Neil: thanks. I'd seen it but it's been awhile. Reviewing it, my initial concerns remain. Now if one were to load up a section of a metal master, now that might address whether some detail is obscured by the conductive coating that has to be placed on the record. At this point at this magnification all I'm sure of is if there are large bits, they will be revealed. Not sure how one goes about doing valid before/after though. Once you've put your conductive coating on the record, any means of removing it likely removes some contamination. What are your thoughts? Is there all that much to be gleaned from such imagery?Jim:

This video of how a stylus in a groove video was produced should answer all your questions -

Degritter Mark II

- Thread starter tima

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jim, thanks for your video. The best I have seen on the Degritter operating. The watt meter suggests that the unit is drawing rated power (~300W) for the UT, noting that the power supply would not be 100% efficient and that there would other power to the spinner, pump and electronics.Morning Neil. Now, here's a link to the most boring video ever. This is the static shot of the Degritter MKII I used to time the cycles. I put a watt meter in line, so at one point I bring that into view. - Jim

Jim, @tima will correct me if I am wrong, but he is not cleaning used records of dubious condition. Also, consider that he is using Tergitol 15-S-9 at 150-ppm which is gives both wetting and detergency, and he is adding 2.5% IPA and this can assist with the how well the Tergitol works. The Degritter because of its pump system cannot use any surfactant at that kind of concentration; otherwise, it will foam too much causing all kinds of problems such as the level sensors and the pump. The benefits of some detergency combined with ultrasonics significantly improves the overall cleaning efficiency. You really cannot compare the Degritter with what Tim is doing. The Degritter is a high performance, ultrasonic record cleaning system that tradeoffs performance for compact size, convenience and cost. But Tim's system is a high performance filtered ultrasonic cleaning system configured for record cleaning. The titles are somewhat subtle, but the equipment differences are significant as is the performance opportunities.It sounds like @tima is getting similar, or perhaps superior results to me without (I think?) all the pre-cleaning, with less total ultrasonic contact time

Jim, this adds a lot of time to your process. It adds 40-min/record (20-min/side). The general recommendation for an enzyme soak for clothing is about 15-min with some variation depending on enzyme and soil. But for record cleaning AIVS only recommends not more than 5-min - Directions for Use (audiointelligent.com) for this simple reason "Although the fluid quantity is sufficient to cover the surface of the record, the quantity of fluid is small. As contaminants break down, they can populate the fluid to the point of obstructing the effectiveness of the enzymatic content...If this happens, the used fluid needs to be removed from the record and new fluid applied."(6) A fresh application of Down With Dirty is applied, covering the record. Fluid is agitated, creating a small amount of foam. The VPI lid is then placed over the disc to reduce evaporation and keep it wet as it soaks for 20 minutes.

(7) After 20 minutes, the DD brush is held steady as the record rotates in both directions. If the remaining fluid isn’t sufficient to create a good head in front of the brush, additional cleaning solution is applied. After several rotations in both directions, the fluid is vacuumed off.

You may be better off just doing two 5-min soaks; and cut 10-min out of your process. Also, for your steps (4) and (5), you want to consider Liquinox at 0.5% then follow with AIVS enyzme. This way you get the best of all worlds. The Liquinox which will wet on contact does the initial heavy lifting. The follow with enzyme and then follow with Tergitol at 0.025% for the final cleanup of any ionic residue. So, your process would look like this:

(1) Lightly sprayed OA brush is used during initial inspection on free spinning turntable to remove most surface debris.

(2) Lightly sprayed white Zeiss microfiber brush is then used to remove more surface debris.

(3) Disc is inspected. Any visible hard bits are removed.

(4) Disc is placed on VPI and dry vacuumed for one rotation.

(4) DD brush is used to spread a layer of 0.5% Liquinoix and then vacuumed off.

(5) DD brush is used to spread 0.5% Liquinoix. Sufficient fluid is applied to create head in front of brush. Brush is held steady for one rotation, then platter is reversed and brushed again. Fluid is agitated, creating a large amount of foam. Fluid is then vacuumed off.

(6) DD brush is then used to spread DW. The brush is lightly agitated as the turntable rotates in both directions. Sufficient fluid is applied to assure a head is created in front of the brush. The fluid is then vacuumed off.

(7) DD brush is used to apply Down With Dirty, covering the record. Brush is held steady for one rotation, then platter is reversed with brush held steady to get uniform coating. Fluid is then agitated, creating a small amount of foam. The fluid then soaks for 5 minutes, is then lightly agitated and is then vacuumed off.

(8) If record was very dirty to start - Repeat Step (7), otherwise proceed to Step (10).

(9) Repeat Step (6).

(10) DD brush is used to spread 0.025% Tergitol. Sufficient fluid is applied to create head in front of brush. Brush is held steady for one rotation, then platter is reversed with brush is held steady. Fluid is then agitated, creating a small amount of foam. Fluid is then vacuumed off.

(11) Repeat Step (6)

(12) The VPI clear wand assembly is replaced with the DIW rinse only Delrin wand assembly and Step (6) repeated.

Keep im-mind, for you, the goal is not just good enough but best achievable.

Hope this is of some help.

Neil

Jim, yes, use of an electron microscope is not an actual picture of the record surface but an of an applied electron reflective layer. However, the Olympus high magnification digital microscope 'should' be a better representation of the actual surface.Neil: thanks. I'd seen it but it's been awhile. Reviewing it, my initial concerns remain. Now if one were to load up a section of a metal master, now that might address whether some detail is obscured by the conductive coating that has to be placed on the record. At this point at this magnification all I'm sure of is if there are large bits, they will be revealed. Not sure how one goes about doing valid before/after though. Once you've put your conductive coating on the record, any means of removing it likely removes some contamination. What are your thoughts? Is there all that much to be gleaned from such imagery?

