible for pitch. Shouldn’t the best turntables be great at both?

How many people check the speed of the turntables? Admittedly, Wow and flutter is difficult to measure easily. I learned a lot by watching a Sutherland Timeline on various turntables. Shouldn’t expensive turntables purporting to be good have some kind of speed display?

That's right and also that's what I tried to explain. You don't notice a difference if it runs a little bit slower or faster but you certainly notice when control circuit aggressively tries to fix every time it goes out of 33.33rpm.I have no knowledge or opinion on this, but I think J.R. Boisclair's view is that speed consistency (staying constant at whatever speed it is spinning at (say 33.38) is more important than whether the speed is exactly at 33.333.

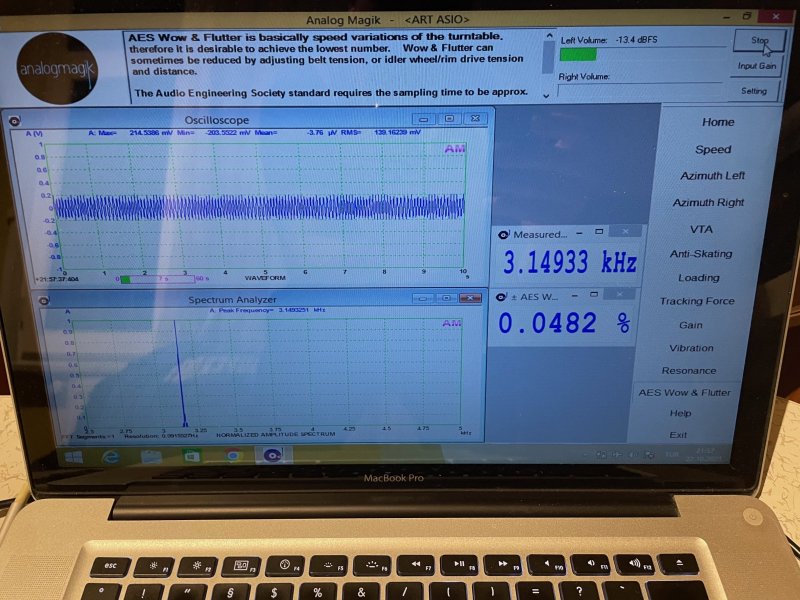

I don't know where but I shared comparison about this somewhere on this forum which includes numbers. Here is a La Platine Verdier belt drive w&f result in AES by AM software. TechDas AF1 premium was the same or %0.045 as far as I remember.I would like to see some data that belt drives have lower w&f numbers than modern or vintage DDs. Especially with needle drag I woukd be quite surprised if this were true. The best vintage DDs also had very low noise and rumble figures.

Here is my friend's Exclusive P3. It is a very good direct drive and it's in immaculate condition. I don't remember the actual result but it was something like %0.06. Unfortunately new Technics 1200G (not 1200GR or other lower model) couldn't manage to match P3's w&f performance, worse than that.

IMHO in terms of w&f tests AES takes longer and more reliable. It offers the best resolution IMHO. If you happen to use an alternative w&f measurement like ShaknSpin you'll most likely get a better result because of low resolution or looser standard. I would like to see AM software w&f results members have to generate a database.

BTW the worst w&f results I have ever seen also belong to belt drives, mostly cheap ones with poor motor and light platter. Belt drive can perform very bad if not done properly.

Last edited:

yes. steady is job one. and better than more accurate but shaky on a micro level.I have no knowledge or opinion on this, but I think J.R. Boisclair's view is that speed consistency (staying constant at whatever speed it is spinning at (say 33.38) is more important than whether the speed is exactly at 33.333.

but both steady and accurate being right on is ideal.

… not asking for a definitiv answer or recommendation - but from your experience, what is the best for steady speed and at what price do TTs really perform to a satisfying level… it can’t be all about speed consistency, as i would assume, even lower priced TTs can do well (I measured some around 2-3k and performance was flawless speedwise). My Brinkmann on the other hand measures terrible considering it‘s price, still it sounds way better to me than other TTs that measure better in w&f… really can‘t figure out how to go about this… I do have a spending frame between say 7k lowest (Stabi R that would probably be) and 40k (TechDAS AF 3 etc.)… but it can’t all be about just playing at steady speed, because that’s affordable at a much lower invest… then again - as said - there are TTs that don’t measure well at all but sound great… weird stuff…yes. steady is job one. and better than more accurate but shaky on a micro level.

but both steady and accurate being right on is ideal.

Similar threads

- Replies

- 13

- Views

- 5K

- Replies

- 41

- Views

- 23K

- Replies

- 168

- Views

- 56K

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |