@tima @Neil.Antin @Bill Hart - While trying to catch up with all you’ve posted, in preparation for putting up something that outlines what I hope to achieve next in my record cleaning journey (which has been aided tremendously by @r.din ), I came across this Degritter specific thread and thought my own experiences might be of some benefit.

The Degritter MKII (can’t speak to the original) is a good machine for what it is, but obtaining optimal results takes far more passes than I suspect most prospective buyers are anticipating.

A four rotation pass (the old Heavy cycle), can work wonders, particularly on the higher frequencies. Thus, the numerous accounts of new users relating how the sound “opens up.” In my experience this benefit was easily heard regardless of what I did to pre-clean the record, be it an over-the-sink process along the lines of what Neil’s detailed in his book, or using a VPI MW-1 Cyclone. It’s easily heard even after using the VPI MW-1 and Jim Pendleton’s AIVS 3-step process. While I’ve run several hundred records through the Degritter, at least 50 records were previously cleaned on the VPI. I auditioned many of VPI cleaned discs before and after running a Heavy cycle and the difference on the high end is almost always striking.

But - using my ears and my system, the Degritter MKII will continue to move toward more accurate sound reproduction for several more cycles. With the exception of some new pressings, I’ve regularly experienced improvements after four Heavy cycles (16 rotations). Because the improvements are gradual, cumulative, I’ve become much more aware of what to listen for & so if a disc doesn’t seem to “be quite there” after four Heavy cycles, it will get two more. More often than not, those additional cycles do bring the magic. Again, this is my experience only.

I can’t speak to exactly what is going on here, why instead of hearing a general improvement, an equal raising of all frequencies with each subsequent cleaning cycle, auditioning after each cycle I hear first the highs, then some of the lows, then the a “hole in the mids” gets filled out, but over and over again, it does happen and if nothing else, it really has helped to train my ear. Once all of the undulations the stylus tracks to reproduce the entire performance are equally clean, the original mix becomes apparent, the true quality of recording rises out of the muck, if you will.

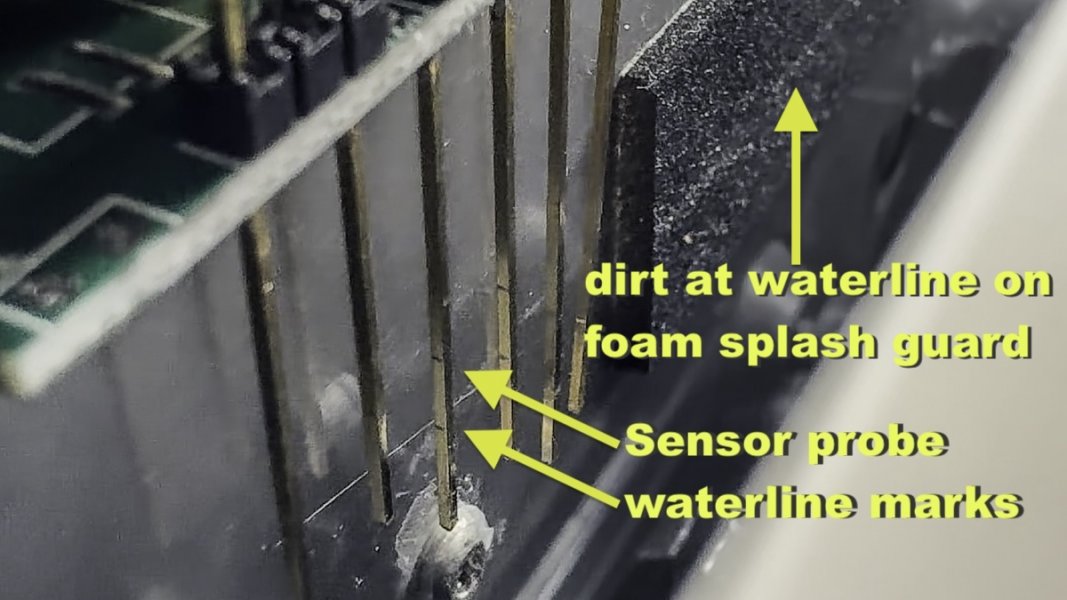

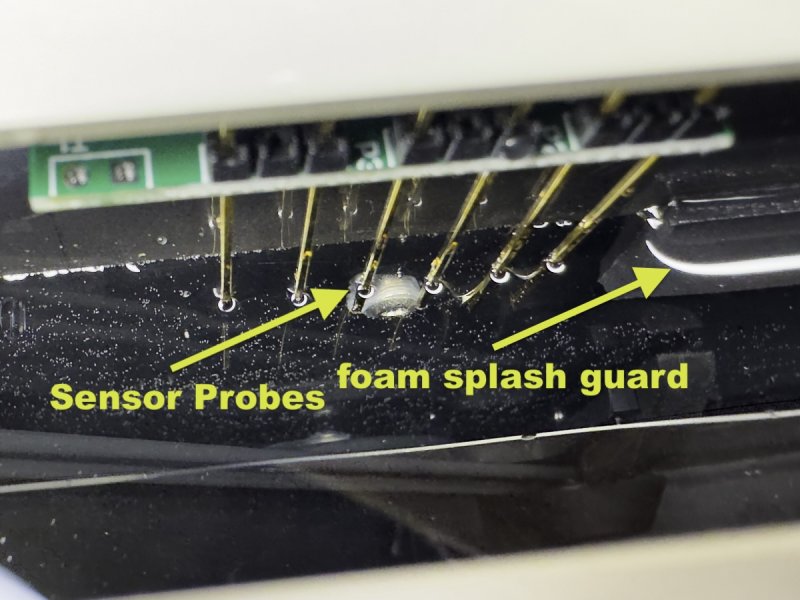

Keeping the Degritter clean is paramount and not as easy as some may think (see pics). Also, not as easy as Degritter initially thought, given the update to their latest manual significantly increases the vinegar concentration recommended for cleaning and now includes much stronger language about the need to stick to the cleaning routine. They now go so far as to state not cleaning the machine as prescribed will void the warranty.