Morning Neil: Here's another link for you. These photos were taken during one of my vinegar rinses. The microfiber cloth shows what IPA removed from the splash guards. The filthy drops on the top of the tank sides are also the results of using IPA on a cotton swab.Jim, thanks for your video. The best I have seen on the Degritter operating. The watt meter suggests that the unit is drawing rated power (~300W) for the UT, noting that the power supply would not be 100% efficient and that there would other power to the spinner, pump and electronics.

The white etching you see is not significant enough to be felt with a finger, but I suspect it may be the result of the AIVS fluid, as no one else has reported it to my knowledge.

The dual water line is the result of having used two of the three water height options. Degritter recommends using the highest water level when cleaning the tank. In my experience nothing short of manual cleaning will remove those "bathtub rings."

Also note the debris clinging to the top of the splash guards. The guards are a fairly dense, but porous material. Pressing on them when dry, then pressing again when wet will release air, so assume they're taking on spent fluid and I take that into account when cleaning.

I believe that sort of debris on the guards may be the source of small fluid drops ending up on the label, but it's only a suspicion. Regardless, during cleaning the top of the tank and these guards get a lot of attention. I'm now using an old sonic toothbrush on those areas.The overall results of this cleaning

https://www.icloud.com/sharedalbum/#B0e5kuVsbzE1fj

As for the watt meter, I initially used it shortly after I got the Degritter MKII, because I noted a significant difference in dB and the characteristics of the sound when it was cold vs. warm. I wanted to confirm the transducers were all firing (they were). The watt meter refreshes a little too slowly for my taste, but what I can tell you is that power consumption does vary, presumably due to the sweep function, but also depending on bath temp. It can read far higher than spec. when cold and I have experienced one time when power consumption was so low and bath temp so warm I thought they might have put in a power ramp down routine to protect the machine. I haven't been able to confirm that. What I can confirm is if you throw it into degas mode, any power management function is turned off and the reading is very much in line with the published power consumption. I also captured numbers for total power consumption during soaks, which gives you everything but the transducers.

I agree with most of what you said in this section, but question just the first part of this one line. My opinion is that the Degritter is underpowered and as you said that's the tradeoff. They simply weren't able to come up with a heat dissipation routine adequate to allow for much longer run times. The other tradeoff, which you know of course, is the filtration system. I suspect it does more to protect the pump and valves from getting impacted by very large debris than it does to filter the water. For me, the biggest benefit in the design is that it's allowed me to hear for myself the changes in playback that come after each four rotation cycle. Peeling back the onion, I suppose.The Degritter is a high performance, ultrasonic record cleaning system that tradeoffs performance for compact size, convenience and cost.

Neil, boy howdy, yes it does! I hadn't read Jim Pendleton's directions for some time, so thanks for that. Nevertheless, as my intent is to shorten and simplify the process, not the other way around, yesterday morning I processed one side of one disc with the soak, the other without. The disc was auditioned prior to and after the VPI cleaning. I did not hear any difference. It may be there was some change, but generally if a variation in my method doesn't result in a change that jumps out at me, I just dump it. Both sides of that disc did improve after every 4-rotation cycle, but once again, it was still getting better after six runs. Most are fine at four, but if that bottom hasn't appeared at that point I'll do another two rounds and more times than not, the extra contact time does the trick.Jim, this adds a lot of time to your process. It adds 40-min/record (20-min/side). The general recommendation for an enzyme soak for clothing is about 15-min with some variation depending on enzyme and soil. But for record cleaning AIVS only recommends not more than 5-min - Directions for Use (audiointelligent.com) for this simple reason "Although the fluid quantity is sufficient to cover the surface of the record, the quantity of fluid is small. As contaminants break down, they can populate the fluid to the point of obstructing the effectiveness of the enzymatic content...If this happens, the used fluid needs to be removed from the record and new fluid applied."

Thanks Neil. I hadn't thought of placing an AIVS enzyme run between Liquinox and Tergitol. More steps, which I don't care for, but as you say, if I'm not prolonging contact time for each step, not that big a deal. I've copied your mods to my process and will give it a try.You may be better off just doing two 5-min soaks; and cut 10-min out of your process. Also, for your steps (4) and (5), you want to consider Liquinox at 0.5% then follow with AIVS enyzme. This way you get the best of all worlds. The Liquinox which will wet on contact does the initial heavy lifting. The follow with enzyme and then follow with Tergitol at 0.025% for the final cleanup of any ionic residue

ALARA. "reasonable" always being up for debate. Ah, memories of the bad ol' days . . . BTW Neil, as I mentioned peeling back the onion, how what I hear being addressed by the Degritter first are the high frequencies, the lows last (it's a little more complicated than that, honestly), I do wonder if when people are doing listening tests and trying to determine the effectiveness of their cleaning process, whether there's more to be achieved, if there isn't too much emphasis on the high end, not enough attention given to the bottom.Keep im-mind, for you, the goal is not just good enough but best achievable.

I also wonder if the reason for the "order of appearance" of different frequency bands as it were has something to do with basic numbers, i.e. the characteristics of the groove that reproduce high frequencies are of a smaller shape and size, thus if the same amount of material is removed from them as much larger elements that make up the lower frequencies, those smaller elements are being physically changed to a larger degree than the bigger ones.

I wonder if that, coupled with something you said about the higher frequency elements of the groove being at the top of the groove wall doesn't explain my experience - that it is much easier to restore (or veil) the highs than it is the lows. Also why it takes more passes before the highs sound "right," more passes before the mix becomes balanced, etc.

Now, it may be that what @tima is achieving thanks to the lower frequency ultrasonics doesn't cause this stepped revealing of frequencies and if so, I'm all for it. Sorry to go on about it, but more and more I pay less attention to what I hear first, more and more to what just doesn't get addressed without a great deal more effort.

Jim:My opinion is that the Degritter is underpowered

The Degritter is not underpowered. Please recall what I said in this post WRT rules for ultrasonics https://www.whatsbestforum.com/threads/ultrasonic-cavitation-cleaning-explained.36690/post-870704 and specifically -The cavitation intensity is proportional to the bubble diameter and the tank power (watts/L) but there is a maximum power above which no addition cavitation intensity is obtained. The fundamental problem you are experiencing with Degritter is simply that the high frequency while producing a smaller bubble and more of them, produces a lower cavitation intensity (compared to 35-40-kHz).

Consider this very simplified sand-paper analogy. The 120-kHz is like 400-grit while the 35-40-kHz is like 240-grit. If you are trying to remove thick detritus with 400-grit, its going take a lot of sandpaper. The 240-grit will cut through it quickly and as long you do not use too much pressure/speed (i.e. power & cavitation intensity) you will not damage the surface. But to get that final finish, 400-grit is what you want. So, if cleaning dirty records, to get the most efficient process with the Degritter you want a very aggressive and effective pre-clean step(s) otherwise, you are going to be doing multiple cleaning cycles with the Degritter. @tima Elmasonic P-series UT, with both 37 & 80 kHz provides the best of both worlds but for gross detritus of a flea-market record, you want to preclean to prevent excessive UT tank bath refresh.

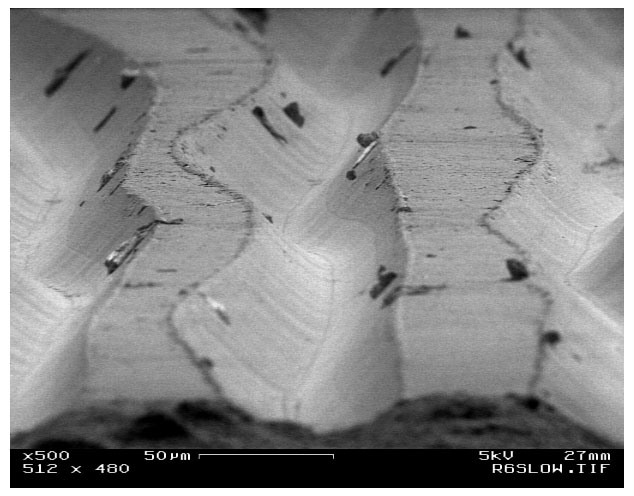

Jim: Look at this photo of a record groove and pay attention to the scale. The high frequencies are produced by the close space side wall grooves - and it has nothing to do with top or bottom. The distance between the ridges produces the frequency. The height of the ridge produces the output (dB). A dirty groove is going to pack in detritus in the valley which can reduce the output (dB); ergo cleaning can improve the high frequency output, but the opposite is the veiling of high frequencies that is often attributed to cleaner residue which is viscous can pack into the valley.I also wonder if the reason for the "order of appearance" of different frequency bands as it were has something to do with basic numbers, i.e. the characteristics of the groove that reproduce high frequencies are of a smaller shape and size, thus if the same amount of material is removed from them as much larger elements that make up the lower frequencies, those smaller elements are being physically changed to a larger degree than the bigger ones.

I wonder if that, coupled with something you said about the higher frequency elements of the groove being at the top of the groove wall doesn't explain my experience - that it is much easier to restore (or veil) the highs than it is the lows. Also why it takes more passes before the highs sound "right," more passes before the mix becomes balanced, etc.

The fly in ointment is people's individual hear ability. Peoples hearing ability differs; no different than any other human attribute; not everyone is 'gifted' with exceptional cardiovascular capacity to achieve Olympian (or paid) status be it cycling, swimming, running, etc. Recall what the book says: XI.7.3 There are audio enthusiasts with very high-resolution systems in acoustically engineered rooms that can reveal details not otherwise achievable. For these individuals, the best achievable cleanliness level may yield acoustic benefits. Some people have very sensitive hearing and likewise can benefit from the best achievable cleanliness level. Consider what is written page 16 – of UIUC Physics 406 Acoustical Physics of Music ©Professor Steven Errede, Department of Physics, University of Illinois at Urbana-Champaign, Illinois 2002 - 2017. The Human Ear ⎯ Hearing, Sound Intensity and Loudness Levels (78) "The time averaged, or RMS sound intensity threshold of hearing (@ f = 1 KHz) is: ~ 2.5x10-12 RMS Watts/m^2 = 2.5 RMS pico-Watts/m^2. Individual people may hear better/worse than the average person, and so threshold of hearing from one person to another can vary as much as 1/10 or 10X this!!!".

So maybe you are gifted (or cursed) with exceptional high frequency sensitivity; it's your journey. With my multi-step/multi-chemical sink-manual clean process that I use for record cleaning, multiple cleanings (completing the total process multiple times) provide me no detriment or improvement of high frequency information and I have four different cartridges at my disposal with two always in use on a dual arm table and a fairly high-resolution system - see my profile at SH Forums @pacvr. I do repeat cleaning to remove tightly adherent particles that may not be removed during the first cleaning. But the 2nd cleaning only uses Citranox and Tergitol. The 'inconvenience' is inconsequential to me, and I do not clean enough records to warrant a more automated process.