Further, while Degritter recommends cleaning after every 200 cycles (four filter changes), they don’t speak to cleaning the filter well, filter screen, wash tank at the water line (bath tub ring), the water sensor probes, or the two foam splash guards. Getting to these components isn’t terribly difficult, but it’s best to have good light and proper tools to clean them.

The Degritter design places multiple moving parts in the wash tank. Manual cleaning of some of the nooks and crannies is next to impossible. You can, however, direct streams of distilled water to flush them out.

Because the filtration system is woefully inadequate, I tend to dump my wash water before it reaches 3 PPM. I know this is far below what is generally considered necessary, but I’m as concerned about keeping the machine’s internals clean as I am about the possibility of re-depositing contaminants onto a record. My COM-100 registers my deionized water at 0.2 -.03 PPM, and I routinely get about a .1 PPM rise per Heavy cycle. Consequently, I seldom get more than a few records through the machine before I refresh the tank.

Because the subject of whether deionized water is appropriate for cleaning comes up from time to time, I should add that the deionized water I use may be called that, but it’s actually run through multiple steps. It’s what the PureFresh system installed in Whole Foods and other retail outlets supplies. I spent some time reading about the water on the manufacturer’s web site before deciding it was suitable for my purposes.

I also do a great deal of pre-cleaning, not because I’ve found some process or cleaning agents that reduce the number of Degritter cycles I need to achieve satisfactory results (I haven’t, but not for lack of trying), but because introducing any more detritus into a system that can’t effectively clean it all out doesn’t seem wise.

For instance, pre-cleaning a record seems to remove most tar and nicotine, substances the Degritter is able to remove as well, but likely deposits on inaccessible machine internals that aren’t subjected to the ultrasonics during routine cleaning. This ventures into the realm of things I can’t prove, but given even after multiple IPA soaks my Degritter filters still show hints of yellow-brown, I’d rather work on the assumption there is the potential for internal buildup in the plumbing, valves and pumps, so a good pre cleaning just seems a wise preventative step.

Another downside of the Degritter MKII is its inability to dissipate heat quickly enough to allow multiple Heavy passes in quick succession. The machine’s cooling fan that normally comes on after two cycles cannot keep the temperature from rising past threshold. Even adding the “soak” mode to a Heavy cycle, I’ll easily trigger the cooling cycle (water circulates, record rotates, but ultrasonics are shut down) after two Heavy cycles.

Note that this is a common problem, one some users mitigate to some degree by switching tanks, adding bags of ice, etc. Because the machine itself banks a lot of heat, users report that simply switching tanks only buys so much time. In my experience, the only real solution is to either run the 2-rotation Medium setting + soak instead of the Heavy + soak (the shorter ultrasonic cycle, coupled with the more frequent soak generally keeps the machine temp stable), or to just let the machine sit idle until it returns to room temperature.

I’ve had people state that since Degritter called the four rotation cycle the “Heavy” cycle and included narrative suggesting that cycle should only be needed for very dirty records, that there’s no way my running four Heavy cycles could possibly be of any benefit. My opinion is that Degritter programmed the machine to run the most cycles it possibly could before the bath would heat up past its design limits, a limit Degritter says was set to protect the record. If the machine could operate continuously for more cycles, I believe Degritter would program it to do so. Note that Degritter refers to the ultrasonics as removing contamination "in layers." It’s also telling that Degritter has now dropped the “Low / Medium / Heavy” verbiage entirely.

The Degritter’s fan dry system works well. I normally do 2:30 to 3:00 on the lowest setting, the longer time when the bath temp is still relatively low. Once the machine is operating at max temp, I find discs will air dry without the fan in less time than that. I prefer to air dry after my final rinse. YMMV based on relative humidity in the room where you're working. My room's humidity is never above 48% and for most of the year is considerably below that.

One might read this and conclude I’m not satisfied with the results I obtain from the Degritter. That’s hardly the case. A record run through multiple cycles using an appropriate cleaning solution (I use AIVS ultrasonic enzyme concentrate) can sound so indescribably wonderful I won’t even try to do so. What I’m not satisfied with is the time it takes to obtain those results, the amount of time I need to be personally involved in the cleaning process and the time it takes to clean the machine itself.

As for the unit’s operational life, all I can say is my unit now has 2,600 cycles on it, so I’m crossing my fingers at this point.

Consequently, while I expect to continue to use the Degritter MKII as a 120 kHz rinse machine, I’m now looking at following in Tima’s footsteps, specifically the Elmasonic P-120 married to an original 1 RPM VinylStack I still have on hand from my first foray into ultrasonics. The actual unit was sub par and consequently was returned within a few days.

Long winded as this is, I’m sure I’ve left something out.