But the multi-step/multi-chemical sink-manual clean process is technique dependent. Its like the book says: XII.16 The final chapters of this book will discuss machine assisted cleaning methods: vacuum record cleaning machines (RCM) and ultrasonic cleaning machines (UCM). It’s important to consider that machines are generally developed for two primary reasons – reduce labor and improve process efficiency. Process efficiency can mean faster (higher throughput) and/or higher probability of achieving quality or achieving a quality that manual labor cannot produce. Manual cleaning in the appropriate environment with appropriate controls can achieve impressive levels of cleanliness, but the labor, skill, time and probability of success generally make it impractical for manufacturing environments. But for the home audio enthusiast, depending on your attention to details, adopting machine assisted cleaning may or may not yield a cleaner record. However, the ease of use and convenience provided by machines can be very enticing and cannot be denied.

Take care,

Neil

Afternoon Neil. Reading through your response, I'd say I used the wrong word, because I at least have enough of a grasp of the differences you address via the sandpaper analogy, to know I should have taken more care. I should have said the Degritter's ability to dissipate the heat generated by its transducers is a major limitation. The designers seem to have to set time limits for cycle duration based on that limitation, not based on what's necessary to achieve optimal results. So yes, it's not "underpowered." It's designed for a demographic I'm not part of.The Degritter is not underpowered.

Thanks Neil. So I'm incorrect in recalling you'd once responded to a post with a reference to the higher frequencies being at the top of the groove? I'm not doubting the photo or what you say here, just trying to reconcile why I thought you'd said that.Jim: Look at this photo of a record groove and pay attention to the scale. The high frequencies are produced by the close space side wall grooves - and it has nothing to do with top or bottom. The distance between the ridges produces the frequency. The height of the ridge produces the output (dB). A dirty groove is going to pack in detritus in the valley which can reduce the output (dB); ergo cleaning can improve the high frequency output, but the opposite is the veiling of high frequencies that is often attributed to cleaner residue which is viscous can pack into the valley.

With respect to what the photo shows and what you say, I'd just add this. If we look at the relationship of hill to valley, then as the valley is filled doesn't the slope change?. If material at the peak and high top of that hill is removed first, doesn't the slope change? If material is removed from one side of the hill but not the other, doesn't the slope become unequal? If material is unequally removed from a peak, making it ragged, doesn't that matter? Don't these changes in slope and smoothness also alter sound reproduction? If the valley between high frequency peaks is smaller than it is for lower frequencies, if a cleaning method is able to remove the same amount of material from all surfaces, wouldn't the smaller high frequency valleys have more material removed from them in relation to their size?

I am gifted and cursed in so many ways . . . but with respect to my high frequency hearing, it's my understanding that not everyone can hear the oscillators used in cathode ray tube TVs. I can, and I can hear them if I'm in the next room. Having worked in TV control rooms in the 70's I kind of got used to it. When we went all flat screen, it was like the life was taken out of the room. But I do hear above whatever freqency that is, and unfortunately that includes a persistent ringing that I'm glad is very low level and easily drowned out.Consider what is written page 16 – of UIUC Physics 406 Acoustical Physics of Music ©Professor Steven Errede, Department of Physics, University of Illinois at Urbana-Champaign, Illinois 2002 - 2017. The Human Ear ⎯ Hearing, Sound Intensity and Loudness Levels (78) "The time averaged, or RMS sound intensity threshold of hearing (@ f = 1 KHz) is: ~ 2.5x10-12 RMS Watts/m^2 = 2.5 RMS pico-Watts/m^2. Individual people may hear better/worse than the average person, and so threshold of hearing from one person to another can vary as much as 1/10 or 10X this!!!".

So maybe you are gifted (or cursed) with exceptional high frequency sensitivity; it's your journey.

But the changes I hear as I go though what can only be called a, b, c, d, e, f comparisons when cleaning go well beyond coarse amplitude changes, though that's clearly part of it, a big part of why once a record is as clean as I'm able to get it, the mix sounds much more right. It may not be exactly what the mastering engineer intended, but a darned site closer than when I start.

I'll give you an example: Carlos Santa, John McLaughlin - A Love Supreme from the Love, Devotion, Surrender album. Do you know it? It starts with a guitar riff, but there's a bass line that ties everything together and it continues throughout the track.

After the pre-cleaning, which I did based on your last recommendation, I didn't even hear the bass line until after the initial guitar riff. When I did hear it, I knew it wasn't supposed to be that far under, that it was supposed to be right up there, giving weight, strength, creating the total feel for the track. One Heavy cycle in the Degritter brought it up, but still not where I was sure it was supposed to be. Two more Heavy cycles and now we're in business. Now many other aspects of the track altered with each step - additional clarity, channel separation, guitars fleshed out, timbre appeared - the general feeling that there's a hole in the mids faded away. What started out as a thin, rather shrill sounding track began to sound right, became engaging on an emotional level. Now, it's not quite there yet, but letting it run through two more Heavy cycles is probably gonna do it for this one.

There's something else at play here. My sound system. I totally understand the much, much better systems than mine are far more resolving, but it just may be that when it comes to hearing the kinds of differences I do, that I'm hindered or helped depending on how you look at it, by a system that certainly doesn't have power to spare, hardly is a bass beast (I mean, look at my phono stage and amp). The changes I hear may be quite evident here, not just because of my ears, but because my sound system just won't wake up and reproduce certain frequencies until they get to a certain amplitude, whereas yours would play the same track much, much better initially. Shorter version: You've got everything necessary to get the most out of a recording with room to spare. I don't.

Yes, absolutely it is. I have no doubt if I were to put together a 30-minute video with closeups of every step in my process and you were to be good enough to critique it, there would be changes that might improve my results. But I have changed my process multiple times since I got the Degritter and again, no change or combination of changes has altered the difference between what I hear after manual cleaning and a single Heavy cycle in the Degritter, even without rinsing before the audition.But the multi-step/multi-chemical sink-manual clean process is technique dependent.

More time brushing? I've done it. Different brushes? I've done it. Hold the brush differently, press harder or lighter? I've done it. Agitate in shorter strokes, longer strokes, for more rotations? I've done it. Change fluids, cleaning concentrate amounts, multiple applications of the same fluid? I've done it. Double, triple, quadruple rinse (not kidding) I've done it. Rinse every brush after every use, first under hot running water, then agitated in the sink, drained the sink, agitaged again, then sprayed down the brush on both sides and the bottom of the bristle pack with copious amounts of distilled water and then using an inverted wand on the VPI, sucked most of the water out? I always do that now. Dedicate brushes to each step? I've done that, too. Make certain the record never is allowed to dry between steps? I do that, too. It just never results in a post pre-cleaning audition that touches what one Heavy cycle in the Degritter does. But I say all that and I remember while that's a goal I'd like to reach, the primary goal, which I believe I've already achieved, is to remove as much material as I can before I use the Degritter, because keeping that machine clean is paramount and no easy task as it is.

Jim:Don't these changes in slope and smoothness also alter sound reproduction? If the valley between high frequency peaks is smaller than it is for lower frequencies, if a cleaning method is able to remove the same amount of material from all surfaces, wouldn't the smaller high frequency valleys have more material removed from them in relation to their size?

1. If you look at Figure 43 of the book, the wavelength (peak to peak distance) of the lower frequencies <200 Hz are measured in millimeters. The long grooves are easy to clean. The more difficult grooves to clean are the high frequency grooves. The book in XII.3 briefly summarizes work that was done >25-yrs ago but what is not addressed is how testing was done. We had a fluid test loop with clear sections of pipe and had Tees where threaded rods were inserted loaded with soil that we could remove and weight pre-post. For optimum cleaning performance, flushing forwards and backwards is required for systems that had any irregular geometries. Fluid motion past a sharp irregularity would mostly bypass the backward side.

2. If you look at the various graphs at this site On The Record (audiomisc.co.uk) you will see the groove velocity and acceleration for some music. The book XI.4.2 The stylus as it moves laterally and vertically is displaced, and displacement over time equals velocity and from velocity comes acceleration and all of this is combined to be the modulation amplitude – the stylus motion that produces an audible signal. The equation for acceleration shows it proportional to the amplitude x frequency squared. So, the high accelerations are associated with high frequencies and recall that the RIAA equalization cutting curve attenuates the everything <1-kHz and amplifies everything >1-kz (everything is reversed on playback). When you consider the very high g-forces the stylus imparts at the high frequencies, it becomes extremely unlikely that a soft-viscous residue can alter the shape/height of the peak with any reasonable amount of cleaner residue.

3. The book in XI.2.6 The NVR nominal film thickness (Contamination Control Engineering Design Guidelines for the Aerospace Community, NASA Contractor Report 4740, May 1996) (55) shown in Table XV assumes the contaminant is uniformly applied and has a density of 1-g/cm³ = 62.43 lbs/ft³ (same as freshwater); and while a 1-micron film calculates to about 9.1 mg/ft², for ease of use 10 mg/ft² equals 1-micron thickness is applied. The book Table XVII Record Groove Velocity vs Frequency & Amplitude, shows a 9.5-dB signal at 5-kHz to be 0.955 microns. In order to affect a significant increase (+2.5-dB) in the signal to 12-dB, the amplitude would need to increase to 1.273-microns or +0.318-micron which would be equal to a uniform later of residue = 3.18-mg/ft^2 which is grossly dirty. The target goal to mostly eliminate influence of residue from playback based on all user experience (except yours) is <0.03-micron thickness or< 0.3-mg/ft^2 which by Table XVIII Residue Thickness from Cleaner Residue, that would mean not rinsing at all the Tergitol final clean and leaving 2-3-ml/side to dry.

4. In Dec-22, I worked with someone in the UK is testing the rinse cycle of vacuum-RCM (a Nessie was used). Liquinox was spiked with a very powerful UV fluorescent dye that would be visible in fractions of a ppm (parts per billion). Upon vacuum of the Liquinox the record surface showed no fluorescence. When rinse water was applied, the fluorescence appeared. It took two full rinses to remove evidence of fluorescence, ergo evidence of Liquinox. The moral of the story is that vacuum-RCM (blower style) does not suck up all fluid, some is dried in-place. Rinsing is very important. Your current pre-clean process with the final clean with Tergitol at 0.025% (= 250-mg/L) follows the double final rinse. Therefore, the probability of cleaner residue from your pre-clean process should be very remote.

There is an interesting take-away from what you say. The pre-clean process is repeatable in that it achieves the same results every time - shrill highs and reticent bass. When you are cleaning with the Degritter following pre-clean, you make no mention of any unusual increase in TDS which would indicate carryover of anything ionic. TDS will naturally increase just based on exposure to air with its (high these days) CO2 that is absorbed forming carbonic acid - I left a glass of DIW out on a counter uncovered and TDS increased about 0.2-0.3-ppm/day. You make no mention of unusual foaming which would be a sign of Liquinox or nonionic Tergitol carryover. At this point, I can only conclude it may be associated with your exceptional high frequency sensitivity. From this writeup Cathode-ray tube - Wikipedia it appears that CRT oscillation would occur at 15-kHz and above. If you are extremely sensitive to high frequencies, it could overload your audio perception of the music (hearing is a psychoacoustic process) pushing the bass back. In your case, the Degritter is essentially "conditioning" the record. Exactly what that means - TBD, but you have a process and it works for you. And, I always say, the best cleaning process is the one that is best for you.But I have changed my process multiple times since I got the Degritter and again, no change or combination of changes has altered the difference between what I hear after manual cleaning and a single Heavy cycle in the Degritter, even without rinsing before the audition.

Take care,

Neil

This is about Degritter and I have a Kirmuss. But its also about what constitutes clean. So, I used the Kirmuss process a few times over a valuable old record. It did not get rid of noise and loss of frequency . I then used my hand clean and heard no change.

Yes, Mark's told me about how you assisted him with that experiment.4. In Dec-22, I worked with someone in the UK is testing the rinse cycle of vacuum-RCM (a Nessie was used). Liquinox was spiked with a very powerful UV fluorescent dye that would be visible in fractions of a ppm (parts per billion). Upon vacuum of the Liquinox the record surface showed no fluorescence. When rinse water was applied, the fluorescence appeared. It took two full rinses to remove evidence of fluorescence, ergo evidence of Liquinox. The moral of the story is that vacuum-RCM (blower style) does not suck up all fluid, some is dried in-place. Rinsing is very important. Your current pre-clean process with the final clean with Tergitol at 0.025% (= 250-mg/L) follows the double final rinse. Therefore, the probability of cleaner residue from your pre-clean process should be very remote.

I wouldn't characterize the sound after pre-cleaning quite that way, but yes. The highs present themselves pretty well, but they're not fleshed out. The lows are certainly as you describe.There is an interesting take-away from what you say. The pre-clean process is repeatable in that it achieves the same results every time - shrill highs and reticent bass.

I'd say that's a hole in my narrative, much like the mids after pre-cleaning, but easily filled! Regardless of pre-cleaning, I normally see a slightly greater increase in TDS for the first cycle on a pre-cleaned disc, but anything over 0.3 ppm for that first cycle would be unusual. I also routinely see a slightly higher TDS for the first cleaning cycle of a fresh tank, also again nothing over 0.3 ppm.When you are cleaning with the Degritter following pre-clean, you make no mention of any unusual increase in TDS which would indicate carryover of anything ionic.

I did for quite some time record TDS after each cycle, giving the meter anywhere from :60 to 2:00 to settle down, the longer periods if the tank temp had risen above 86 f. While there have always been those discs that release more after an ultrasonic cleaning cycle, in recent months the TDS rise per 4 rotation Heavy cycle is commonly 0.1 ppm. Lid on the tank overnight and a measurment the next morning may show a 0.1 ppm rise, but often it does not. 0.0 ppm rises per cycle do occur, but are rare, but when they do occur, I can't say I can equate them with no sonic improvement.

And thanks Neil for the sources you provide. I'll go through them as I have time. Some health issues slowing me down this past week. Maybe heart, maybe my old anxiety banging on my heart. Continuous heart monitor just got shipped off yesterday after a week, so we'll see.

But just scanning these sources, I do wonder if we're not comparing apples to oranges when we jump from manual cleaning, including wet extraction, to ultrasonics. My impression remains that with respect to the Degritter, the 120 kHz ultrasonics address the whole matter of removing contamination from the groove so differently they breeze through what other methods struggle with - and vice-versa. My personal experience remains - that with the Degritter MKII, the highs see the most improvement first, the lows last. And that's one of the characteristics of this machine that, if it does not hold true for the lower frequency machines like @tima 's setup, would really prompt me to move in that direction.

Again, I don't think everything I'm hearing in terms of changes from cycle to cyle can be attributed to my having the ears of a bat. More likely it's that my sound system, being bass shy, not having the channel separation more sophisticated and powerful sytems do, and having no gain to spare (some discs are cut so quiet setting to my normal listening level doesn't leave more than a few clicks before the amp will clip) means that any change of a set magnitude simply is going to much more forcefully present itself to me.

For instance if If we characterized my system's bass response as a 2 and yours as a 10 and my cleaning process did nothing to increase gain in those frequencies until the third four rotation pass in the Degritter, but at that point it took it up 1, I'm pretty sure that would be far more audible to me than to you. In fact, when it comes to the bottom end, on many discs I can tell when the sub's cone starts moving. I not only can hear it. On occasion I've reached under, put a finger lightly on the surround after each cleaning and can feel when it's beginning to move. I know, not very scientific, but it's a check on my ears.

On the other hand, some change you might make to your system, which you might describe as "subtle, but beautiful," if my system could accept the component that affected that subtle change for you and not be hindered by other components in the chain? Well I might describe that as "OMG, that's the biggest change I've ever made to my system." - jim

Jim,Some health issues slowing me down this past week. Maybe heart, maybe my old anxiety banging on my heart. Continuous heart monitor just got shipped off yesterday after a week, so we'll see.

Sorry to hear about you being under the weather, best wishes for good news and a speedy recovery.

Take care,

Neil

Hey, @Neil.Antin, I think we chatted on the old vpiforum board a while back.

I've been using a variation of your cleaning solution recipes, dumbed down for me by another chemist in the community. I've been using a 10ml Liquinox per Liter distilled water dilution for my pre-cleaner, and 25ml/L Ilfotol for main cleaner, in rinsed out old AIVS dispenser bottles. Using Listener Select brushes and an older Okki Nokki, I've had largely good results with this, doing a 1 minute agitation of the Liquinox dilution, vacuum the brush and fluid, rinse agitation with lab grade water for about 30 seconds, then 1 minute agitation with Ilfotol dilution with a second brush, then rinse and agitate with that second brush. Do those proportions sound correct to you?

Of late, I've been getting frustrated that this isn't enough, thus my stumbling across this thread in my unrelenting lust for the Degritter. I'm still torn between crippling perfectionism and being discouraged by all the manual labor. Reading through this thread confirms my fear from other positive reviews and the opinion of that other chemist: The Degritter would be a useful ADDITIONAL tool, but wouldn't shorten the process, as nothing replaces the chemicals doing their job. That makes the expense near impossible for me to justify.

I do have an older DIY ultrasonic setup that I've tried experimenting with recently, but my experiments have been... mixed. My setup is a Sonix IV 60kHz ultrasonic machine, and a DIY motor setup with an extremely slow rotation (5 rotations per hour). During one attempt to use a tiny amount of Ilfotol in the tank to maybe help with reduce my need for scrubbing, I think some of the solution dried onto the grooves of one album, as the first half of each side now has a persistent high noise floor compared to previously. I'd let it run through this for 4 full rotations, so roughly an hour in the tank. I tried another manual scrubbing pass as detailed above to try to remove that noise, but that didn't seem to help. Can dried-on Ilfotol be removed somehow? Or is it more likely that using that made my ultrasonic tank cause actual damage to the record? I'd been under the impression that 60kHz was far more safe for vinyl than the normal 40kHz.

I've also tried using the AIVS Enzymatic Solution for Ultrasonic Cleaners, and at times it seems to be OK, at the very least helping reduce any static from all the vacuum passes. I'm just not sure if it's helping anything or not. I've ordered a faster rotisserie for further experiments, and in the hope of avoiding letting anything dry into the grooves.

I noticed you mentioned using the Down With Dirty enzymatic solution between the Liquinox pre-clean and Tergitol/Ilfotol final clean. Would the AIVS No 15 do as good a job there instead when fingerprints seem to not go away? Is there any real benefit in multiple passes of the Liquinox-then-Ilfotol process (rinsing in between and after each)? How the hell can I shorten this slog and reliably improve effective cleaning? Is there even any benefit to trying to use my ultrasonic as part of this whole process?

I've been using a variation of your cleaning solution recipes, dumbed down for me by another chemist in the community. I've been using a 10ml Liquinox per Liter distilled water dilution for my pre-cleaner, and 25ml/L Ilfotol for main cleaner, in rinsed out old AIVS dispenser bottles. Using Listener Select brushes and an older Okki Nokki, I've had largely good results with this, doing a 1 minute agitation of the Liquinox dilution, vacuum the brush and fluid, rinse agitation with lab grade water for about 30 seconds, then 1 minute agitation with Ilfotol dilution with a second brush, then rinse and agitate with that second brush. Do those proportions sound correct to you?

Of late, I've been getting frustrated that this isn't enough, thus my stumbling across this thread in my unrelenting lust for the Degritter. I'm still torn between crippling perfectionism and being discouraged by all the manual labor. Reading through this thread confirms my fear from other positive reviews and the opinion of that other chemist: The Degritter would be a useful ADDITIONAL tool, but wouldn't shorten the process, as nothing replaces the chemicals doing their job. That makes the expense near impossible for me to justify.

I do have an older DIY ultrasonic setup that I've tried experimenting with recently, but my experiments have been... mixed. My setup is a Sonix IV 60kHz ultrasonic machine, and a DIY motor setup with an extremely slow rotation (5 rotations per hour). During one attempt to use a tiny amount of Ilfotol in the tank to maybe help with reduce my need for scrubbing, I think some of the solution dried onto the grooves of one album, as the first half of each side now has a persistent high noise floor compared to previously. I'd let it run through this for 4 full rotations, so roughly an hour in the tank. I tried another manual scrubbing pass as detailed above to try to remove that noise, but that didn't seem to help. Can dried-on Ilfotol be removed somehow? Or is it more likely that using that made my ultrasonic tank cause actual damage to the record? I'd been under the impression that 60kHz was far more safe for vinyl than the normal 40kHz.

I've also tried using the AIVS Enzymatic Solution for Ultrasonic Cleaners, and at times it seems to be OK, at the very least helping reduce any static from all the vacuum passes. I'm just not sure if it's helping anything or not. I've ordered a faster rotisserie for further experiments, and in the hope of avoiding letting anything dry into the grooves.

I noticed you mentioned using the Down With Dirty enzymatic solution between the Liquinox pre-clean and Tergitol/Ilfotol final clean. Would the AIVS No 15 do as good a job there instead when fingerprints seem to not go away? Is there any real benefit in multiple passes of the Liquinox-then-Ilfotol process (rinsing in between and after each)? How the hell can I shorten this slog and reliably improve effective cleaning? Is there even any benefit to trying to use my ultrasonic as part of this whole process?

Since this post does not apply to the Degritter, I will be responding over at this thead: Ultrasonic Cavitation & Cleaning Explained | What's Best Audio and Video Forum. The Best High End Audio Forum on the planet! (whatsbestforum.com)Hey, @Neil.Antin, I think we chatted on the old vpiforum board a while back.

I've been using a variation of your cleaning solution recipes, dumbed down for me by another chemist in the community. I've been using a 10ml Liquinox per Liter distilled water dilution for my pre-cleaner, and 25ml/L Ilfotol for main cleaner, in rinsed out old AIVS dispenser bottles. Using Listener Select brushes and an older Okki Nokki, I've had largely good results with this, doing a 1 minute agitation of the Liquinox dilution, vacuum the brush and fluid, rinse agitation with lab grade water for about 30 seconds, then 1 minute agitation with Ilfotol dilution with a second brush, then rinse and agitate with that second brush. Do those proportions sound correct to you?

Of late, I've been getting frustrated that this isn't enough, thus my stumbling across this thread in my unrelenting lust for the Degritter. I'm still torn between crippling perfectionism and being discouraged by all the manual labor. Reading through this thread confirms my fear from other positive reviews and the opinion of that other chemist: The Degritter would be a useful ADDITIONAL tool, but wouldn't shorten the process, as nothing replaces the chemicals doing their job. That makes the expense near impossible for me to justify.

I do have an older DIY ultrasonic setup that I've tried experimenting with recently, but my experiments have been... mixed. My setup is a Sonix IV 60kHz ultrasonic machine, and a DIY motor setup with an extremely slow rotation (5 rotations per hour). During one attempt to use a tiny amount of Ilfotol in the tank to maybe help with reduce my need for scrubbing, I think some of the solution dried onto the grooves of one album, as the first half of each side now has a persistent high noise floor compared to previously. I'd let it run through this for 4 full rotations, so roughly an hour in the tank. I tried another manual scrubbing pass as detailed above to try to remove that noise, but that didn't seem to help. Can dried-on Ilfotol be removed somehow? Or is it more likely that using that made my ultrasonic tank cause actual damage to the record? I'd been under the impression that 60kHz was far more safe for vinyl than the normal 40kHz.

I've also tried using the AIVS Enzymatic Solution for Ultrasonic Cleaners, and at times it seems to be OK, at the very least helping reduce any static from all the vacuum passes. I'm just not sure if it's helping anything or not. I've ordered a faster rotisserie for further experiments, and in the hope of avoiding letting anything dry into the grooves.

I noticed you mentioned using the Down With Dirty enzymatic solution between the Liquinox pre-clean and Tergitol/Ilfotol final clean. Would the AIVS No 15 do as good a job there instead when fingerprints seem to not go away? Is there any real benefit in multiple passes of the Liquinox-then-Ilfotol process (rinsing in between and after each)? How the hell can I shorten this slog and reliably improve effective cleaning? Is there even any benefit to trying to use my ultrasonic as part of this whole process?

I just got my turntable back from service so I pulled the trigger on the Degritter Mark II.

I can’t stand using the SOTA anymore. It sounds like an industrial vacuum. I always wore earplugs when using it and I never cleaned many records as a result.

I’m looking forward to cleaning more records and doing it in a hands off manner.

Do I just get some distilled water and go to town? My reading says distilled water is cleaner than deionized water.

Thoughts?

I can’t stand using the SOTA anymore. It sounds like an industrial vacuum. I always wore earplugs when using it and I never cleaned many records as a result.

I’m looking forward to cleaning more records and doing it in a hands off manner.

Do I just get some distilled water and go to town? My reading says distilled water is cleaner than deionized water.

Thoughts?

Last edited:

I will be curious to know your results. From much of what I've been hearing and reading, it may be most effective as an additional tool rather than a replacement for chemicals and agitation on the vacuum RCM. I too am extremely weary of the tedium, and would love it if something like this could be a set-and-forget one-stop device.I just got my turntable back from service so I pulled the trigger on the Degritter Mark II.

I can’t stand using the VPI anymore. It sounds like an industrial vacuum. I always wore earplugs when using it and I never cleaned many records as a result.

I’m looking forward to cleaning more records and doing it in a hands off manner.

Do I just get some distilled water and go to town? My reading says distilled water is cleaner than deionized water.

Thoughts?

I will be curious to know your results. From much of what I've been hearing and reading, it may be most effective as an additional tool rather than a replacement for chemicals and agitation on the vacuum RCM. I too am extremely weary of the tedium, and would love it if something like this could be a set-and-forget one-stop device.

I’ll let you know. It has to be better than playing dirty records because I don’t want to listen to the SOTA anymore.

Last edited:

Do I just get some distilled water and go to town? My reading says distilled water is cleaner than deionized water.

Long story short, either is fine for record cleaning. If you are in the US, distilled water is readily available in your local grocery store. If you are in the EU/UK demineralized water is more readily available.

There are subtle differences between them, the pH of distilled water tends to be slightly above pH-7, while the pH of demineralized water tends to be less than pH-7. For the purposes of record cleaning, either is acceptable. As far as one being cleaner than the other. Distilled water is produced by boiling water and condensing the vapor. Demineralized water is generally produced in two steps, first fresh water is processed by reverse osmosis (RO) then passed through a demineralizer (mixed bed ion exchange resin). Both methods will remove all biologics and most ionic impurities. Laboratory grade ultra-pure water is either triple-distilled or passed through multiple demineralizer beds but is overkill for cleaning records.

You can easily check the purity of distilled or demineralized water with a total dissolved solids (TDS) meter. This unit is accurate at the very low levels you will be measuring - Amazon.com: HM Digital 716160 COM-100 Waterproof Professional Series Combo Meter, 7", White/Purple : Industrial & Scientific. There are cheaper TDS meters, but they are not very accurate the low levels you will be measuring. Distilled water I buy measures 2-3 ppm, some people have measured <1-ppm. But contamination during filling is possible, and one person reported their one-gallon jug of distilled water at ~25-ppm, although this is rare.

Distilled water I buy measures 2-3 ppm, some people have measured <1-ppm. But contamination during filling is possible, and one person reported their one-gallon jug of distilled water at ~25-ppm, although this is rare.

Distilled water does vary by brand. Here it is low cost, generally around $1.00/gallon, so I bought one of each brand and measured. I've found a range from 1.7ppm -- 4.0ppm, using the HM Digital 716160 COM-100 meter.

Thank you.Currently I'm using Nicolet brand from Premium Waters, Inc. which typically measures in the 1.4 -1.7ppm range for disolved solids. The jugs I have are sourced out of Chippewa Falls near the Nicolet National Forest in northeastern Wisconsin.

Similar threads

- Replies

- 9

- Views

- 4K

- Replies

- 311

- Views

- 60K

- Replies

- 3

- Views

- 1K

- Replies

- 56

- Views

- 24K

- Replies

- 1

- Views

- 660

| Steve Williams Site Founder | Site Owner | Administrator | Ron Resnick Site Owner | Administrator | Julian (The Fixer) Website Build | Marketing Managersing |